Sliding table - saving space and a stylish interior solution

Sliding table - saving space and a stylish interior solution

Making a table for a sewing machine with your own hands

Nowadays, sewing craftsmanship can be considered not only as the art of creating clothes, interior objects and accessories, but also a way to turn a hobby into a business project. Custom-made items are valued more than stamped in a factory. Of course, every craftswoman dreams of a perfectly organized workplace, which will simplify the creative process and relieve unnecessary inconvenience. A sewing table is a necessary attribute for tailoring, but is it worth spending money on buying ready-made cabinets when you can make a table with your own hands?

Every craftswoman dreams of a perfectly organized workplace, which will simplify the creative process and relieve unnecessary inconvenience.

Proceed to assembling the cabinet cabinets: connect the table top, sidewalls and support strips with self-tapping screws.

There are many options for desks on the market that were designed specifically for tailors, but the costs for the purchase of new furniture do not always justify their cost. And if for sewing new clothes a high level of mastery and practical experience is required, then for the manufacture of a table for a sewing machine does not need to have a special talent. If you know how to handle a tape measure, a screwdriver and a jigsaw, this is an occasion to think and make a table for sewing with your own hands.

A sewing table is a necessary attribute for tailoring.

Content

Why is it profitable to make the furniture yourself?

Many may ask: why waste time on making a sewing table with your own hands, when you can simply buy ready-made? If you carry out a simple calculation, it turns out that most of the cost of the product is the cost of the labor of a stranger and the rental of commercial premises. From this follows the main advantage - saving the family budget. Expenses will be spent only on materials and accessories, which is 3-4 times cheaper than buying a finished table. With the money saved, you can take training courses of creative excellence, which will be a profitable investment.

There are many variations of desktops on the market, designed specifically for tailors.

When installing the tabletop to ensure that the fastening was carried out exactly according to the corresponding drawing marks.

The self-made sewing table becomes not just a unique thing, but also a reliable helper in the creative process. How many things should fit in this small bedside table: sewing accessories, sets of threads of different colors and thickness for each type of fabric, cutting devices, tapes, appliqués and other accessories. At the same time, the size, color, material, construction of the table top and the body will be recreated at the request of the owner himself. Whether the table will be a strict workplace or a real art object is up to you.

If you know how to handle a tape measure, a screwdriver and a jigsaw, this is an occasion to think and make a table for sewing with your own hands.

The modern market is full of furniture made of chipboard, but not everyone is eager to use furniture made from sawdust. In the manufacture of furniture with their own hands, you can choose environmentally friendly materials.The price of the issue is also beyond doubt: the cost of a pine furniture panel will not exceed the cost of the finished table with a folding tabletop. Lacquered wooden furniture does not emit toxic substances and fills the room with a delicate aroma of pine forest. In addition, natural materials are characterized by durability, strength of fasteners and the possibility of restoration.

The main advantage follows: saving the family budget.

Finished product and components varnish.

We determine the design and construction

Depending on the size of the room, the dimensions of sewing equipment and the availability of additional tools for sewing, the following models of sewing tables are distinguished:

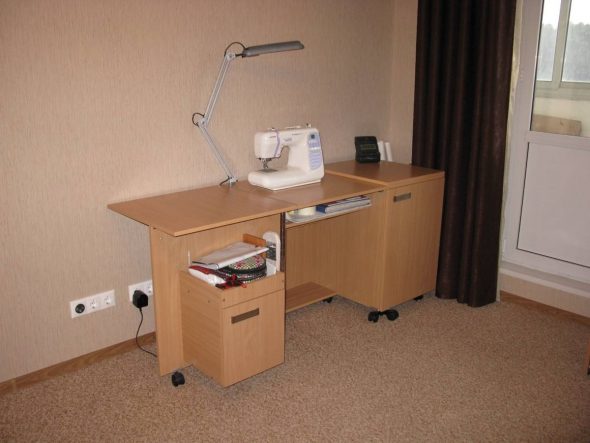

Cabinet with sections for storage. The model is easy to manufacture, but it has a small tabletop area. Suitable for amateur craftsmen.

Expenses will be spent only on materials and accessories, which is 3-4 times cheaper than buying a finished table.

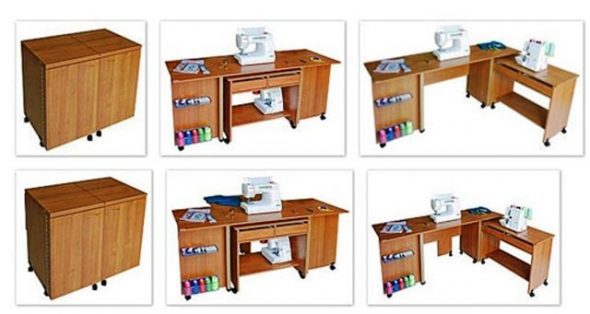

A table-book with a compartment for a sewing machine and storage of accessories. Differs in spaciousness and versatility. Suitable for small spaces.

Drawers allow you to store precious jewelry boxes and accessories, and in a compact state the table does not take up much space.

Assemble the drawers.

Table with drawers and folding table top. A great option that suits you for professional use. Drawers allow you to store precious jewelry boxes and accessories, and in a compact state the table does not take up much space. In addition to the sewing machine on the table at the same time you can put an overlock, without losing in convenience.

The self-made sewing table becomes not just a unique thing, but also a reliable helper in the creative process.

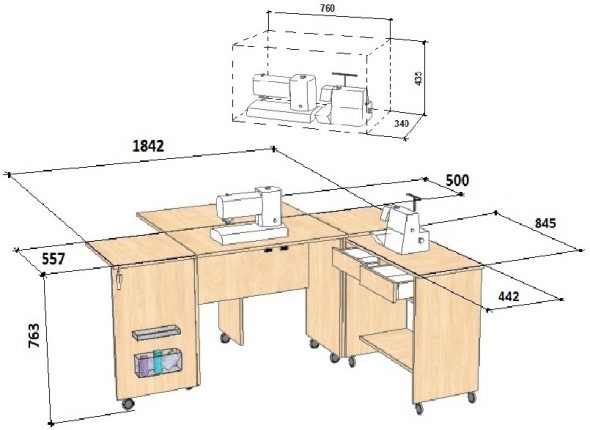

Corner transforming table. Making such a model at home requires a lot of time and professional experience, so not everyone will cope with this task. In the unfolded form, the transforming table takes up a lot of space and is inconvenient in small apartments.

In the unfolded form, the transforming table takes up a lot of space and is inconvenient in small apartments.

Lastly, attach the doors and handles, insert the assembled drawers.

When material matters

It is worth paying special attention to the choice of material: the practical and aesthetic properties of the finished product depend on it. The comparative table shows the key characteristics of various materials.

| Name | Ecological properties | Moisture resistance | Durability |

| Chipboard | Separates formaldehyde, as part of the refined products | low | In such materials, screws and nails tend to loosen, fasteners gradually lose strength |

| Laminated chipboard | Does not emit harmful substances due to coverage | ||

| MDF | Environmentally safe | increased | |

| Plywood | All natural material | High when coated with polyurethane varnish | Retain the strength of fasteners, do not rot when coated with protective compounds, have a long service life |

| Solid wood |

Whether the table will be a strict workplace or a real art object is up to you.

Thus, financial investments in furniture made of natural wood and plywood are suitable for a person who focuses on safety, environmental friendliness and durability of furniture. Investments in natural material are always justified: such a sewing table will delight its owner with the beauty of natural texture and smell, durability and will last more than one generation. If the cost item does not provide for high costs, then from the budget options you can choose laminated chipboard or MDF, they are more advanced and safer materials.

The modern market is full of furniture made of chipboard, but not everyone is eager to use furniture made from sawdust.

The reliability of furniture assembly is determined by high-quality fittings.For a simple folding table with drawers, a shelf for the sewing machine and additional compartments you will need: butterfly loops, screws, ball guides, mounts for the base, legs with adjustable height, a handle with doors or for easy folding of the table top. The latter can be made in a certain style and perform a decorative function.

In addition, natural materials are characterized by durability, strength of fasteners and the possibility of restoration.

Armed with instructions, tools and good mood, you can independently assemble a table that meets all the requirements of the master of sewing craft.

Step-by-step instruction

Before you begin, you need to make sure you have the following tools:

- screwdriver;

- hammer;

- pliers;

- jigsaw;

- set of screwdrivers;

- sandpaper;

- polyurethane varnish for wood;

- brush or roller;

- edging tape (for chipboard, MDF);

- building level;

- construction pencil.

Investment in natural material is always justified.

Step 1. At the first stage it is necessary to choose the drawing of the drawer for the sewing machine and make cutting of all the parts on paper with the indication of dimensions. With the finished drawing you should go to the building materials store. For the manufacture of folding table with drawers will be enough one sheet of chipboard, MDF or plywood.

The reliability of furniture assembly is determined by high-quality fittings.

Step 2. Then you need to mark the details on the shield with a construction pencil with the edge and cut it with an electric jigsaw; mark and make holes for fixings. If natural wood is used, the surface of the parts must be sanded. Paste chipboard and MDF with edging tape. In order not to cut the parts yourself, you can order a cut and edge-cutting according to the drawing and immediately proceed to the assembly stage.

The latter can be made in a certain style and perform a decorative function.

Step 3. Proceed to assembling the cabinet body: join the table top, sidewalls and support strips with self-tapping screws. Attach the back wall with a hammer and nails, making sure that the wall edges do not protrude from the sides. Using self-tapping screws, attach the legs to the cabinet, check the result with a building level. If there are deviations from the horizon - correct. When installing the tabletop to ensure that the fastening was carried out exactly according to the corresponding drawing marks.

At the first stage, it is necessary to choose the drawing of the drawer for the sewing machine and make cutting of all the parts on paper with the indication of the dimensions.

Step 4. Finished product and components varnished. Cleaning of the tabletop should be taken with special care, as it will become the main working surface. If the varnish coating will be made in several layers, it is necessary to withstand the time between application. The varnish will dry completely after 36 hours.

For the manufacture of folding table with drawers will be enough one sheet of chipboard, MDF or plywood.

Step 5. Assemble the drawers. After varnishing, attach the ball guides. Check if the drawers are evenly inserted into the fixtures by setting the building level to the bottom of the drawer.

If natural wood is used, the surface of the parts must be sanded. Paste chipboard and MDF with edging tape.

Step 6. Lastly, attach the doors and handles, insert the assembled drawers.

A table for a sewing machine is an indispensable tool in the process of translating creative ideas, but in furniture stores it is not always possible to find an option that suits you. Armed with instructions, tools and good mood, you can independently assemble a table that meets all the requirements of the master of sewing craft.

Cabinet with sections for storage.

VIDEO: Stand for sewing machine

Sliding table - saving space and a stylish interior solution

Sliding table - saving space and a stylish interior solution

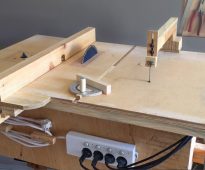

Table for circular saw with their own hands. Drawings, photos, tips.

Table for circular saw with their own hands. Drawings, photos, tips.

How to use unusual tables in the interior

How to use unusual tables in the interior

Basic parameters for the selection of a table-transformer

Basic parameters for the selection of a table-transformer

We make a manicure table with your own hands

We make a manicure table with your own hands

Choosing a table for makeup with a mirror

Choosing a table for makeup with a mirror

Good evening. Is it possible to purchase a lifting mechanism for a sewing machine from you? I want to make a table to lower the sewing machine down when I don’t use it