Easy chair do it yourself

Easy chair do it yourself

How to make a chair-bed with your own hands

Using the chair-bed instead of full individual items of furniture relevant for small spaces. The successful combination of seating and sleeping allows ergonomically organize the space of the room.

The search for options for arranging the space of a small apartment often leads to the idea of buying a folding chair.

Buying such a thing may be unprofitable. But you can make your own furniture, if you have the skill. How to make a chair bed, they know many who equip their apartments and houses with hand-made objects.

Content

The advantages of creating your own hands

Advantages in self-production of furniture - lots of. First, the main materials, which are used, can be found at home or in the country, and also buy in specialized stores at a price incomparably lower than the finished thing.

Billets made of wood or its derivatives, filler and fabric - this is what you need, not counting the different types of fasteners.

To make a chair bed do it yourself, you will spend 2-3 times less money. In addition, you can choose your own design. constructions, coating material and color range.

All this allows you to create an original model that is convenient for your home.

We determine the design and construction

Chairs-beds are divided into two main types:

- Frame;

- Frameless.

Intraspecific differences of furniture vary based on the choice of form and transformation mechanism.

Traditional performance materials make it a reliable help for many years.

It is more difficult to make a frame model. Furniture with a rigid base is complemented by a layout mechanism that needs to be done correctly so that the “liner” is easily removed and straightened without distortions. The design with two folding legs is easier to make than with four.

You can pick up a wooden base supports, and metal.

It is necessary to determine this or that suitable construction not only on the basis of the complexity of creation, but also of its style, safety and convenience for rest.For folding chair You can choose such materialslike chipboard, plywood, the cloth a certain density, foam rubber for upholstery, if it is assumed frame option.

This furniture is compact and ergonomic, its dimensions are noticeably smaller than a standard bed, but not inferior to it in terms of ease of rest.

A product without a rigid base may have a streamlined shape, moreover it is lighter in weight.

Whatever designs you choose, they must be durable and safe.

Do not forget about convenience - the body should be comfortable while sleeping or relaxing during the day.Remember that the base should be wide enough - not less than 60 cm, otherwise the sleeper will not turn around on the bed.

Today there are many varieties of this furniture. All of them find their place in the interior of the apartment.

Necessary materials

For the manufacture of frame model, you will need the following materials:

- DSP;

- Hardboard;

- Wooden bars;

- Plywood;

- Foam rubber;

- Self-tapping screws;

- Hinges;

- PVA glue;

- Sandpaper;

- Upholstery fabric.

We will make a simple but comfortable thing in life that will be strong and reliable to withstand any unexpected guest.

In building constructions I can apply others materials. For upholstery is better to choose a special the clothDensity and cleanability.

For frameless of furniture are used:

- Case cover;

- Foam rubber;

- Durable thread.

For upholstery will need high-quality foam.

Required Tools

To conceived subject of furniture do right and firmly, you will need:

- Long ruler or tape measure;

- A simple pencil;

- Staples and construction stapler;

- Scissors;

- Hacksaw;

- Screwdriver;

- Sewing machine (for the manufacture of frameless chair).

Tools for work.

If in constructions decor is provided (for example, in the form of applications), then a stencil cut from a dense file folder is useful.

Manufacturing process: step by step instructions

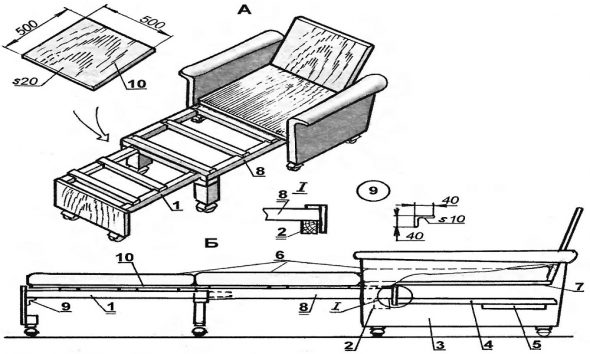

Before starting work, it is imperative to carry out a drawing of the product, where the exact dimensions will be indicated and the parts of the model will be drawn in detail.

Product drawing.

For the manufacture of folding chair frame type you need a lot of space. Choose a spacious room.

First we make the body:

- Measure sheets of chipboard, fiberboard and plywood. The first will go to the sides, back and bottom. Plywood - for folding part.

Saw off excess on the planned lines.

- Connect the side parts (they are also supporting) with the bottom and back using self-tapping screws.

All parts are connected with screws and well glue.

Then proceed to the creation of folding parts. Make 2 frames from the bars along the width and length of the seat. Attach sheets of plywood to them.

Connect the frames with long loops.

To make the chair fold out smoothly, use a metal transformation mechanism — attach steel contours with through hinges on the sides.

The main thing is to make the chair bed yourself so that the parts put together make up a beautiful and even square.

Such a cute armchair can be painted, coated with varnish or upholstered with foam rubber and stylish beautiful fabric.

The next step will be trim:

- Glue the cut pieces of foam rubber with a height of 2-3 cm to the top of the frame.

- Impose exactly the cloth and using a stapler, attach it to the parallel bars at the bottom.

- The sides can also be upholstered using a thin layer of foam rubber.

For the folding design will need legs.

They are made in the middle and front of the frame, flush with the bottom point of the bottom or slightly higher. For armrests, use sandpaper stripped wide boards.

The seat is easy to fold, not clinging to the sidewalls, and just as quickly turns into a chair.

Frameless model is much easier to manufacture. It requires foam, which can be used in 2-3 layers, and thick fabric like a “rain cover” (or less slippery). The cut material is stitched from several sides. the remaining opening is designed to be placed inside the foam rubber.

In order to prepare a chair-bed for sleeping, you should unbutton the straps, then pull the upper pillow towards you.

Equip the length of the segment "lightning." For a more practical use of a frameless sample, make an outer cover.

Since it lacks a rigid base, the back should be placed against the wall.

Decorating a chair bed

In order to give the finished product a stylish and original look, use fantasy.

Design created things can be improved through the use of interesting prints, applications.

From the fabrics used for decoration, look good tapestries. If you want to make the upholstery softer to the touch, choose materials with a nap like artificial velvet.

Such material, moreover, is stronger and more durable.

It is better to sew appliques before the upholstery process.So that they are neat, prepare in advance stencils and shreds of different colors, matched to the tone or contrasting with the main gamut.

At the frame-type folding chair, the front legs, which not all models retract, can be made carved or metal.

To prevent the surface from gathering dust and rubbing, use a cape or sew a special case. Suitable and carpet of the appropriate size, and faux fur - this will make seating in a chair more comfortable, cozy. Another option - sewing removable covers from a light canvas.

This will facilitate the care of upholstery.

VIDEO: Armchair bed do it yourself.

Chair-bed in the interior - 50 photo ideas:

Easy chair do it yourself

Easy chair do it yourself

How to repair a computer chair with your own hands

How to repair a computer chair with your own hands

How to pull the chair with your hands

How to pull the chair with your hands

Chair bed with orthopedic mattress

Chair bed with orthopedic mattress

Chair bag do it yourself

Chair bag do it yourself

Step-by-step manufacture of hanging chairs do it yourself

Step-by-step manufacture of hanging chairs do it yourself