Table with glass table top do it yourself

Table with glass table top do it yourself

Joiner's table do it yourself

When a serious repair is undertaken in a household, it is necessary that everything is at hand at any moment, which will allow you to use time with maximum benefit. For this, it is important to properly organize the workplace of the home master, if he is used to doing everything with his own hands. During repair or construction a significant place is occupied by woodwork. However, sawing timber on a stool or bench is inconvenient and long. Rational use of time and resources will help the desktop, also known as the workbench. Make it fit at home.

For most men, the garage is both a “home” for the car, a storage room and a workshop at the same time.

Content

The advantages of creating a workbench with your own hands

Not every owner believes that the workbench is constantly needed on the farm: it is needed only for the period of repair or reconstruction of the building, therefore, it prefers to rent it. But such an opinion is wrong, especially if he is the owner of a household standing on the ground. A joiner's workbench that appeared on the farm will be a real help for him. Making a design like this, the owner receives a number of advantages compared to using a workbench rented or bought in a building supermarket.

- It will save a significant amount of money that can be used for further home improvement.

- Acquire additional management experience and practical skills.

- It will have at its disposal a convenient desktop suitable for processing parts made of wood and metal.

- If the owner makes a workbench with his own hands, he can use it at any time.

Therefore, in the same room (well, if there is a basement) it is necessary to place the shelving and workplace.

Types of tables

There are various types of workbenches that have different uses.

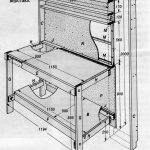

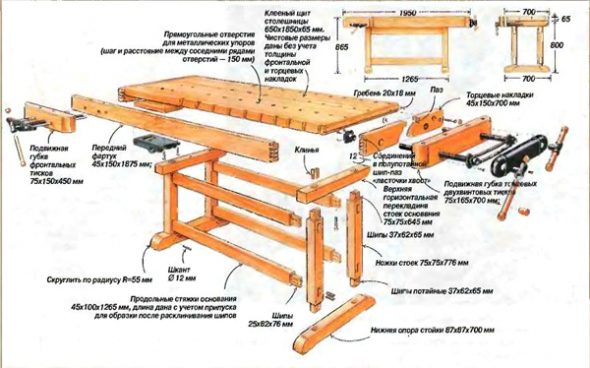

- Joiner's workbench for the manufacture of wooden parts. It is convenient to handle small wooden products, but it is not intended for the primary processing of wood. You will need a three-meter-long table-top, one meter wide. Details on it are fixed with wooden horizontal and vertical clips.

- Carpentry much more in all respects and heavier. Tree trunks are processed on it, boards, a bar and other preparations from a tree are cut.

- Universal table allows you to work with wood and metal; its table top is reinforced with metal tape and has wooden and metal clips.

Table for plumbing and car maintenance is in almost every garage.

There is another definition of the types of structures at the possible location.

- Mobile (portable). Used to perform small jobs with small parts. It is comfortable, quite light. It can be easily moved from one place to another. The joiner's table is completed with a vice of the small or average size that allows to use it for small metalwork works.

- Stationary desktop is massive and stable.It is possible to deal with the processing of lumber on it, but such a workbench is hardly useful to a home craftsman unless he constantly does woodworking.

- Assembled on connections using bolts. This is a kind of transformer: at any time it can be supplemented with special equipment and make the necessary changes, depending on the tasks to be solved.

And as a rule, it is self-made, that is, it is made taking into account the specific features of a particular room.

What type of design the home master chooses directly depends on what goals and objectives he sets:

- the desktop is needed to process small parts and manufacture small items only for the period of repair and construction work;

- the owner will use it constantly and work with small volumes of wooden parts;

- A workbench is needed to carry out the primary processing of wood, turning it into boards, cant on a permanent basis;

- It is supposed to use a table for periodic processing of small wooden and metal parts.

The shape and size are determined by the configuration of the room.

Experienced home craftsmen claim that it is possible to make a product even to a novice owner who does not have the skills to handle plumbing tools.

A workbench for a garage is often compared to a desk, because it provides the convenience of carrying out a variety of work and allows you to keep all the necessary tools at hand.

Material selection

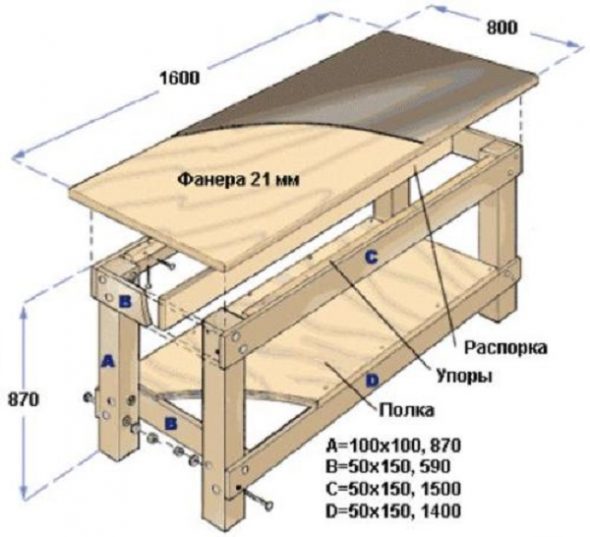

To make a workbench with your own hands, the master needs wood and metal. If it is intended to make a small table, then a wooden base will be suitable for it. Laminated chipboard, pressed plywood not less than 5 - 7 cm thick is suitable for the table top. For the stationary table, you can use well-planed boards that fit tightly to each other, and partially - metal.

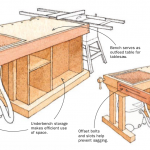

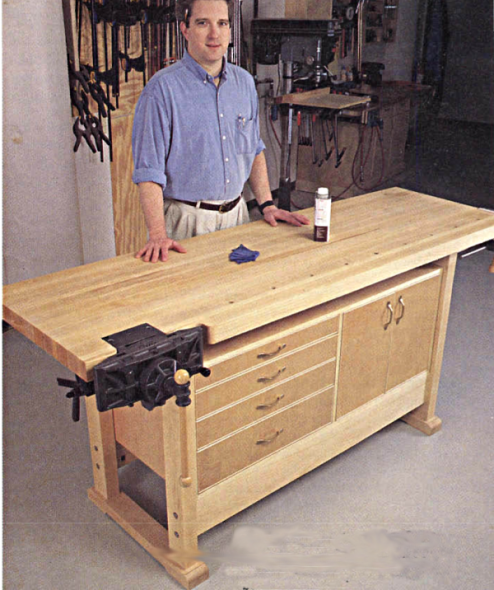

In addition to the tabletop, it has a large number of shelves and drawers.

And if at the disposal of the home master there is an unnecessary desk, then it will become a good basis. It is also convenient because it already has several drawers or compartments for storing tools.

The workplace of the motorist should be durable and stable.

Will find application in the design of the old door from a single blade. It will make a beautiful durable tabletop, which does not even require processing.

Under the table, tables with tools and consumables (drills, hacksaw blades, rags, etc.) must be placed.

The use of available materials at the farm for the manufacture of a carpentry table with their own hands will save time and money of the home craftsman.

It is irrational to make a monolithic cabinet from the table, you need to put your legs somewhere during sedentary work.

You can independently make a workbench of metal. It will turn out strong, reliable and heavy. But experience shows: the most acceptable is considered an intermediate option when the frame and the lid of the workbench are made of wood, and then sheathed with sheet metal.

However, both parties must be a set of shelves, if not sets of drawers.

A home craftsman who decides to make a workbench with his own hands will need a certain set of materials. What is needed for this is well known to him.

The workbench in the garage should not be part of the rack, therefore, the wall above it is a place for hanging tool storage.

And for those who still do not have enough experience, we have compiled a list of everything necessary for its manufacture:

- metal corner;

- steel strip and galvanized iron sheet;

- plywood;

- screws;

- anchor bolts;

- square tube;

- wooden boards;

- metal screws;

- paint.

Both metal and wooden workbenches have the right to life.

What tools are needed

A self-made small wooden joinery bench will occupy a worthy place in the home workshop.To make it, do not need a large number of tools.

On a steel sheet you can always put a piece of plywood or hardboard, and on a wooden surface - galvanized sheet.

You will need a standard set that can be found in every home:

- screwdriver;

- roulette;

- Bulgarian;

- jigsaw or handsaw;

- hammer.

First of all, we are determined with the ergonomics of the workplace.

Depending on what material will be used for the joinery workbench, the list of materials and tools may vary. For example, to make a metal desktop, do not do without a welding machine and electrodes.

The height of the workbench should be such that you do not have to bend your back, and at the same time, stand on tiptoes.

Where to put?

Before starting work, it is important to immediately determine why and how often the table will be used where it will be placed. Do not do without drawing. Answers to these questions will determine its size, material and order of manufacture.

We advise you to look at the tabletop at his wife in the kitchen.

The best place to accommodate the device can be considered that part of the room (garage or shed), where there is natural lighting. It is also important that there are electrical outlets near the workbench to connect power tools and a lamp. It is best if the light falls from the left or directly, then the working surface of the table will be lit during the day.

Design the dimensions of your work area.

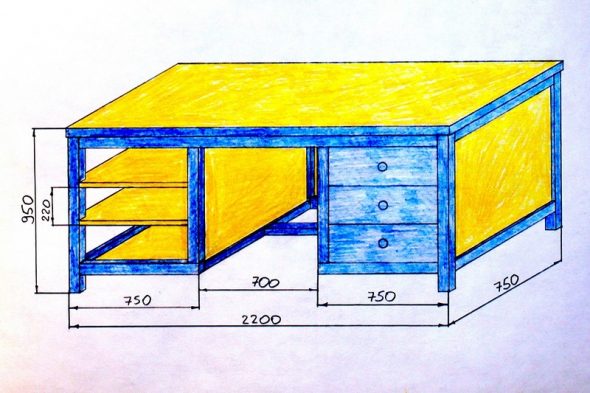

Then the parameters of the future construction are determined. Despite the existing rules on table size, if you make a carpentry workbench with your own hands, the home master will proceed from the expediency and the space actually available, so the table top will be such that tools and parts are freely accommodated without strict adherence to dimensions. The width is usually 50-60 cm; This size is considered optimal, as it allows you to freely reach the opposite edge of the tabletop.

A typical vertical table size is in the range of 850-950 mm.

Another important parameter is the height of the workbench. There are various ways to determine it, ranging from accurate mathematical calculations to popular experience, suggesting that the distance from the extreme point of a arm bent at the elbow to the floor be considered the best indicator. An experienced master can make it adjustable.

Perforated metal sheet is perfect as a wall for placing tools.

After determining the basic parameters of the product, you can proceed to assembly.

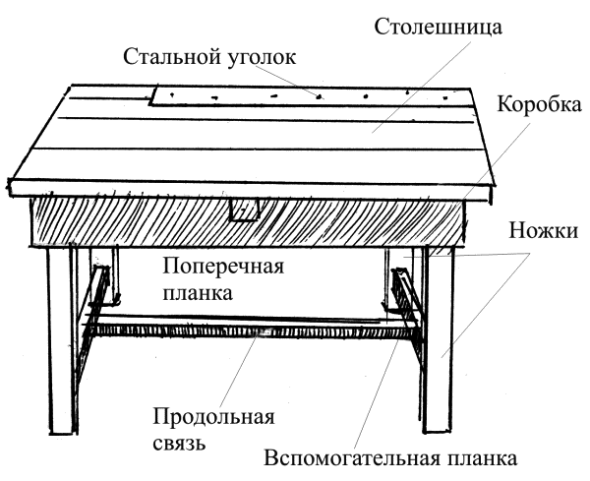

- At first, the legs are fixed (four supports from a steel angle, which are also joined by angles and fixed by welding from above and below.). The result is a rectangular welded structure.

- After making the frame start preparing the table top. Cut to size boards are laid out on the frame above and tightly fastened. With a frame countertop is connected with bolts. The working surface must be treated: oskrugana and smoked. The bottom must be fixed with crossbars or wooden bars. They are screwed to each of the elements of the resulting shield.

After its fastening, it is necessary to make the lining of the lid with metal (preferably, if it is galvanized). The metal sheet is fixed on the tabletop surface with self-tapping screws. If burrs form, they need to be stripped.

Cutting the workpiece should be prior to welding.

The main work on the manufacture of the workbench is completed on this, but in order to impart greater rigidity to the structure and attachment to the floor, metal corners can be welded from below. At will, it is possible to equip with boxes, regiments for the tool.

All welded joints are reinforced with a corner or steel strip.

From the necessary equipment on the workbench must necessarily find a place vise. They are hung on the front side of the table top and are used for fastening products.If there are often large parts in the work, there is a need to install several vices of different sizes.

The main thing - to strengthen all 90 ° connections.

Under the workbench, you can mount the shelves, where to place the various tools, the right tool or put the processed parts.

Be sure to impregnate the wood with antiseptic and fireproofing.

Carefully made with your own hands, carpentry workbench will be a convenient device for the work of a home wizard.

This design is close to the ideal of a self-made garage workbench.

VIDEO: do-it-yourself workbench.

Create your own workbench: 50 photo ideas

Table with glass table top do it yourself

Table with glass table top do it yourself

We make a comfortable party for the child with their own hands

We make a comfortable party for the child with their own hands

How to make a computer desk with your own hands

How to make a computer desk with your own hands

Attaching the table legs to the tabletop

Attaching the table legs to the tabletop

Unique dressing table do it yourself

Unique dressing table do it yourself

We make a table from solid wood with our own hands: from the choice of material to the final assembly

We make a table from solid wood with our own hands: from the choice of material to the final assembly