Table with glass table top do it yourself

Table with glass table top do it yourself

Sliding table - saving space and a stylish interior solution

Beautiful folding round wooden table for the kitchen-dining room

The tiny Soviet-style kitchens are not able to accommodate furniture and appliances necessary in this room. Put the usual kitchen table, already a problem, it will clutter up all the space there. The only possibility to somehow solve this problem is to use instead of the usual sliding table.

Kitchen extendable table in folded and unfolded form in the interior of the room

Sliding dining table - the secret of good hospitality

Usually, furniture is bought in a store, but our people have long found another way out - to make it with their own hands. Really spending about twenty thousand rubles for, in general, a simple thing is somehow stupid, if you can do it yourself.

DIY handmade kitchen furniture

Wooden oval extendable table with a set of chairs

The desire to make a sliding table gives rise to many problems and the first of them prompts the master to decide which table he needs? If you do not take into account very very exotic models, then all the tables known to us are divided into two types: round and rectangular.

Rectangular folding table for permanent use and for guests

Folding round table made of natural wood after folding becomes oval and can accommodate more people

A round, or rather sliding, oval table is the reality of the everyday life of modern people, making this oval is no more difficult than making a rectangle.

Oval glass sliding table in a modern interior

Another thing is when you set yourself the task to make a sliding table of the correct round shape, including in the moved apart state. It is difficult to assemble such a piece of furniture, the number of its components is too large and this will require solving a number of engineering issues or using other people's solutions, which will not lead to a significant simplification of the work ahead. Such practical tasks are not peculiar to a practical person, he follows the path of least resistance.

A round extendable table, which, if necessary, doubles the area of the tabletop and remains round

The path of least resistance, in this case - is the manufacture of a rectangular or oval (in the shape of an irregular circle) sliding table. A round table will take too much precious space indoors, so most craftsmen prefer a rectangle, and it’s easier to find suitable materials for it.

Rectangular sliding glass table

Next, you need to decide on the material. Due to the high cost and complexity of processing the wood will have to abandon oak tabletops and legs. The table top will be made of laminated chipboard, and metal legs can be purchased at the store. Laminate for the countertop fits perfectly, because it looks stylish and beautiful, besides the laminated surface of the table repels moisture.

Waterproof laminate, which is suitable for the manufacture of countertops

Furniture metal legs are ideal for a made table.

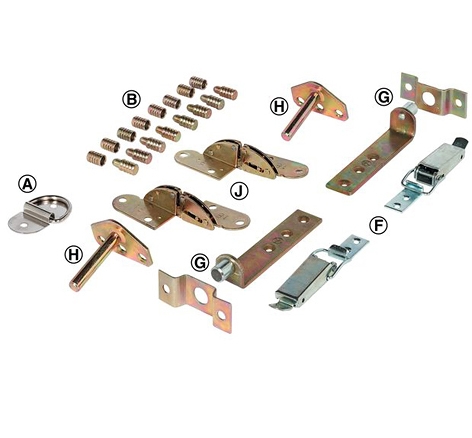

In addition to pieces of laminate and metal legs, you will need many other details, among them:

- four aluminum corners with a length of at least fifty centimeters each;

- a pair of telescopic guides, the length of which coincides with the corners;

- dowels with a diameter of 8 mm and a length of 40 mm;

- screws with a diameter of 4 mm and a length of 20 mm,

- bolts, nuts, glue and material for finishing the edge of the tabletop.

Additional accessories for table assembly

Self-tapping screws should be significantly shorter than the thickness of the future table top. The main tools for assembling the table will be a drill and a screwdriver. However, the screwdriver can be replaced with a screwdriver. The process will become more laborious, but the satisfaction of the work done at the finish will be no less.

Content

Step by step instructions for the manufacture of sliding table

Device worktop from laminated chipboard

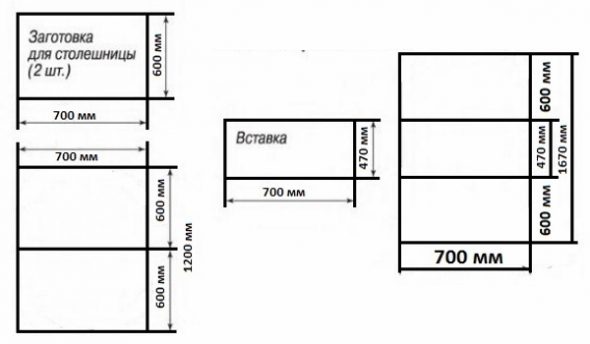

- The process of assembling the sliding table should begin with measurements. The first thing to measure is pieces of laminate. There should be three equal to the width of the piece. Two of them should be the same length, the third - shorter. They should be spread out on a flat surface so that the short piece is between two identical ones, align and measure all the place. Their total length will be the length of the spread table, it is important that it fit in the kitchen or in the room.

Cut out the details of the future table top according to the drawing

Drawing table top

- In order for the table design to be solid, both in the spaced and in the shifted state, at least two holes with a diameter of 8 mm and a depth of 20 mm must be drilled at the end of each piece of laminate from the inside. The holes in the insert should be drilled from two sides. The holes on one board must completely coincide with the holes on the other two, when they are connected to each other. Then, in the holes of the first board, it is necessary to glue forty-millimetric dowels on the glue so that they are seated there tightly. The same should be done with the holes on one of the sides of the insert. Now you can connect the pieces of laminate to each other. Dowels protruding from the end of one board will freely enter the holes of another

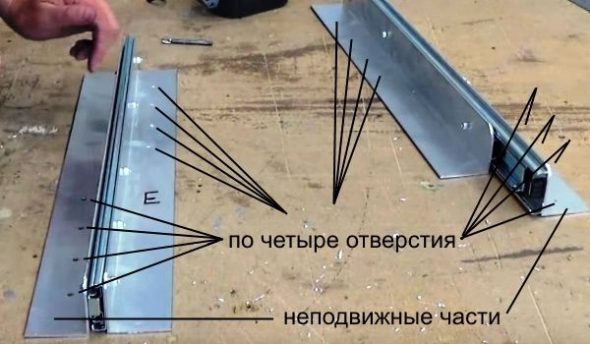

- Then you need to measure the length of the corners and mark on one of the sides of each of them the middle and points of the future holes that need to be drilled with a drill. At the two corners of the hole should be located to the left of the middle, and the other two to the right.

We drill holes in the corners

- Telescopic guides consist of two parts, while one of these parts is placed in the other and moves freely inside it. They need to be separated and bolted to the aluminum corner so that the wide, fixed, part of the guides is attached to the corner with the holes on the right, and the narrow one is attached to the corner with the holes on the left.

We attach the parts of the guides to the corners, mark the holes and drill through

- The second telescopic rail must be connected to the second pair of corners in the same way. It remains only to screw the guides to the two main pieces of laminate with screws. In this case, the wide parts of the guides should be attached to one part of the tabletop, and narrow to the other. Thus, it turns out the sliding mechanism, which allows to significantly increase the area of the table, then when it is necessary and return it to its normal state, if the need for a large table has disappeared.

Angle structures with movable and fixed guides

The movable side is fastened to the right side, the fixed one - to the left side of the tabletop

- Freely extending table is convenient only in cases where it is increased in size at the request of the owners. To avoid spontaneous retraction, you can, if you install on all parts of the tabletop simple locks that hold the halves of the table together.The additional insert is held between the left and right half of the tabletop, not only due to the four dowels, but also due to the sliding mechanism (on which it lies) tightly bolted to the tabletop.

On each side of the table fasten the lock with screws

- In order to attach the legs to the table, first you need to fasten on its inner surface, the so-called heels, to which the legs are then simply screwed. Heels are attached to the table top with twenty millimeter screws.

Self-fastening the legs to the tabletop

Kitchen table on purchased metal legs legs

Finishing touches

Simple folding table with chrome legs

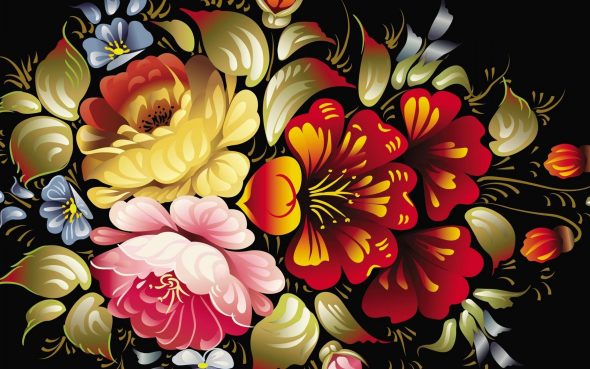

A kitchen table of this design can become a gathering place for a large family in the evenings or a center for a festive event (birthday, wedding anniversary, etc.). However, old laminate itself is unlikely to inspire people for a long feast. It is a different matter if you lightly decorate it. It turns out that the laminated surfaces after some processing can be painted and even painted on them. In order to achieve the desired effect, you need quite a bit. To glue the butt of the table top with edge tape, no matter what color, just to close the ugly butt. Sand the surface with sandpaper, treat dents with putty and coat with acrylic paint. Paint can be any color: from white to black. The image of flowers in the style of Zhostovo trays is put on the black background of the table, turning the sliding table, an ordinary utilitarian thing, into a work of art. Handwork always risks becoming art, the master who creates it is always the creator.

Examples of painting in the style of Zhostovo “Flowers” on a black background

Video: Do-it-yourself folding table

Table with glass table top do it yourself

Table with glass table top do it yourself

Unique dressing table do it yourself

Unique dressing table do it yourself

How to paint the table yourself?

How to paint the table yourself?

Making a desk with your own hands: the manufacturing process

Making a desk with your own hands: the manufacturing process

Choosing a table for makeup with a mirror

Choosing a table for makeup with a mirror

The infinity table is a stylish solution for a modern interior.

The infinity table is a stylish solution for a modern interior.