The style of the dining table in the small living room

The style of the dining table in the small living room

Making a glowing table with your own hands: the advantages of creating

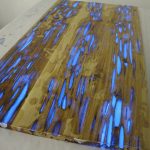

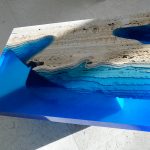

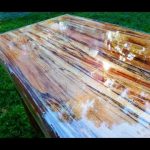

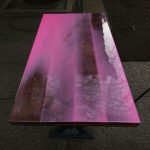

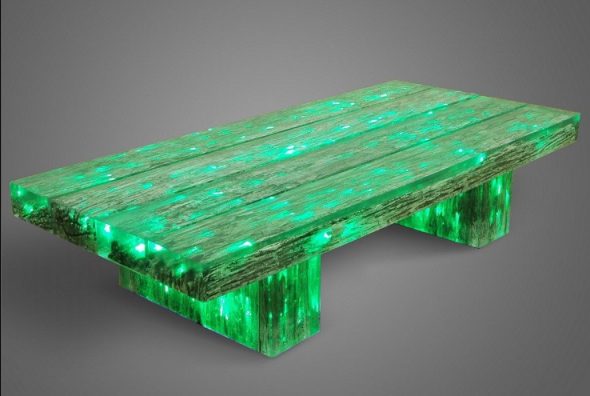

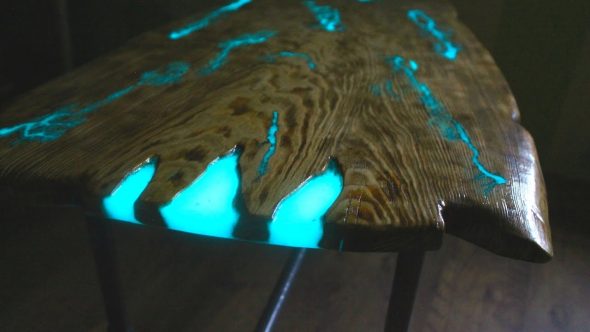

Furniture with a fluorescent effect looks unusual and especially interesting. Anyone who wants to make the interior of the apartment original or add a “zest” to the equipment of the dacha will suit just such an option - a table with “lighting”. The product is created using epoxy resin and two types of resistant paints. All work - from grinding to lining - is quite accessible to the beginner in the joinery business.

All work - from grinding to lining - is quite accessible to the beginner in the joinery business.

At desire of contrast of a support cover the paint which is different in color from the main palette.

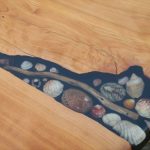

When decorating the table, you can come up with your own design, based on the quality and texture of the material.

Furniture with a fluorescent effect looks unusual and especially interesting.

Content

The advantages of creating your own hands

Making a glowing table with your own hands does not require any special material and labor costs. To handle a wooden tabletop using a special resin can anyone who knows how to hold the tool in their hands.

When decorating the table, you can come up with your own design, based on the quality and texture of the material.

Furniture with a fluorescent effect looks unusual and especially interesting.

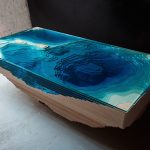

Independent creation of furniture for the cottage or at home is a great help to save the budget. Such products you can hardly see on the free market, they are usually made to order and they are quite expensive, like handmade. For the manufacture of suitable thick boards or finished wooden table with an interesting texture. Applying epoxy is half an hour. After some time, with the correct observance of all stages of processing, you will receive a table with a fascinating luminous effect.

Independent creation of furniture for the cottage or at home is a great help to save the budget.

We determine the design and construction

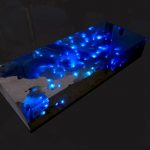

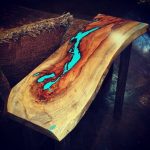

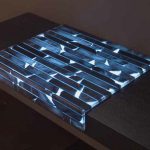

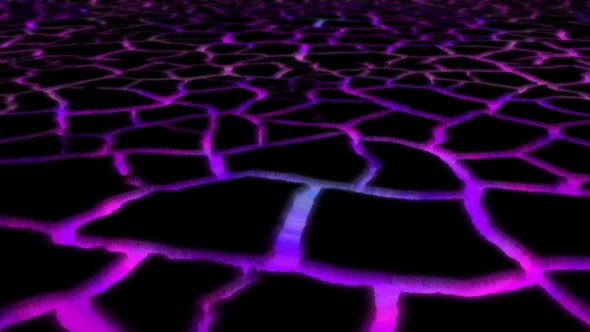

Glowing table can be made stationary or folding. When processing the stage of designing furniture does not matter. To create a luminous effect, use only the tabletop, although you can make the furniture completely with a luminous surface. Designers agree that it is better to process individual panels - this is how the product looks more interesting.

Glowing table can be made stationary or folding.

Making a glowing table with your own hands does not require any special material and labor costs.

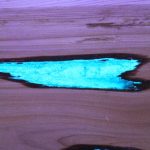

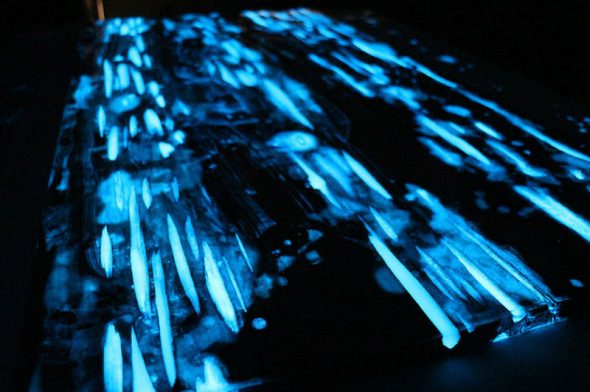

Depending on the texture, a part of the resin can be applied - on cracks, or to cover with a luminescent composition (with a light blue or other shade) the entire tabletop, including edges. Choose a "colorful" option or relatively evenly glowing is necessary based on your taste and needs.

Designers agree that it is better to process individual panels - this is how the product looks more interesting.

Necessary materials

For the manufacture of a luminous table will need the following materials:

- boards - 2 pieces (40-50 cm wide, 1-1.2 m long);

- epoxy resin;

- adhesive paper;

- fluorescent and clear polyurethane paint;

- sandpaper.

Choose a "colorful" option or relatively evenly glowing is necessary based on your taste and needs.

To handle a wooden tabletop using a special resin can anyone who knows how to hold the tool in their hands.

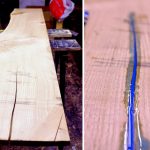

The tree is chosen with noticeable cracks of irregular shape. Welcome board with visible places from the cut of bitches and heterogeneous texture. Good for cypress or oak. If the tree is not dry enough, expose it to the sun for a while.

The tree is chosen with noticeable cracks of irregular shape.

Epoxy need to take enough to fill the cracks several times.

Epoxy need to take enough to fill the cracks several times.

Independent creation of furniture for the cottage or at home is a great help to save the budget.

Required Tools

For furniture decoration will require:

- Sander;

- jigsaw.

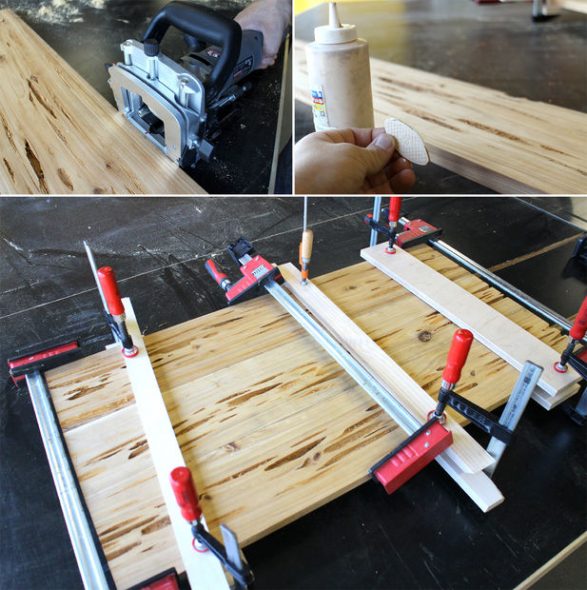

The table is ground both before coating the surface with epoxy and after

The table is ground both before coating the surface with epoxy and after.

Before surface treatment the tabletop should be assembled from two prepared boards.

After some time, with the correct observance of all stages of processing, you will receive a table with a fascinating luminous effect.

Manufacturing process: step by step instructions

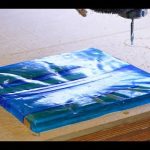

- Before surface treatment the tabletop should be assembled from two prepared boards. By combining them, polish the base.

- Pour the prepared mixture of epoxy resin and luminescent paint onto the table. The composition should fill all cracks, so repeat the procedure 8-10 times. After that, cover the surface with adhesive paper and leave to dry until the next day.

- Sand the finished surface after removing the paper. After stripping, coat the base with polyurethane paint.

- Once again, run the grinding machine on a still wet surface. Remove resin residue. If necessary, the edges can be trimmed and the corners rounded with a jigsaw.

A table with a glowing surface can be arranged to your liking

The final stage - decorating

A table with a glowing surface can be arranged to your liking. Thick wooden board looks great in a simple form (even with visible "defects"), and in combination with carved legs. This can be done using a jigsaw. You can varnish them or use epoxy residues, as well as the countertop, to give a uniform style to the product.

You can varnish or use the remnants of epoxy, as well as the countertop, to give a uniform style to the product.

Glowing table can be made stationary or folding.

After processing it is necessary to polish the furniture with the help of a typewriter.

After processing it is necessary to polish the furniture with the help of a typewriter.

At night, the product will glow irregular divorce, which creates a "magical", festive effect, which in itself is a decor.

At night, the product will glow irregular divorce, which creates a "magical" effect.

Depending on the texture, a part of the resin can be applied - on cracks, or covered with luminescent composition.

At desire of contrast of a support cover the paint which is different in color from the main palette.

Creating a festive effect, which in itself is the decor.

Good for cypress or oak.

VIDEO: Glowing table with their own hands

50 photo ideas: do-it-yourself luminous table

The style of the dining table in the small living room

The style of the dining table in the small living room

How to choose a kitchen table?

How to choose a kitchen table?

Making a folding picnic table with your own hands: drawings, tips

Making a folding picnic table with your own hands: drawings, tips

The mechanism of transformation of the table: the advantages and disadvantages

The mechanism of transformation of the table: the advantages and disadvantages

Sliding table - saving space and a stylish interior solution

Sliding table - saving space and a stylish interior solution

How to make a table from saw cut wood with your own hands.

How to make a table from saw cut wood with your own hands.