How to make decoupage on the old furniture with their own hands.

How to make decoupage on the old furniture with their own hands.

How to make furniture for the bathroom with their own hands

Any sanitary unit, whether it is a separate bathroom, or combined with a toilet, must be equipped with at least a minimum amount of furniture. The most popular furniture products that are used in rooms of this type are the cabinet, which is often mounted sink, wall cabinets or shelves, as well as a closet for the maintenance of linen. The range of choice of sets for baths in specialized stores and markets is very large, however, creating an interior with your own hands has several advantages over buying a finished thing.

White bathroom furniture in the Scandinavian style

Content

Pros of self-made furniture

Among the positive aspects of the manufacture of bathroom furniture with their own hands are the following aspects:

- Cost savings. As you know, the prices of materials are not less than half the cost of the product. Self-production of furniture will help save a significant amount of money.

- The uniqueness of the product. Personal creation of the interior element will allow you to get a piece product that can become a highlight of the design work.

- Flight of fancy. There are no restrictions on the appearance and functionality of the furniture.

- An opportunity to make furniture for non-standard room sizes.

The choice of design and furniture design

To determine the optimal set of bathroom furniture, as well as its design and construction, it is necessary to build on several factors, including the size of the room, its overall style and the financial capabilities of the home craftsman.

- Tumba For convenient storage of detergents and other household trifles of daily storage is a great bedside table. Depending on the area of the plumbing unit, it is possible to install a separate pedestal or combine it with a washbasin. In the first case, the furniture has a large capacity, while in the second it hides the sink siphon and other plumbing communications.

Bathroom cabinets are a good place to store necessary items.

- Shelves and hanging cabinets. These elements of the interior can be as an alternative to a bedside table in the bathroom, and become “roommates” in the room. It all depends on the size of the room and the needs of users. If you choose one of the two, the hanging elements of furniture look more rational, since it is much easier to find free space on the wall. Suspended cabinets can be equipped with mirrored doors, thus obtaining two useful interior elements in one.

Open shelves and racks for the bathroom allow you to quickly find everything you need, but they require orderliness and beautiful decor.

- Cupboard. Under the conditions of most standard plumbing fixtures, it is quite difficult to find a full-fledged place for a linen closet. An exit can be a small size floor corner cabinet, which does not take up much space, and at the same time allows you to place a sufficiently large number of items on your shelves.

Green cabinet-case for the bathroom allows you to fit the necessary things, hygiene items and household chemicals

The more the design and the more difficult its desired functionality, the more skill is required from the master in the manufacture of bathroom furniture with his own hands. Therefore, if the item will be made for the first time, you should not take on complex modular headsets.

Required materials and tools

The main requirement for furniture in the bathroom is moisture resistance. Today, the three most popular types of materials are most popular.

- Waterproof fiberboard and chipboard (fiberboard and particleboard). Fiberboard looks more beautiful and has a wide range of patterns. Chipboard is more resistant to water and easier to machining. The variant with a combination of these materials is possible (the case from a chipboard, finishing of facades from DVP).

A set of furniture for the bathroom with a body of laminated chipboard and facades of moisture-resistant MDF

- Plastic. Plastic products are absolutely not afraid of water and chemical detergents. The material is light and inexpensive, however, quite fragile, therefore not suitable for all furniture options. It will make an excellent hanging cabinet, but due to the weight of the sink, the bedside table can simply break.

Plastic is aesthetic, easy to clean, absolutely not afraid of moisture

- Stone and glass. Products made from these materials are of high quality, beautiful and durable, but working at home with them is rather difficult. For high-quality glass processing (and especially stone), there should be a lot of special equipment in the arsenal of home craftsman tools.

The glass fits perfectly for the bathroom, it is practical, moisture-resistant, incredibly attractive

- Natural wood. Beautiful, but expensive and impractical material. Wood furniture looks stylish and impressive, but poor resistance to moisture greatly reduces the operational life of the finished product;

Wood furniture for the bathroom looks beautiful, suitable for most styles, but not very practical

- Metal. Variants of furniture made of metal (usually steel or aluminum) are possible, however, they are quite rare. Their unpopularity is due to the difficulty of metal processing in the home, as well as the fact that such furniture is always cold.

Metal bathroom rack

In addition to the selected material for making home furniture for the bathroom, you will need various consumables (screws, corners), accessories (handles, hinges, closers, etc.), as well as a basic set of tools.

Required materials, fixtures and fittings

Among the main tools you can select a drill or screwdriver, jigsaw, tape measure or ruler for measurements, a knife. If, after manufacturing, the finished furniture is planned to be painted, you will additionally need a set of necessary paints and tools (roller, brush or spray).

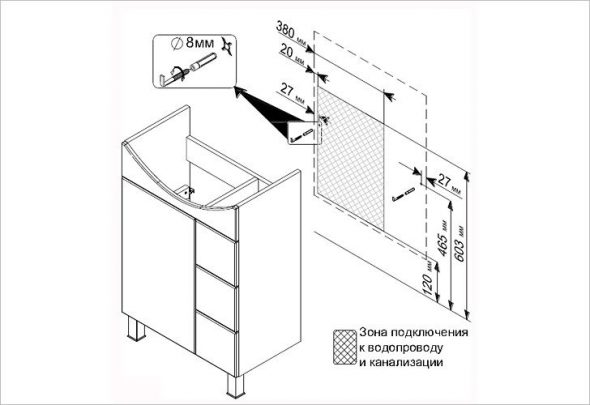

Detailed scheme of mounting cabinets under the sink

Manufacturing procedure

The project for the manufacture of cabinets for washbasin do it yourself

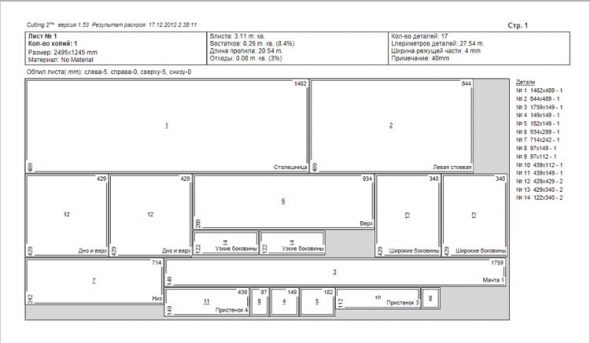

Map cutting details cabinets under the sink

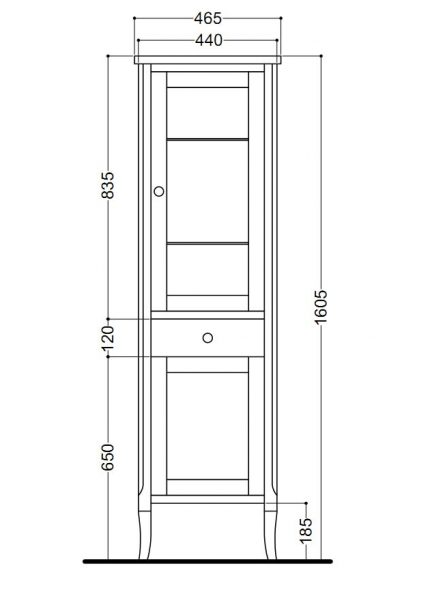

Drawing of a homemade wardrobe in the bathroom

The first stage in the manufacture of furniture with your own hands is the design of the future headset. To do this, it is necessary to take measurements of the room itself and determine the place of installation of the finished product.

Ready-made homemade cabinet in the bathroom

Having decided on the size and material, it is necessary to make parts for assembly.

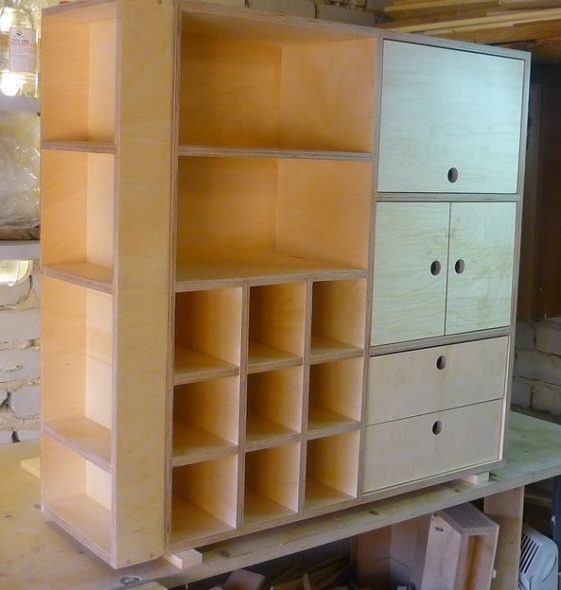

Laundry box and spruce board cabinet in the bathroom, made by hand

Cutting blanks made strictly according to the drawings, since even the smallest deviation in the cutting will lead to a poor appearance of the furniture and in many respects spoil the functionality.

Homemade version of the table-cabinets under the shell sink, which was made of wood and put on extra legs

The next stage is the assembly of parts into a single structure. Modern fasteners (confirmatories, Euros and shkanty) are the most rational option.Then the hardware is installed.

The option of making cabinets for two built-in sinks with your own hands

On the choice of handles and hinges do not save money, so the option with plastic parts is better to immediately set aside (they will very quickly become unusable). The ideal choice is chrome metal fittings, which not only will please the eye with its appearance, but also will serve its users for quite a long time. The final stage of manufacturing is lining and decoration.

Step-by-step photo instruction for collecting cabinets under the sink with a tabletop

Decoration and decor

Homemade convenient and functional bathroom cabinet made of waterproof plywood

The final appearance of the finished furniture depends on the fantasy of the home craftsman. The simplest option is pasting products with a polyvinyl chloride film.

Self-adhesive film for decorating furniture under the tree

The range of such stickers is very large, so there will be no problems with the choice of color and ornament. Another positive quality is the resistance of PVC films to moisture, which is important for the conditions of the sanitary unit.

Bathroom furniture decor with self-adhesive film

If desired, the set can be decorated with handmade products. The main thing is that they do not become limp with moisture over time. An interesting option with the installation of a mirror with lights, which to save space can be placed on the cabinet door.

Decorating the shelves in the bathroom using decoupage technique

Conclusion

Furniture in the bathroom, made by hand: shelves, cupboard under the sink and mirror

Beautiful and functional furniture in the bathroom is not difficult to make yourself. Manual work will not only save an impressive amount of money, but also create a unique creation that will become a real highlight of the interior. The main thing is to have the desire, ideas, small building skills and a standard set of tools. Do not immediately grab onto the manufacture of modular furniture, it is better to start with simple shelves, eventually improving their skills and moving on to more complex structures.

Handmade wooden dresser under the sink with side shelves

Video: Do-it-yourself furniture in the bathroom

50 ideas for making furniture in the bathroom:

How to make decoupage on the old furniture with their own hands.

How to make decoupage on the old furniture with their own hands.

How to make a folding chair with your own hands?

How to make a folding chair with your own hands?

How to clean furniture from scotch with improvised means

How to clean furniture from scotch with improvised means

What kind of wood do furniture: expert recommendations

What kind of wood do furniture: expert recommendations

Arrangement of furniture by Feng Shui will make you happier

Arrangement of furniture by Feng Shui will make you happier

Furniture for the hallway with a narrow corridor.

Furniture for the hallway with a narrow corridor.