Making a highchair with your own hands: drawings, sizes, diagrams

Making a highchair with your own hands: drawings, sizes, diagrams

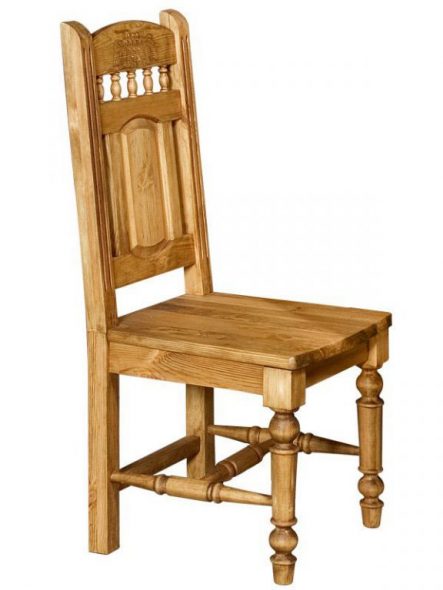

From the stool to the transformer chair - learn to make chairs with your own hands

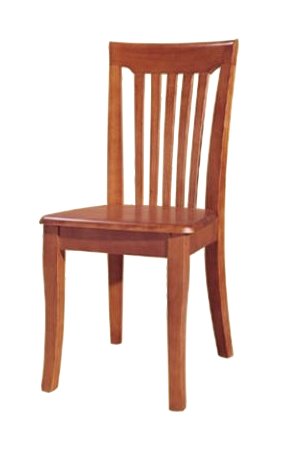

Making your own furniture is not only a great way to save your family budget. With the help of various parts and improvised tools any person can make various designs of wooden chairs. Such work can be done even by novice masters and those who have never considered themselves artisans. The main thing is to be patient and gain endurance. Design does not tolerate fuss and frivolous attitude.

With the help of various parts and improvised tools any person can make various designs of wooden chairs.

Content

- 1 How to make a chair out of wood with your own hands

- 2 The advantages of making chairs do it yourself

- 3 Choosing a chair model

- 4 How to start a newbie

- 5 Wooden chair by professional hands

- 6 We decorate the finished product

- 7 VIDEO: How to make a wooden chair. Do-it-yourself furniture # 2

- 8 50 photo ideas how to make a wooden chair with your own hands

How to make a chair out of wood with your own hands

For the manufacture of chairs of various designs, you must have one main element - the desire. The remaining factors go as an application.

Design does not tolerate fuss and frivolous attitude.

Making your own furniture is not only a great way to save your family budget.

Before starting work, you must answer the following questions.

- Skill level This is the most important point, it depends on him which model of chair should be chosen. If a person has never before made furniture with his own hands, then one should begin with the simplest elements and structures.

- What materials will be made chair.

- Model construction.

- Number of chairs.

- Necessary tools for manufacturing.

For the manufacture of chairs of various designs, you must have one main element - the desire.

Before you cut the first part, you should evaluate all the materials and tools are available.

Before you cut the first part, you should evaluate all the materials and tools are available.

The selection of the heels is determined by the design of the chair and its weight.

The advantages of making chairs do it yourself

Maybe it's better to buy your favorite model and not complicate your life?

Critical minds will ask - is it worth it at all to take it? Maybe it's better to buy your favorite model and not complicate your life? We will understand the pros and cons of this work.

Of the significant drawbacks in the manufacture of chairs can only be noted the need for free time for hiking for materials and assembling structures.

It is recommended to provide home chairs with furniture sockets that protect the surface of the floor covering.

Making a chair with your own hands allows you to:

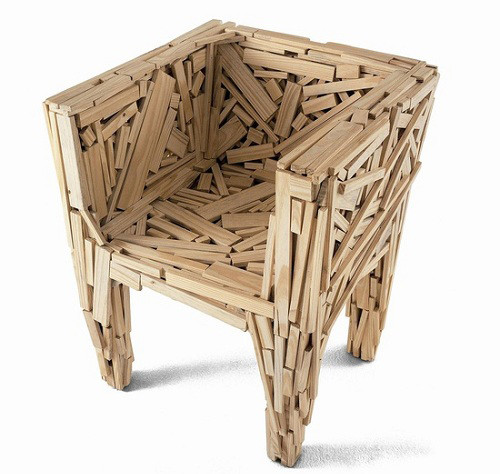

- make a model according to exclusive drawings;

- save money;

- achieve the necessary strength and durability;

- expand the number of their skills and abilities;

- to bring individuality to your interior.

The most important aspect in the manufacture of chairs is it.

You can also use eco-leather or even oilcloth.

Of the significant drawbacks in the manufacture of chairs can only be noted the need for free time for hiking for materials and assembling structures.

How long will it take to make and what will be the final destination of the furniture item made.

Choosing a chair model

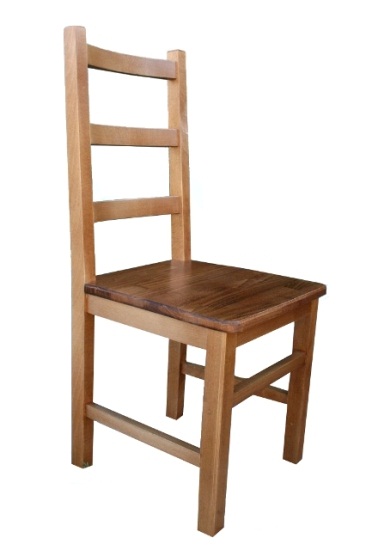

The most important aspect in the manufacture of chairs is its model. It is the model of the chair that dictates the necessary materials for cutting out the seats, backs, hollows, legs and crossbars. From the model depends on what tools the master will need to work. How long will it take to make and what will be the final destination of the furniture item made.

Further work of the master depends on each separate item, and especially on their totality.

Seat furniture items can be of the following types.

- Folding or ordinary.

- Transform into other items.

- Have two or more legs.

- Made from bars, planks or sheets.

- Have back and side armrests.

- Target one or several people at a time.

The newcomer asks immediately the question - how to make a chair with your own hands and where to start?

Further work of the master depends on each separate item, and especially on their totality.

For the functionality of the further operation we process all surfaces and edges with emery paper.

How to start a newbie

The newcomer asks immediately the question - how to make a chair with your own hands and where to start? We offer step by step instructions for making the simplest models for sitting - a chair without a back in the classic version.

The work is completed by coating the product with stain, varnish or paint.

For the manufacture of the chair will need to perform the following steps.

- Prepare the necessary materials. For a piece of plywood or chipboard size 30x30. The seat can also be made by gluing the boards and giving them the desired configuration. Parts of the legs can be classic - from four bars of the same size and 40 cm in height, or two sheets of plywood or chipboard size of 30x40 cm. The crossbar, the fixing legs can be made of bars, boards or plywood trim.

- Do not forget about other parts - screws, corners, tape for processing edges.

- For the manufacture of such a chair will need only jigsaw and sandpaper. The presence of a screwdriver will facilitate the task, but its absence still allows you to assemble a chair with a primitive screwdriver.

- We make a template of parts, first on cardboard and then on wood. Cut the seat, legs, side rails on the specified dimensions, the required length.

- We connect the legs together with the help of front and side rails.

- The final touch is fixing the seat.

Perfectly polished elements will allow to pay minimum attention to the decorative decoration of the chair and give the opportunity to leave it in pristine beauty.

For the functionality of the further operation we process all surfaces and edges with emery paper. Wood should be treated with stain and varnish or covered with paint. Here's how to make a wood chair with your own hands for a beginner.

For aesthetic completeness of the chair, its pleasant appearance, as well as for ease of use, it is recommended to round off all the bars.

Wooden chair by professional hands

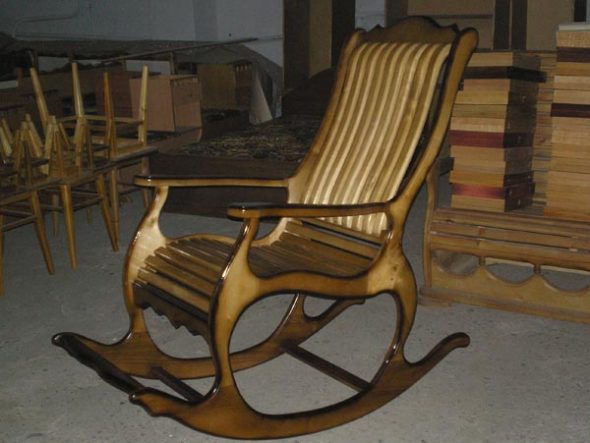

A professional master does not wonder how to make a chair with his own hands. He is much more interesting to make an unusual design that combines several complex elements.

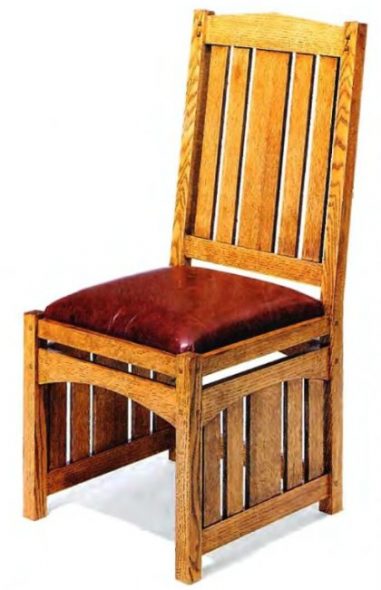

For the decoration of the backs and seats usually take foam rubber and various fabrics or leatherette.

In the arsenal of the pros, there must necessarily be both the simplest devices and professional tools.

Seat furniture can be decorated with soft materials that can be removable or fixed directly on it.

For the manufacture of a folding chair or chairs with backs and armrests you will need:

- pencil;

- roulette;

- glue;

- bar for tsargi;

- boards for the manufacture of seats, backs and rear and side rails;

- self-tapping screws;

- metal corners;

- jigsaw;

- drill for holes;

- Sander;

- manual mill for cutting grooves and spikes;

- screwdriver;

- clamp.

The best decor is an accentuated natural pattern of the wood from which the chair is made.

Consider step by step instructions on how to make a folding chair so that it can be easily transported and used in any conditions.

- We take 4 legs, size 40x25x500 mm. Fasten them in pairs crosswise. Mounts are fixed with six millimeter bolts.

- To the upper parts of the resulting x-shaped structures bolted fasten the crossbar. The size of the side rails 40x25x350 mm.

- Each half of the chair is secured by the tip. There must be a spike on the arch, and a groove on the leg. Fastening is made with glue.

- Next, we fill the space between the backrest and seat bars with narrow bars in a staggered order so that they do not find each other when folded.

- Depending on the selected width of the beam for the seat and back, their number and the distance between them is calculated.

The work is completed by coating the product with stain, varnish or paint. Perfectly polished elements will allow to pay minimum attention to the decorative decoration of the chair and give the opportunity to leave it in pristine beauty.

For aesthetic completeness of the chair, its pleasant appearance, as well as for ease of use, it is recommended to round off all the bars. This will allow you to conveniently operate it even without decorative trim.

. This will allow you to conveniently operate it even without decorative trim.

We decorate the finished product

The best decor is an accentuated natural pattern of the wood from which the chair is made. But the seat of furniture can be decorated with soft materials that can be removable or attached directly to it.

A professional master does not wonder how to make a chair with his own hands.

For the decoration of the backs and seats usually take foam rubber and various fabrics or leatherette. You can also use eco-leather or even oilcloth.

In the arsenal of the pros, there must necessarily be both the simplest devices and professional tools.

It is recommended to provide home chairs with furniture sockets that protect the surface of the floor covering. The selection of the heels is determined by the design of the chair and its weight.

Wood should be treated with stain and varnish or covered with paint. Here's how to make a wood chair with your own hands for a beginner.

VIDEO:How to make a wooden chair. Do-it-yourself furniture # 2

50 photo ideas how to make a wooden chair with your own hands

Making a highchair with your own hands: drawings, sizes, diagrams

Making a highchair with your own hands: drawings, sizes, diagrams

How to make the restoration of a Viennese chair with your own hands. Tips and workshop

How to make the restoration of a Viennese chair with your own hands. Tips and workshop

How to make a stepladder chair with your own hands

How to make a stepladder chair with your own hands

Padding of chairs: from intention to result

Padding of chairs: from intention to result

What should be a chair for a first grader

What should be a chair for a first grader