How to glue the edge to the tabletop at home.

How to glue the edge to the tabletop at home.

We make a table in the gazebo with their own hands

Handmade things will never go out of style. And this concerns not only jewelry. Garden and indoor furniture hand made is no less popular. This is due to many factors, the most compelling of which is cheapness. We will consider other advantages, disadvantages, and all the nuances of the design on the example of creating a table for a gazebo.

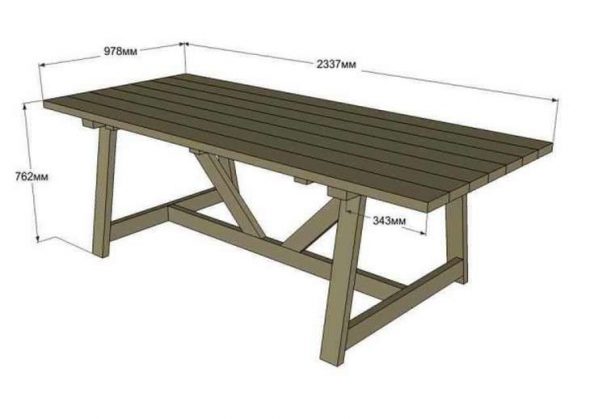

Big and strong table for giving the hands

Content

Advantages and disadvantages

Before the process begins, you may be worried by the question: "Is it worth it?" Is it not easier to order the design, or buy a ready-made one? Perhaps easier, but this is not the best option. And you will see this by reading this article.

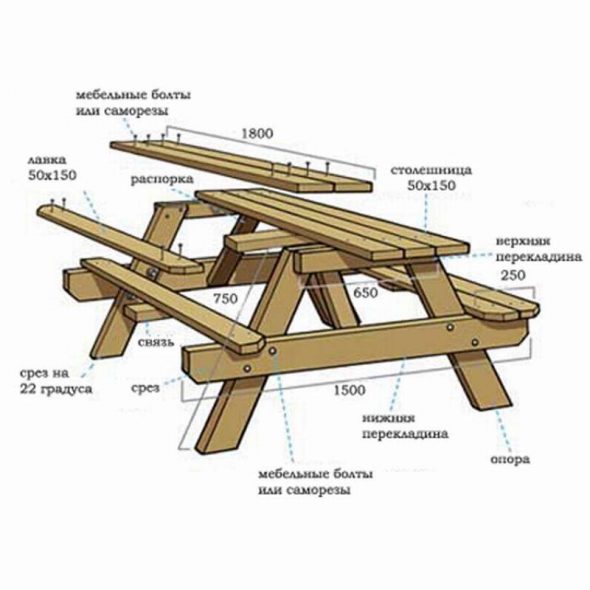

Convenient cottage table with benches that does not require large manufacturing costs

To begin with, the gazebo at the dacha has a significant place. She gathers all relatives and close people, is also the subject of self-expression and pride of the owner. The table here should be solid to fit all the guests, and at the same time it is masterfully executed, better by the owner’s hands, which will indicate his concern for his own house.

Table for an arbor of an unusual form

Making a table in the gazebo with your own hands, you have a few more advantages.

- Cost Of course, making the furniture yourself will be cheaper. After all, you do not have to pay for the services of the master, besides, you can use the available tools, and already existing tools.

- Appearance. It is not always possible to find among the finished goods what is needed in a particular case. Doing everything with your own hands, you already have a complete idea in your head, and you can put it into practice with precision.

- Dimensions. Not less significant factor. In the process of developing a project, you consider all the dimensions of the pavilion and the chairs or lavas. You do not have to go shopping in search of furniture of the right size. It will be enough for you to make the correct drawing.

Another plus is the pleasure of the process. Many owners love to make for their home a variety of objects, which later will be the object of their pride.

A country table with a built-in ice box will help make outdoor recreation on a hot day even more enjoyable.

Speaking of cons, you can only mention a lot of time spent. But you will spend time ordering, traveling around the shops in search of the desired product. Yes, and you can be considered wasted time spent with pleasure?

Choose the type of design

We have already decided: a table for a gazebo with our own hands is a win-win option. So get down to business.

First you need to decide on the type of construction. On this basis, we can distinguish 3 options.

- Folding. Its main advantage is compactness. The peculiarity is that it has folding or twisting legs and a folding tabletop. It is easy to transport or remove for a while.

Folding picnic table

- Transformer. This type of design also has a folding mechanism.It differs from the previous one in that this kind can be transformed into a bench or other furniture. This type is also quite comfortable, but not so durable due to the large number of sliding mechanisms.

A table a transformer with chairs for picnic

- Stationary. Without additional mechanisms and the ability to transform.

A round stationary table for giving will look great on the veranda or in the gazebo

We stopped at the last version as it is the simplest to manufacture and durable to use.

Self-made Stationary Dining Table

Also, products can be divided according to the shape of the tabletop. The most common square. But often there are round. We intend to make a square-shaped table with obtuse angles.

We select the material

No less important factor. Future material must meet the following criteria:

- strength;

- durability;

- reliability;

- ease of processing;

- naturalness

This is the perfect set of qualities. However, in reality, they sometimes have to retreat. So, there are several material options.

- Metal. The easiest to handle for those who are friends with welding. Make metal table is not difficult. It will be really durable and reliable, but has a significant drawback - the appearance. It is cold, both by touch and by sight. Metal furniture can create a somewhat unpleasant atmosphere. However, this option may be interesting, and has the right to exist.

Bench with a table on a metal frame

- Tree. The most common option. Often furniture, like the pavilion, is made of natural wood.

Table and benches for a wood gazebo do it yourself

We will focus on the second option. And in this case, we also have several choices.

- Natural wood. Usually the furniture in the gazebo is made of pine or oak. Pay attention to other wood species, but they must be durable. Natural wood has a special energy, smell and shape, thereby creating a pleasant atmosphere for friendly gatherings.

The best option for making a table in the gazebo with your own hands is hardwood

- Chipboard materials. They are rarely used for garden furniture, as they are not very durable, but are also found in such products. Most often they are used in combination with other raw materials (wood or metal)

Chipboards are afraid of moisture, so they are not suitable for outdoor arbors

We have chosen to work natural wood. Therefore, we consider all the nuances of working with him.

Base processing

Since the outdoor furniture is exposed to different levels of humidity and temperature, not to mention the experience of the winter period, the wood must be treated with special means. This procedure is required. It will help the product to serve for a long time due to the fact that it will prevent the destruction of the base by moisture, temperature changes and insects.

Wood must be treated with protective compounds both before and after work, already in the finished product.

It should be remembered that the processing of wood produced before and after installation. At the end of the design, the finished product is coated 2 times with varnish.

Important! Choose high-quality tools to process the base, even if they are expensive. A cheap chemical will not protect a tree, and harm it.

So, we chose the material for the base and processed it. Now you can proceed to the design of our creation and its decoration.

Step-by-step instruction

The simplest design of the garden table

To do the job qualitatively, and not to miss anything is better to make a plan, and indicate in it all the necessary details. We offer you a step by step plan, which you can take as a basis.

| Stage of work | Tools and materials | Expected Result |

| Creating drawings | Whatman, pencil, ruler, tape measure | Completed project with all calculations |

| Preparatory | All tools (we consider below), a sufficient amount of wood, fasteners | Prepared a basis for further action. |

| Manufacturing of individual parts | Boards, woodworking tools, tape measure, pencil | Made all the components of the future product |

| Assembly | Prepared components, fastening tools | Completed, surface ready for final coating |

| Final cover | Varnish, paint, brushes | Creation can be used |

Now let's go through the details of each item in the plan.

Creating drawings

Drawing a simple wooden table

All work must begin with a plan and project development. At this stage, you can use the help of a professional, or make a drawing yourself. However, it should be remembered that they must be accurate. Any, even small, errors in the calculations can lead to errors in manufacturing.

The scheme of the assembly of the country table of wood

Dimensions are calculated based on the dimensions of the gazebo and lavas. The optimal height is approximately 80 cm. In the drawing, you must specify all components of the future product, dimensions, methods of fastening, and the cost of the project.

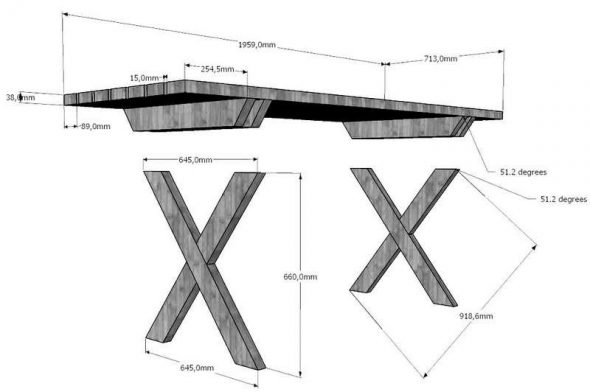

The drawing of the garden table with X-shaped legs

Preparatory stage

To act further, having a drawing, it will be easier. In it, we indicated the necessary number of parts and measurements. Based on these indicators, we select materials and tools.

For the work we need quality wood. We chose a pine board. Also needed screws and metal corners. From the tools we will prepare a saw, a grinding machine, a drill.

The surface is treated with a planer and ground with an electric grinder.

As we see, we need not so many tools and materials, and making a table with our own hands is not difficult.

Manufacturing of individual parts

The direct manufacturing process begins with the processing of individual parts. We have a drawing, which indicates which elements are needed, their number, size and other parameters. So, we need to make:

- countertop,

- rectangular box;

- legs.

To make the tabletop you need to closely place the polished boards and connect them with thin wooden planks.

We assemble a tabletop from polished boards

The legs are cut to the desired shape and size, polished. This is enough to prepare them for assembly.

Let's make a box of the top binding. First, we make a strong rectangular box slightly smaller than the size of the table top (take all measurements from the drawing). To do this, you need to take a strong and thick boards, connect them together butt.

We assemble the table frame, grind everything thoroughly

Next, go to the assembly of parts.

Assembly

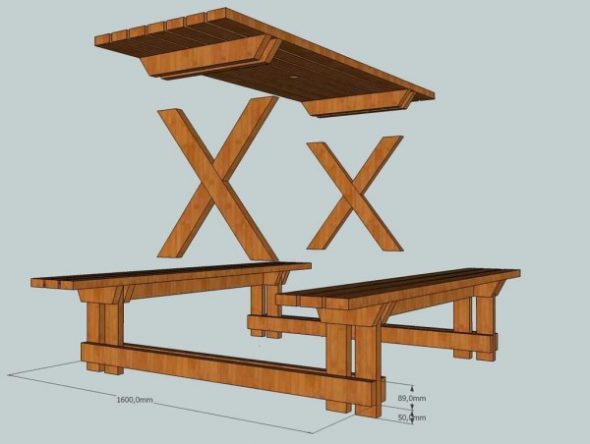

We install legs and jumpers

To the rectangular box fasten legs. To do this, they need to insert into the rectangle into the corners and fix with metal corners and screws.

To make the construction durable, you need to add stiffeners. To do this, prepare boards corresponding in size to the distance between the legs. Attach them to the inside of the legs with screws. For strength across the resulting square, add another bar. Do the same operation with the upper square.

Outdoor table for giving with benches - assembly option

The last touch is the installation of the tabletop. Attach the resulting plane to the box and attach to it with a drill and screws. So we have a solid and simple do-it-yourself gazebo table.

Final cover and design

Next we cover the table with varnish, grind and repeat 1-2 more times.

We are at the finish line. The product is ready, it remains to make the final finish. Before starting work, we treated the wood with special chemicals to prevent its destruction.After installation, it is necessary to carry out another treatment - varnish coating. So the product will last much longer and will be safer to use.

DIY table ready to use

Our creation is ready to use. It can be left in its present form, because natural wood itself is a great decoration for a gazebo.

Another version of a homemade table of boards

You can paint it or paint it and re-open it with varnish. There is another interesting way - burning. But it is made before the coating, and it is better to entrust this work to a professional.

That's how we got a table in the gazebo. As you can see, it is not difficult to design it, and even fun.

A table and benches look original in a two-color version

Video: Do-it-yourself desk

50 beautiful and functional tables made of wood, made by yourself for the gazebo:

How to glue the edge to the tabletop at home.

How to glue the edge to the tabletop at home.

We make a beautiful and strong country table with your own hands

We make a beautiful and strong country table with your own hands

We make a table transformer with your own hands

We make a table transformer with your own hands

Round table do it yourself

Round table do it yourself

We create a table-bench transformer with your own hands

We create a table-bench transformer with your own hands

Why you need to take into account the size of the kitchen table in the interior

Why you need to take into account the size of the kitchen table in the interior