Choose the design of kitchen set: technical equipment and facade

Choose the design of kitchen set: technical equipment and facade

How to make a DIY do-it-yourself buffet

Wood is a wonderful material for making furniture: durable, aesthetic and durable. The products made from it are elegant and practical, and if they are made by hand, it will be especially pleasant and loved, as the home artist puts his love for home and family into the work.

The kitchen is one of the most significant premises in the home of any family.

If your kitchen is small, then you can make a narrow piece of furniture.

Content

The advantages of creating your own hands

If the house master is "friends" with carpentry tools, it will not be difficult for him to deliver a pleasant hostess and make a buffet with his own hands, which is necessary in any kitchen.

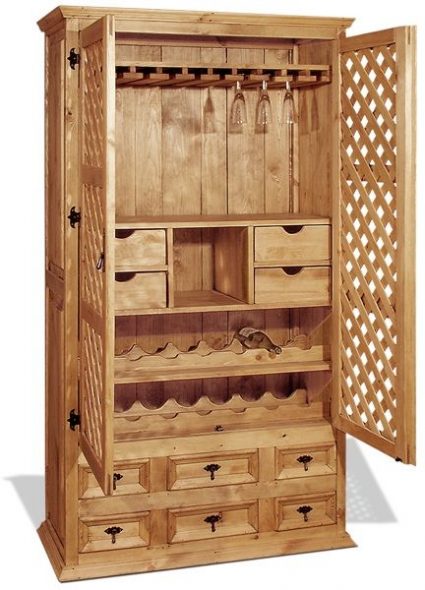

For maximum convenience and comfort, you should equip it with not only beautiful, but also functional furniture, such as, for example, a buffet.

An excellent solution for any home is the installation of a corner kitchen cabinet.

A self-made kitchen cupboard has a number of advantages over its “shop brothers”:

- for it, you can choose a unique design;

- choose the material to your liking;

- use original fittings;

- choose the color palette of the buffet, the most well suited to the kitchen interior.

To make the interior original, you can make it yourself, putting your soul into the work, using any materials.

The most important nuance when installing such a cabinet is the calculation of the trajectory of the door opening movement.

In addition, wood products are extremely beneficial to health: they do not contain toxic compounds in their composition and do not emit harmful substances, but they fill the room with aromas of essential oils.

Sideboards and cupboards for the kitchen do not have big differences and look very similar to each other, because the progenitor of both is the wardrobe.

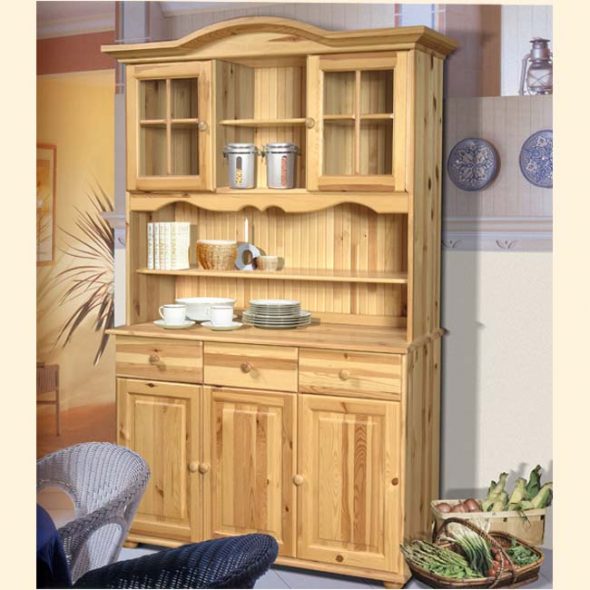

The kitchen buffet is an excellent solution for the kitchen interior.

Wooden sideboard - durable and comfortable. It will last for decades, it is easy to restore and repair.

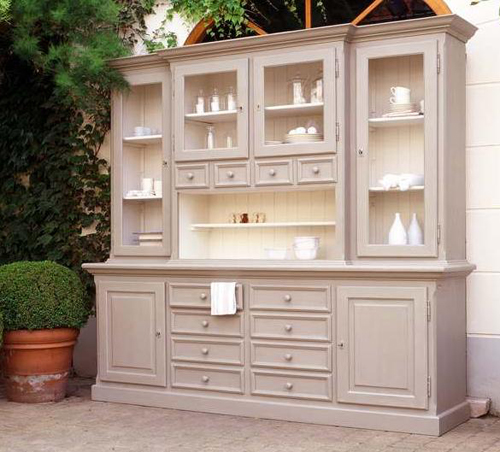

A natural wood buffet will look rich and elegant, but at the same time it will cost a lot more.

Another important advantage of making a kitchen cabinet with your own hands is the ability to make it in the original configuration and dimensions that most fully meet the convenience and comfort.

To get a beautiful product and not spend too much, you can make the body of the furniture from cheaper raw materials, such as chipboard, and the facades from more expensive and beautiful.

We determine the design and construction

Independent production of a kitchen cupboard opens up a wide field for the home craftsman’s fantasy. He can do it, in accordance with his visions and ideas, in various styles:

- retro;

- high tech;

- art;

- minimalism and others.

Modern kitchen buffets can be made based on a step-by-step description of this process.

The design of cabinets can also be very diverse, including corner and round.

All products made by themselves emit the comfort and warmth with which it was made.

Necessary materials

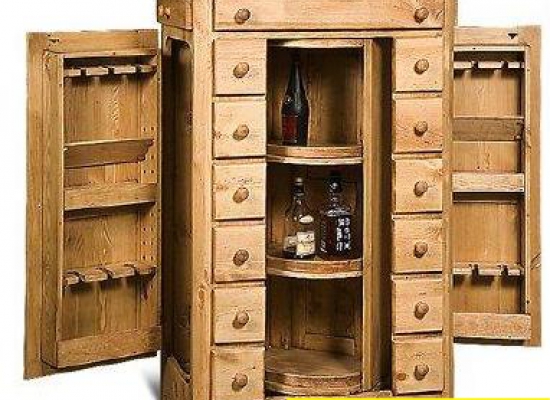

In a friendly family of kitchen furniture, the buffet occupies a special place - it reigns in the kitchen and bears in itself the features of an elegant sideboard and a regular cupboard for dishes. Previously, furniture was made “for centuries”, therefore, for its manufacturing, we chose the most durable and high-quality wood, well seasoned and processed.

This version of the furniture is practical, beautiful and takes up little space.

Today's offer of building materials allows you to choose the option you want to make a buffet with your own hands. But one of the most popular foundations for kitchen furniture is steel MDF, fiberboard, chipboard and solid wood. The latter does not require additional characteristics, differing in strength, durability, beauty. As for the wood boards, each of them has its own effective properties and disadvantages.

- Fiberboard is resistant to moisture and temperature changes. It is light, strong, durable, affordable and not difficult to handle. Buffet of such material can be quickly assembled. It can be made functional and visually appealing. Most often, these plates are used to install the rear walls of wall cabinets, drawers and shelves.

- Chipboard is presented in a variety of colors. This is a durable and inexpensive material from which you can make a comfortable spacious and original cabinet that is easy to fit into any kitchen interior. Among the significant drawbacks are emissions of formaldehyde into the air. To reduce their harmful effects on human health, it is necessary to place furniture made of chipboard, away from heat sources.

- MDF is widely used today. It is made according to modern technologies, therefore it is an environmentally friendly material. It has high moisture resistance, which increases the feasibility of its use in the kitchen. It has a soft, easily processed structure that allows you to make from it a variety of decor for furniture fronts buffets, give the products a variety of shapes. The only drawback is considered to be a fairly high price, compared to the cost of chipboard.

- Wood is a special chic and demonstration of high taste. Environmentally friendly, natural material.

This means that you will simultaneously receive moral pleasure from the work done, even if it seems to you to be somewhat laborious.

For the manufacture of buffets most often used the following tree species:

- pine, durable and easy to handle;

- larch, strong and not subject to the ravages of moisture;

- oak, almost eternal, not rotting and does not require treatment with varnish.

Kitchen cabinets can appreciate only true connoisseurs of beauty and art.

Depending on the place where the do-it-yourself cupboard will be installed, you can use different materials. To the cottage or summer kitchen, you can make a kitchen cupboard of plastic, simple in design and inexpensive.

After all, with the help of this product you can restore order in this part of the house, and it will become the “highlight” of the interior.

The original buffet in the mansion’s kitchen, made of MDF or solid wood, with unusual shelves and niches, will look expensive and presentable.

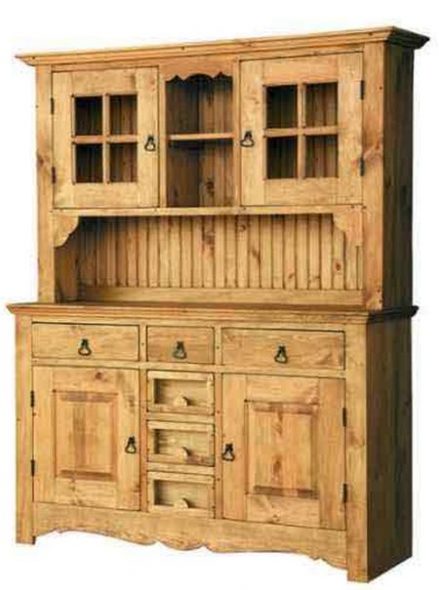

To date, the buffet is a kitchen cabinet, which is completely closed at the bottom, and its upper part is made in the form of a shop window.

Required Tools

To make a buffet for the kitchen to your liking, you need an individual set of tools, but among them there are those without which you can not do, no matter what material, design and configuration of the product the master chooses.

In the classic version there are work surfaces. This part is always decorated with decorative elements.

Standard set:

- drill;

- wood drills;

- jigsaw;

- a circular saw;

- Sander;

- screwdriver

and other tools and devices that should be at hand.

The most common are closed-type cabinets.

Manufacturing process: step by step instructions

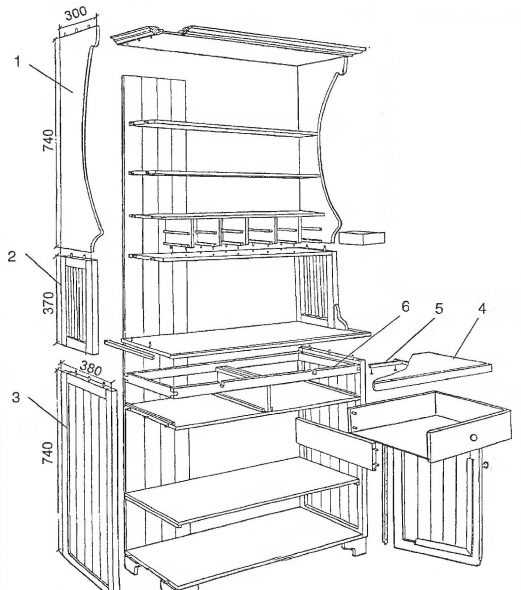

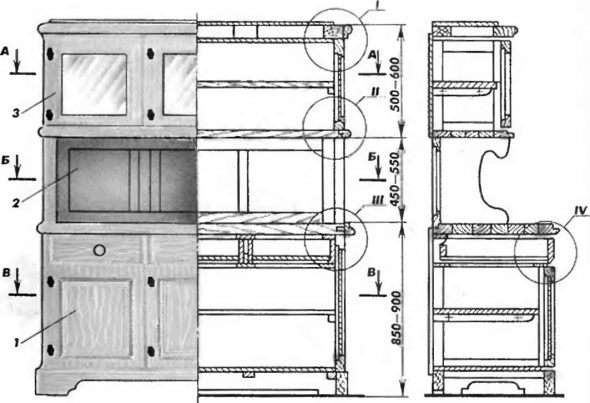

Before you take up the tools, you need to clearly understand what kind of coffee shop you will be doing, and reflect your thoughts and ideas on the drawing, indicating all the details of the product.

Buffet is a piece of furniture for the kitchen.

First, the largest elements of the product, which form its basis, are prepared according to the available drawings, taking into account the necessary parameters. In order not to disturb the order of assembly and not to lose the necessary parts, home craftsmen with experience advise all parts to be numbered.

It has the form of an ordinary cabinet with a closed and open part.

After finishing the preparatory work, the cabinet is assembled in the following order.

- Preparation of side parts of furniture, drilling holes in them. It is worth paying attention to the advice of experienced craftsmen recommending the use of the depth stop to control the distance between the grooves. Its use allows you to protect furniture parts from through drilling.

- Buffet Partitioning

- Connection of the upper part of the product and the outer side parts. The top of the product is located on the end mounts, and the sides and bottom are pushed to the stop.

- Installation of internal parts. First, the body of the buffet is mounted on the rear ends. Screws are used to fasten the lower part, and the fixing angles are used to connect it to the upper part.

- Assembly of basement parts and their mounting. To mark the plinth, a drawing of kitchen furniture is used, according to which the panels are fixed on the bars located at the corners of the structure.

- Registration of front part. The slab is placed in its place, and the sides are left with projections of the required size. They are needed for hanging the doors and fixing the back panel.

- Fixing the back wall. Buffet body is laid out on its side to secure the canvas in the desired position.

- Installation of doors and hinges. Labels mark the left and right doors, bottom and top, after which the hinges are set on the marked marks. Cabinet doors are mounted on their seats, securely fastened to the hinges.

- Installing furniture in its permanent place, installing shelves and drawers, checking the quality of installation and ease of use of the product.

The designs of such cabinets are different.

However, in other designs you can find kitchen furniture with engraving, plinths and curtain rods on the facades.

Buffet decoration

The final stage in the manufacture of a unique, custom-made kitchen cabinet will be its decoration. Here can be used:

- ready accessories;

- wooden or metal decor products, made by hand;

- ornaments and color decoupage images;

- photographs, decorations of glass and plastic;

- original decor products, custom-made or custom-made, depending on the style of the product.

To assemble the furniture you need a lot of space, so before you make a cupboard with your own hands, you need to take care of the free space.

Due to the elements of decor and the use of natural materials, most often cabinets are used in the classical style.

VIDEO: # BUFFET Themselves. H. 1

50 photo ideas how to do it yourself with wood

Choose the design of kitchen set: technical equipment and facade

Choose the design of kitchen set: technical equipment and facade

Install the dishwasher into the cabinet (45 cm)

Install the dishwasher into the cabinet (45 cm)

How to cut a hole under the sink in the countertop?

How to cut a hole under the sink in the countertop?

Kitchen without top cabinets

Kitchen without top cabinets

What material is better to choose a kitchen?

What material is better to choose a kitchen?

Choosing a cabinet for built-in oven

Choosing a cabinet for built-in oven