Table with glass table top do it yourself

Table with glass table top do it yourself

How to make a kitchen table with your own hands

Such a piece of furniture as a kitchen (or as it is also called dining) table - the main component of the kitchen interior. Its shape, size should correspond to the size of the room, so that all family members can fit behind it. It is also important that the kitchen table does not interfere with the free passage.

Sliding dining kitchen transformer table

Currently, the stores offer a wide selection of kitchen furniture, of various shapes and sizes, made of various materials. On the market there are tables of both Russian and foreign production.

The original round dining table with chairs in the interior of the kitchen

When choosing a table for a small kitchen, you have to make a choice - you like when there is a lot of space, or it is important for you that the furniture be comfortable, roomy. If you just can not decide on the appropriate table in the kitchen, try to make it yourself. Who has a certain skill, do it quite well.

Handmade wooden round table with four-pillar construction

Content

The advantages of creating your own hands

Folding table for a small kitchen with their own hands

Many men who like to do their own hands, can significantly save the family budget, because the finished products are not cheap. Accordingly, you choose the material for the manufacture of a high-quality dining table and the necessary fixture. Having shown design abilities, you will collect the original piece of furniture, ideally suited to the kitchen interior.

Folding table in the kitchen, which does not take up extra space

Do not think that this is a difficult task. The assembly of the dinner table will take not so much time - just a few days. A little harder to make the tabletop. It is better to first consult with your friends involved in such matters, or read the information on the Internet.

Table with shelves and reclining table top with his own hands

Collecting a table with your own hands, you will create a unique thing, bring to life a long-standing idea. Perhaps, with your light hand, organize the production of kitchen tables, and this will develop into a profitable business.

We determine the design and construction

Round wooden table with handmade painting

Square wooden table for dining area

The design and shape of the dining table can be very diverse. Designers, applying fantasy, bring to life the most unusual ideas.

Dining table sliding oval with chrome legs

Consider the design of this piece of furniture.

| Round table | It has smooth lines, as if uniting those who are sitting at such a table. It has several legs or one big one. It is comfortable to sit behind him, you will not have an association with a place of work or study. There is one drawback - you can not put it tightly against the wall |

| Oval | A great option for owners of a large kitchen, which is divided into working and dining areas.The perfect choice for a large family, strong enough |

| Square | The embodiment of rigor, but at the same time it is simple and multifunctional. Suitable for small spaces, saves space well |

| Rectangular | Widespread option. Behind it can accommodate a lot of people. It is arranged as you like - in the center, near the wall, by the window |

| Triangular | This table is quite rare in the kitchen. It is used as an unusual element of decoration, for example, as a coffee table. |

A set of furniture for the kitchen of wood: a rectangular table, bench and corner

Dining Corner Glass Table

Owners of a small kitchen prefer to use a table-book or sliding. Since in the assembled state, they significantly save space. Other forms of tables are few where you can see. If you prefer products of the original form, it is better to make them to order.

Large classic dining table in solid wood

A kitchen table, like any other furniture, is selected for a particular interior style. For example, the usual wooden table is suitable for the classics. For high-tech, right angles and lines are characteristic, so choose tables made of plastic, metal, glass, with an emphasis on white and gray shades. For the modern style used unusual furniture with ornate lines. Eco-style means products made from natural material.

Original high-tech folding dining table

Designer Board. Whatever table you choose, as long as it matches the interior and complements the overall look.

Necessary materials

Materials for the dining table can be different. We give the most used:

- DSP;

- Chipboard;

- board glued, cut;

- timber.

If desired, they can be combined. You will also need: corners, hinges (for folding models), rollers, confirmatics, corner fasteners, eccentric bolts, legs-pads, tape for trimming, plastic profile for the table top, caps.

Required Tools

Do not do without the standard set of tools:

- jigsaw;

- drill;

- hacksaw;

- screwdriver;

- drill;

- screwdrivers;

- electric planer;

- grinding machine;

- hexagons;

- building dryer (can be replaced with an iron);

- roulette (ruler), pencil.

In the manufacture of complex models can not do without additional tools.

Manufacturing process: step by step instructions

We will make the tabletop of wooden boards

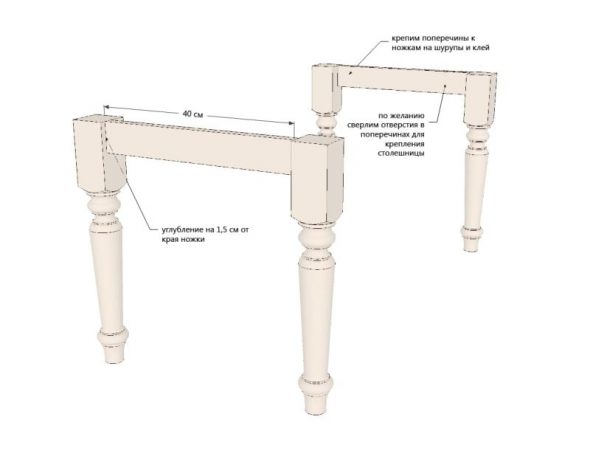

How to make a kitchen table with your own hands? Consider this on the example of a regular dinner table. First of all we prepare the tools and materials that will be needed for work.

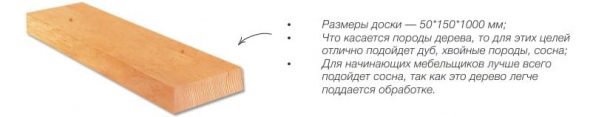

The scheme of the future dining table with dimensions

Then we make the markup of furniture elements. We start from the tabletop, as this is the largest part of the table. In shape, it can be rectangular, round, square or oval. If you have conceived to make the table of unusual shape, markup to draw on the sketches.

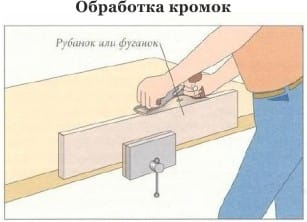

We sand the boards with a plane, carefully process the edges so that the boards lie as close as possible to each other

We join the boards with glue and dowels, remove excess glue on the surface and grind it

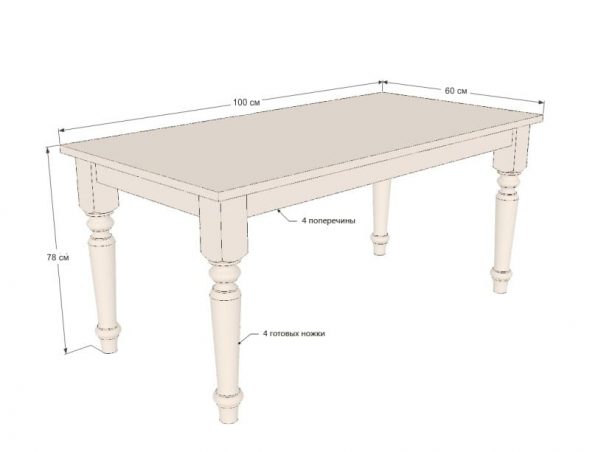

Then we apply the side racks to the material - these will be the legs of the future table. Most often, the form they imitate a chess piece. If you want, you can make other forms on your own. The main thing that the design was sustainable.

We fasten the legs and make the basis for the table top

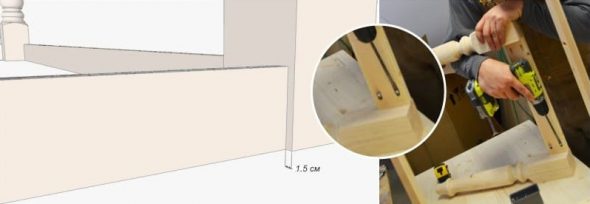

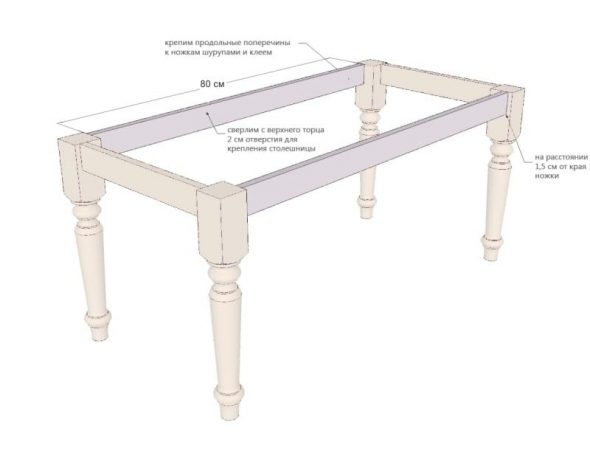

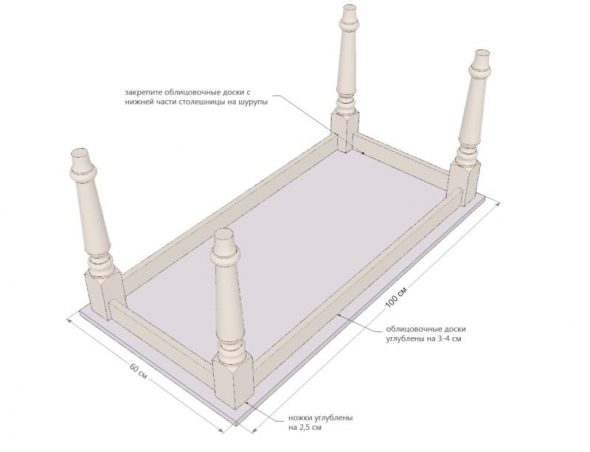

Then we perform the marking of the upper and lower rails, which will connect the racks and thereby ensure the reliability of the design. Remember that the lower crossbar is always almost twice as wide as the upper one. Her form is diverse. Usually the legs are placed from the edge of the table surface at a distance of 15-20 cm.

Fixing the crossbars of the table

At the next stage of work, we make cutting of elements. We place the material on the table. Cut the tabletop using a jigsaw. In order to avoid chipping, we place plywood under the bottom.Similarly, cut out the remaining parts. Do not allow material to sag. Because of this, the tool may break or break the cut-out element. At the end of the cutting edge of the parts we grind with a special machine or go through it with sandpaper.

Fasten the legs to the long crossbars and drill holes in them in order to install the tabletop later.

Using the tape for the edges and the plastic profile, produce facing. First, put the profile on the edge of the surface. In the place of angular bending, the profile must be heated with a hairdryer and then rotated. For high-quality fastening use universal glue.

After the glue in the frame dries, you can install the countertop on the frame

Then we make the facing of the legs and crossbars, using a tape for shaping the edge. Before this we prepare the surface, cleaning it from dirt and grease. Hot iron press the tape on the edge and glue it. With a sharp knife cut off the excess. The resulting irregularities gently remove the sandpaper. In the same way we process edges of other elements.

If you want to make the table longer and wider, then you need to strengthen it with two additional transverse planks

We assemble the table in the following order. Using confirmatics, we connect the legs to the crossbeams, positioning the upper one so as to prevent the table top from sagging. Bottom fastened at a height of 20-25 cm from the floor.

Ready assembled table it remains only to process the varnish or stain or paint, previously progrunttov

We place the table top on the finished base, fix it on the corners. Attach to the rack leg-lining. Furniture screws decorate stubs. Everything, the dining table is ready!

Ready universal option - tabletop and legs covered with stain

It is possible to paint the legs white, and the tabletop to cover with stain to make an unusual design

Video: We make the table

50 photos of the tables made for the kitchen and dining room do it yourself:

Table with glass table top do it yourself

Table with glass table top do it yourself

Table height does matter.

Table height does matter.

The advantages of creating a table-book with their own hands

The advantages of creating a table-book with their own hands

Sliding table - saving space and a stylish interior solution

Sliding table - saving space and a stylish interior solution

Making a folding table with your own hands

Making a folding table with your own hands

How to use unusual tables in the interior

How to use unusual tables in the interior