Cat scratched the sofa: measures to save leather furniture

Cat scratched the sofa: measures to save leather furniture

Furniture conductor - what is it and how does it work?

Collecting furniture, the master has to perform the same markup with equal indentation. This procedure is painstaking and takes a lot of time from a specialist. To facilitate the implementation process will help the conductor.

A hole drill jig ensures precision in making furniture

This is a device that helps to produce the necessary markings or drilling holes for confirmat for furniture fasteners. This device makes drilling or marking operations simple, saving time for furniture makers.

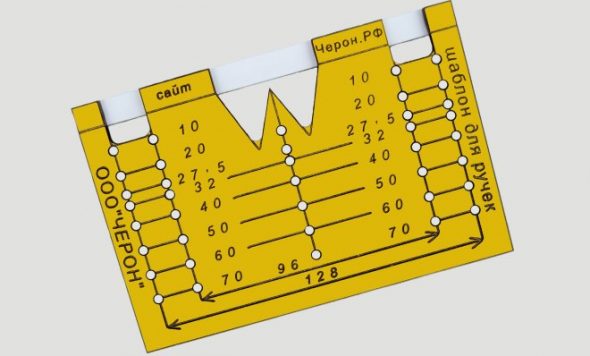

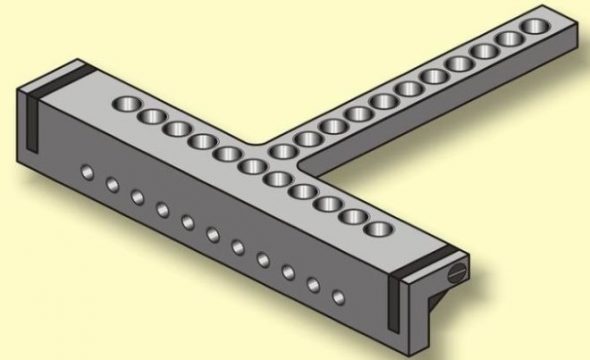

The furniture pattern is a bar with holes, sleeves, a different distance between them, the diameter of the holes is also different.

Using the conductor when drilling the end of the furniture plates will protect you from accidental care of the drill to the side and damage the workpiece.

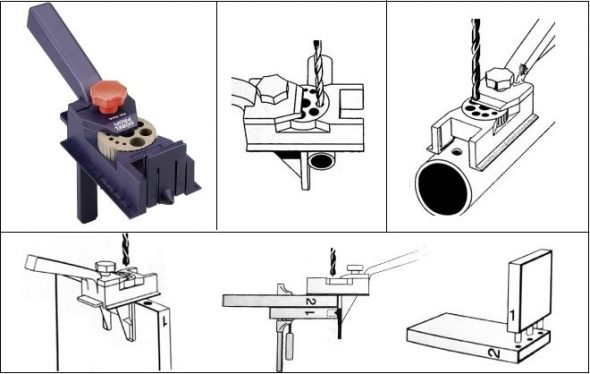

With the help of the instrument, through and closed holes are created for fasteners of furniture fittings. With the help of such a device, the drill passes in the plates at a right angle are obtained. The device is made up of several bushings in one case or in the form of a holder with varying nozzles.

A conductor for making holes in the tubes will be a very useful fixture for a home workshop.

Content

Types of conductors for furniture

The jig for oblique holes is indispensable when making hidden connections of panels and boards

For convenience, accurate marking and drilling of holes in furniture products, various types of devices are used.

- Overhead - templates are superimposed on the DSP and are connected.

Overhead conductors impose on the selected workpiece, fix or leave without clamping

- Rotary - used for the formation of holes in the products of a cylindrical configuration. The device is equipped with a vertical and horizontal pivot axis, making it possible to install the drill at different angles.

This type of conductors has several axes of rotation: vertical, horizontal, inclined

- Universal - templates are endowed with functions of quick reconfiguration of the tool. Used devices for confirmatics.

Universal conductors are easy to changeover, which is important for small-scale production.

- Tiltable - used to perform the process in different planes.

Tiltable conductors need, if necessary, to create for one installation several holes located in different planes

- Sliding and docking - templates that do not require fastening. The tool is applied to the place where the drill will enter.

- Fastened - a convenient tool, but limiting the free actions of the furniture maker.

All types of tools are made in different lengths and diameters, with different pitch holes.

A significant advantage of using the guide template for furniture products is that the holes are coaxial

For the manufacture of furniture conductors under the confirmee, stainless steel is used, differing in technical characteristics:

- resistance to different conditions;

- durability;

- environmental safety;

- resistant to high temperature.

Universal drilling conductor, which allows you to do any furniture with your own hands without effort and special knowledge

Furniture conductor for confirmator is constructed of wood and high-quality stainless steel, which prolongs the life of the device. Products from plastic and organic glass abound in the market of furniture products.

Angle jig for drilling holes at an angle to the plane

Advantages and disadvantages of the furniture conductor

Even a simple fixture in the form of a bar with an emphasis makes it much easier and faster to make one-type holes.

Furniture jigs have a number of advantages.

- With the help of templates, precise oblique and direct drilling under the confirmatte occurs.

- The use of the tool does not require a previous calculation and the application of points under the drill, which facilitates the assembly of furniture.

- With furniture fixture products are going faster.

- You can drill several holes at once, without making markup.

In-right jig with a turret is suitable for drilling standard holes for dowels of any size.

Among the drawbacks of the furniture conductor, only one is noted - the expensive price for a joinery tool. Therefore, many professional carpenters make the conductors for the assembly of furniture with their own hands.

Furniture conductor (minifix) assembly scheme

How to choose the right furniture conductor

The marking jig Assistant is a multifunctional jigging device that, when using the corresponding sleeves, can be used not only for marking, but also for adding holes

The device for the assembly of furniture products greatly facilitates the workflow of professional craftsmen and allows you to make accurate markings for drill holes. Every specialist prefers to purchase high-quality equipment.

Dubel-Profi conductor is an inexpensive but functional device for home use, complete with various accessories that simplify many operations.

How to choose a furniture conductor for furniture assembly.

- Think about what kind of tool you need to do the job.

- Carefully inspect the purchased product and examine the labeling.

- Choose products made from quality material. For example, stainless steel.

- Give preference to tools made by proven global manufacturers.

Condor conductor allows you to drill perpendicular holes of the desired diameter by selecting the distance between them and changing the sleeves included in the kit

Choosing a reliable device, furniture makers will be able to work much faster, which is important in the modern world.

This universal jig is designed for drilling holes for minifix, confirmat, rafix and door hinge.

The process of self-manufacturing conductors for drilling

Most professional craftsmen prefer to produce a furniture jig to drill the holes with their own hands, saving a lot of money to buy a factory appliance. To create a device, a specialist will need:

- electric drill;

- locksmith set;

- Bulgarian for metal;

- welding equipment;

- the material that is needed for the manufacture of the device (rebar, bushings, etc.).

If there is material for the planned furniture unit, the workflow begins.

Drawing homemade conductor for drilling holes for confirmatics

In order to make a furniture conductor with your own hands, precise, meticulously designed drawings of the desired tool with the desired dimensions are prepared in advance. Correctly make a sketch will help the template conductor, a sample of which is on the Internet or from the masters involved in the repair of furniture.When making a tool template, it is worth re-checking the marking accuracy several times to get a quality product.

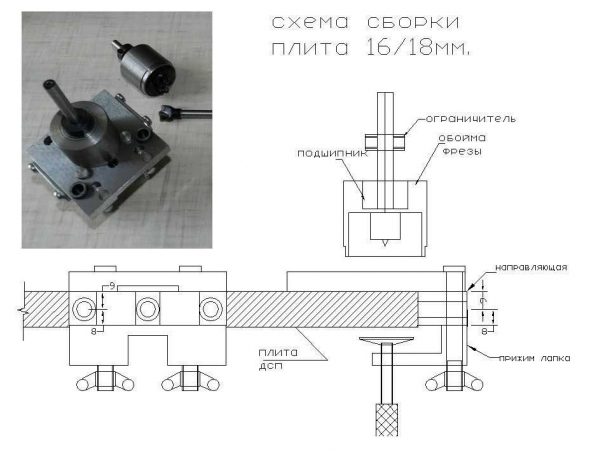

In the manufacture of the conductor will require perfectly accurate drilling of the guide holes and hardening of the finished device

Having prepared a tool template for making holes, the following steps are taken.

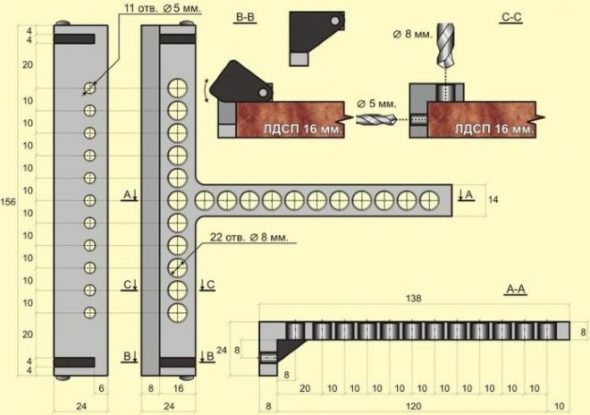

- The grinder or hacksaw cuts the reinforcing bar into pieces.

We take square reinforcement, cut off a piece of the required length and clean it with emery paper, make template holes

- The holes are drilled 8 millimeters from the edge of the tool, focusing on the location of the central part of the plate in which the hole is formed.

- A distance of 32 mm between markings under the drill is performed, the diameter of the holes is 5 mm.

- For ease of use homemade device added emphasis. To make it you need one millimeter plate of metal, 25 mm wide, bending at a right angle. The finished part is installed on the manufactured fixture.

For the manufacture of the stop is used a metal plate, which is bent at an angle of 90 degrees and, together with a piece of prepared reinforcement, is fixed in the clamp

- Structural elements are fixed with a clamp and connected by fasteners.

Cut the thread and connect the two parts into one design

When creating a device for holes, metal bushings are installed, which makes the device reliable. Steel bushings may be in automotive workshops.

Ready conductor with pivoting stops

By purchasing or creating a conductor for furniture with their own hands, highly qualified specialists increase the speed and accuracy of holes when assembling furniture products, thus freeing up time for other important events. With the conductor device masters work efficiently and quickly.

Video: Furniture Jigs and Patterns

Cat scratched the sofa: measures to save leather furniture

Cat scratched the sofa: measures to save leather furniture

How to drag a computer chair with their own hands.

How to drag a computer chair with their own hands.

How to wash the fat from the kitchen furniture?

How to wash the fat from the kitchen furniture?

Faux leather for furniture. What it is?

Faux leather for furniture. What it is?

The combination of colors of the floor and ceiling in the interior. Table and photo

The combination of colors of the floor and ceiling in the interior. Table and photo