Sliding table - saving space and a stylish interior solution

Sliding table - saving space and a stylish interior solution

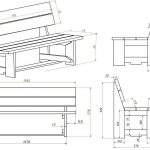

We create a table-bench transformer with your own hands

Everything that is done independently is always interesting and pleasant. In addition, the "homemade" give the possibility of flight of fantasy and the realization of the most daring ideas. Especially a lot of space for creativity among those who have at their disposal a summer cottage.

"Homemade" give the opportunity to fly fantasy and implement the most daring ideas.

One of the wonders of home craftsmanship is the bench bench transformer, which can be made with your own hands according to ready-made drawings or drawn by yourself. It is best to use millimeter paper: on it the scheme of such an unusual product will be executed most accurately.

One of the wonders of home craftsmanship is the bench transformer table.

Depending on the ideas about the capabilities of the transformer, make drawings; their preparation takes into account all the advantages that this product will provide:

- it is compact and takes up minimal space, which will be an additional advantage in small areas;

- it can easily be moved to any point;

- universal in use, as it turns into a set of wide use.

Content

We determine the design and construction

The transformer can be provided with one or two benches, with backs and armrests, or without them. Their size will also determine the home master, based on the needs of the family and their own creative vision.

It is best to use millimeter paper: on it the scheme of such an unusual product will be executed most accurately.

To make the product strong and durable, you need to choose the right lumber.

For work you will need:

- edged boards;

- wooden beam.

The product is compact and takes up minimal space, which will be an additional advantage in small areas.

At the same time, experienced owners claim that beech, ash, oak or birch wood will be suitable. You can use a pine, but you have to choose very carefully, avoiding blanks on which there are many knots.

Prepare the tools

Universal application, as it turns into a set of wide use.

To keep things moving without stopping, and time was spent as efficiently as possible, it is important to prepare the tools, not forgetting any trifle:

- desktop trimming machine: greatly facilitate the work; you can perform operations and manually with a small-toothed hacksaw, and use a protractor for marking;

- electric drill and drill;

- Planer or chamfering machine;

- Phillips screwdriver;

- sanding small installation or sandpaper bar;

- rasp.

The transformer can be provided with one or two benches, with backs and armrests, or without them.

Additionally, PVA glue and wood screws can be useful.

Manufacturing process: step by step instructions

Reliability and durability of operation depends on accuracy and sequence of performance.

A design idea can be widely developed when the time comes to decorate, especially for this, the backs of shops and seats.

To ensure that all parts of the product were at hand, the masters recommend before starting to work on the drawing, where its elements are indicated, immediately prepare the legs (8 pieces) up to 70 cm long, making oblique cuts on them at the bottom and top.

Reliability and durability of operation depends on accuracy and sequence of performance.

The next step is to make the worktop. You need five planks in dimensions defined by the drawing..

There are many ways to make a homemade design incredibly attractive and original: it all depends on the desire and effort, and success will come!

They need to be sanded and joined with slats eight centimeters wide. Two connecting parts is enough.

All connect screws.

When the bench is ready, countertop screwed to it.

So that all parts of the product were at hand, the masters recommend before starting work on the drawing, where its elements are indicated.

If you intend to design with two seats, you can begin to manufacture the first; its value depends on the general parameters of the product; according to the drawing it is made of boards (1-2 pieces); their number corresponds to the width of the bench.

- The seats are screwed to the legs;

- below they are reinforced with struts.

The next step is to make the worktop.

The second shop is made similarly:

- legs are made from 40x40 bars; they are attached to the seat in the shape of the letter "A";

- parts of the bench are connected with a bar, strengthened for durability with wood glue and self-tapping screws;

- if it is assumed that a back is attached to the bench, it is made of planks, reinforced with bars, struts, carpenter glue and self-tapping screws.

The next step is to assemble the prepared parts of the product.

The next step is to assemble the prepared parts of the product. To avoid unpleasant surprises, it is necessary to assemble a transforming table, alternately connecting the elements together and referring to the drawing.

A design idea can be widely developed when the time comes to decorate, especially for this, the backs of shops and seats.

The nuance that attracts attention is the observance of the same height of parts. If everything is done correctly, in accordance with the drawing, after the completion of the work you will see a lovely sofa.

If everything is done correctly, in accordance with the drawing, after the completion of the work you will see a lovely sofa.

The back must be securely strengthened; for this purpose, holes are drilled in the joints where the furniture bolts are screwed.

If it is assumed that the bench bench transformer will be located on the street, to increase the strength and longer life is worth painting and varnish.

Then check the correctness of manufacturing and strengthening the backrest-table tops.. A simple reliable way to check will be opening and fixing with a regular stick.

Then check the correctness of manufacturing and strengthening the backrest-table tops.

If everything opens and closes without difficulty, without much effort, the shops are connected to each other.

They are fixed with wooden dowels or glued with carpenter's PVA.

For complete convenience and comfort, you can mount the armrests. For their manufacture you need:

- two plates for stands;

- four - for mounting to the seat.

If everything opens and closes without difficulty, without much effort, the shops are connected to each other.

They are fixed with wooden dowels or glued with carpenter's PVA. To complete this part of the work you need to make a kind of lever that allows you to freely fold and unfold the transformer.. You will need a timber fixed with furniture screws and nuts, and it is connected to the armrest with self-tapping screws.

Additionally, PVA glue and wood screws can be useful.

If the calculations are done correctly and the details are connected correctly, you get a wonderful table with two attached seats, which can be easily disassembled and assembled.

You will need a timber fixed with furniture screws and nuts, and it is connected to the armrest with self-tapping screws.

Dressing

If it is assumed that the bench bench transformer will be located on the street, to increase the strength and longer life is worth painting and varnish.

A design idea can be widely developed when the time comes to decorate, especially for this, the backs of shops and seats. You can decorate them:

- drawings painted with colored acrylic paints and varnish;

- decoupage pictures;

- cute figures of funny animals inflicted by an electric burner;

- jigsaw saw out a beautiful floral ornament or figurines of heroes of favorite fairy tales; attach them with glue and screws to the backs.

That business moved without stops, and time was spent as much as possible effectively, it is important to prepare tools.

There are many ways to make a homemade design incredibly attractive and original: it all depends on the desire and effort, and success will come!

Experienced owners claim that beech, ash, oak or birch wood will be suitable.

VIDEO:How to make a table transformer do it yourself

50 photo ideas of transformer bench tables

Sliding table - saving space and a stylish interior solution

Sliding table - saving space and a stylish interior solution

Making a table decor with your own hands

Making a table decor with your own hands

Retractable table in the interior of a small kitchen.

Retractable table in the interior of a small kitchen.

How to make a computer desk with your own hands

How to make a computer desk with your own hands

Making a folding picnic table with your own hands: drawings, tips

Making a folding picnic table with your own hands: drawings, tips

Why you need to take into account the size of the kitchen table in the interior

Why you need to take into account the size of the kitchen table in the interior

An overview of bed accessories: types, materials and functionality29

An overview of bed accessories: types, materials and functionality29

The current trend of IKEA - wardrobe-bed transformer21

The current trend of IKEA - wardrobe-bed transformer21

Safe sleep with a side for a children's bed from Ikea16

Safe sleep with a side for a children's bed from Ikea16

What to choose: the orthopedic basis for a bed or flat continuous?13

What to choose: the orthopedic basis for a bed or flat continuous?13

Lifting bed with sofa: advantages and disadvantages8

Lifting bed with sofa: advantages and disadvantages8