Making a glowing table with your own hands: the advantages of creating

Making a glowing table with your own hands: the advantages of creating

The advantages of creating a table-book with their own hands

You can make a table book with your own hands, independently developing and implementing its appearance, while saving a significant part of the money. However, you should not dwell on the standard model, you should select the table design for your home, modify and improve it, thereby developing your skills.

You can make a table book with your own hands on your own.

If desired, the table-book can become a transforming table and accommodate additional chairs, a mini-bar, and even drawers for dishes.

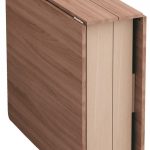

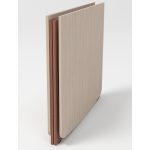

The table-book is a portable compact piece of furniture, which through simple operations turns into a table of standard sizes. Such furniture is perfect for studios, lofts and just small apartments, whose owners are trying to organize the space around them as compact as possible.

Such furniture is great for studios, lofts and just small apartments.

The shape of the table top can be square, rectangular or rounded.

A table may have several legs, or another design that allows it to maintain stability.

Currently, in furniture stores there is a huge selection of a variety of tables, books. However, there are reasons why people prefer to make furniture with their own hands, rather than buying it.

- The quality of the furniture. Not all that comes from the conveyor, quality. Material, coating, accessories, fixtures - all this should be paid attention to when buying a table, so as not to regret afterwards the money spent;

- Price. From the first reason the second follows. As a rule, high-quality, well-made furniture has a corresponding price. Between the price-quality factors that influence the purchase, people often choose the “price”, by virtue of their wealth, buying lower-quality, but cheap goods.

- Appearance. Despite the wide range of tables, books in stores, a big problem may be the choice of suitable for a particular apartment. Size, shape, color, accessories - many find it easier to make their own dreams come true, to do everything with their own hands, rather than continue to look for the perfect piece of furniture.

The table-book is a portable compact piece of furniture, which through simple operations turns into a table of standard sizes.

When choosing a design for a future product, you must take into account your personal characteristics, as well as the characteristics of your family and home.

And you can make a table-book yourself without possessing special skills. However, before proceeding directly to the manufacture, it is worth considering everything to the smallest detail.

Currently, in furniture stores there is a huge selection of a variety of tables, books.

Families with young children first need to pay attention to the most sustainable models.

Edges are decorated with an edge.

Content

Design

There are many types of tables, books.

- The simplest consists of a central part, a tabletop - one or two, and legs. Usually, in the folded state, the legs hide under the central part; on the side they cover parts of the tabletop. At the right time, the cover unfolds and rests on the extended legs.

- Tables-books without the central part - have a smaller size, but they are more compact when folded. These tables take up little space, consume little material, and can be made with your own hands.

- Tables with folding chairs hiding under the table top. This kit is a great solution for a studio apartment. Similar, more intricate elements of furniture require more material consumption during their creation, certain skills, as well as a larger area of the room.

- With shelves or drawers. It combines a place for eating and a bollard.

- Table transformer. If desired, the table-book can become a transforming table and accommodate additional chairs, a mini-bar, and even drawers for dishes.

Despite the wide range of tables, books in stores, a big problem may be the choice of suitable for a particular apartment.

Choosing materials, you must rely primarily on the calculated amount and the planned durability of the product.

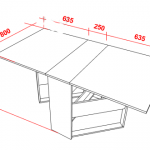

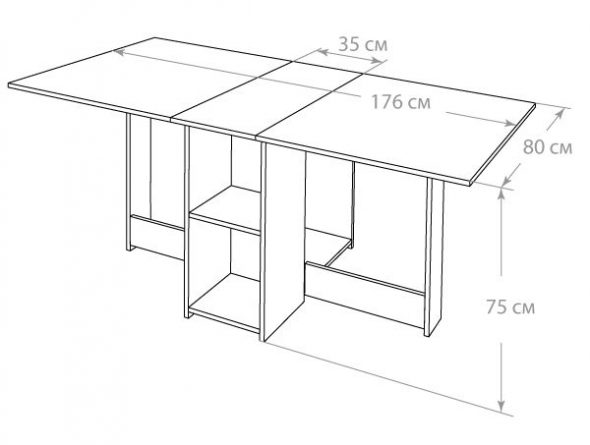

The shape of the table top can be square, rectangular or rounded. The legs can be on wheels for better unfolding. A table may have several legs, or another design that allows it to maintain stability.

It is possible to make a table-book independently without possessing special skills.

The simplest folding table consisting of the central part, two table tops and four legs is used as an example.

The sides and legs can be provided with rubber or felt pads.

When choosing a design for a future product, you must take into account your personal characteristics, as well as the characteristics of your family and home. Large families or lovers of noisy gatherings will need a large table with several folding chairs. Families with young children should first of all pay attention to the most stable models that a small child cannot decompose and drop onto himself. For such families also suitable rounded table top.

However, before proceeding directly to the manufacture, it is worth considering everything to the smallest detail.

It is impossible to proceed with the drawing and the subsequent work without having an idea of how the result should turn out.

Materials and tools needed for manufacturing

Choosing materials, you must rely primarily on the calculated amount and the planned durability of the product.

The simplest consists of a central part, a tabletop - one or two, and legs.

A drawing is constructed according to the finished sketch.

Table-book with your own hands - what will it take? The simplest folding table consisting of the central part, two table tops and four legs is used as an example. To create it you will need:

| Name | Qty |

| sheet chipboard | sheet size depends on the size of the selected table |

| loops | 10 > |

| self-tapping screws | 100 |

| edge | 1 |

| sandpaper | 1 |

| hammer | 1 |

| screwdriver | 1 |

| pencil | 1 |

| ruler | 1 |

Tables-books without the central part - have a smaller size, but they are more compact when folded.

Assembling the central part.

Manufacturing sequence

- The first stage is the creation of a sketch. It is impossible to proceed with the drawing and the subsequent work without having an idea of how the result should turn out.

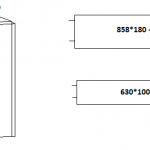

- Drawing. A drawing is constructed according to the finished sketch. He, like the sketch, should show the product in assembled and unfolded form, as well as individual parts. The drawing indicates the number of required parts and dimensions.

- Assembling the central part. It consists of a central worktop, two sidewalls or racks, and three stiffeners. First, sidewalls, a central table top or lid, and stiffening ribs are sawn from a chipboard. To attach the ribs, holes are drilled in the sides of the future table. The sides and edges are connected, the center is now fixed.

- Feet - cutting and assembly of all elements.

- The central part needs to be turned in order to attach the right and left covers to it with the help of loops.

- Fixing the legs to the central part - holes are drilled and loops are attached.

Tables with folding chairs hiding under the table top.

When assembling it is important not to forget about sanding the parts to maintain a neat and tidy appearance.

When assembling it is important not to forget about sanding the parts to maintain a neat and tidy appearance. Edges are decorated with an edge. Sidewalls and legs can be provided with rubber or felt pads, for more convenient folding, as well as prevent damage to the floor covering.

With shelves or drawers.

The central part needs to be turned in order to attach the right and left covers to it with the help of loops.

VIDEO: Desk book with your own hands

50 photo ideas: how to make a table-book with your own hands

Making a glowing table with your own hands: the advantages of creating

Making a glowing table with your own hands: the advantages of creating

We do the restoration of the table with their own hands

We do the restoration of the table with their own hands

Making a desk with your own hands: the manufacturing process

Making a desk with your own hands: the manufacturing process

How to glue the edge to the tabletop at home.

How to glue the edge to the tabletop at home.

How to make a comfortable table for breakfast in bed with your own hands

How to make a comfortable table for breakfast in bed with your own hands

We make a table transformer with your own hands

We make a table transformer with your own hands