Making a folding table with your own hands

Making a folding table with your own hands

Round table do it yourself

Each owner wants to boast guests of their possessions. Especially nice to point out things done with their own hands. This adds special comfort to the site and special pride to the owner. Increasingly, in the garden plots there are flowerpots, flower beds, swings, ornaments, made independently. But the owners of this list are not limited to, and proceed to the creation of more complex products. So, today we offer to make a round table with your own hands, surprising family and friends.

The round shape is not the most ergonomic for a small space, but contributes to the confidential comfortable atmosphere of communication.

Content

The advantages of creating furniture with their own hands

Doubt whether to take up the job? Then let's talk about its benefits. I would like to note that this work is not difficult. We offer to make a simple model. Production does not take much time, effort, and does not require large joinery skills. Now about the benefits. Making a table with your own hands, you get the following advantages.

- Save a significant amount of money. Store products that are widely offered by distributors are quite expensive. Sometimes the proposed product is not worthy of the stated price. Selecting each particle with your own hands, you can make sure that it is worth the fixed price. And the whole product will cost much lower.

Massive wood table, made by hand

- You can choose any model. Shops will not always be able to offer a table that meets all your needs. Making furniture with your own hands, you can compile elements of different models, create your own innovation.

A simple model of a wooden table with a durable smooth tabletop and a solid base.

- You have the opportunity to choose a design. In this case, the story repeats. The store will not always find the desired product with the desired design. Sometimes the appearance of the table may not fit into the overall interior. So, you can pick up any design, doing all the work with their own hands.

Round table of cable reel with an unusual design

- Make a contribution to your own home. As a host, you will experience a bit of pride in upgrading your land or house without help.

Even a small round table can fill the atmosphere of any room with comfort.

We think now you have no doubts that the furniture you have created will benefit, and now you are already wondering how to make a round table with your own hands. Let's start looking for the answer!

Determine the appearance

Summer furniture option - a table and stools round shape

Round table in the interior of a small kitchen

Before proceeding to the detailed instructions decide what we want. The concept of "appearance" includes several items that have a number of options. Consider them, and we can determine the appearance of the future table. And together with this we will decide what is to be done and build an action plan.

| Criterion | Implementation options |

| Purpose | · Room;

· Street. |

| Type of construction | · Folding;

· usual; · With one leg; · With two or more legs. |

| Additional elements | · With or without drawers;

· With footboard; · Other optional items. |

| Material | · Natural wood;

· DSP; · Metal; · Plastic. |

Round folding transforming tables

Plastic folding table round shape

Now we will analyze in detail how the above described criteria influence our choice, determine the appearance of our offspring and get down to business.

Beautiful and roomy wooden table of a round shape in the interior of the living room

Purpose

This factor is important, it influences further actions. The table will be on the street - then it must be processed with special means that prevent its damage. He will stand in the house - the conditions are greatly simplified.

This factor affects others: the type of structure, the presence of additional elements and design. Depending on the location and its further functions, a model will be built. When this is a street version, additional boxes are needed. If the creation is intended for barbecue, it can be made without additions. In the case when the product is intended for the child, it must have the appropriate parameters and additions.

So, the other criteria depend on the functions assigned to the future creation. Therefore, determine in advance what is necessary to fully perform the intended functions.

Type of construction

We divide the types of tables in folding and normal. Depending on the choice, different tools will be needed and the assembly process varies. Define this criterion in advance.

White round table on one leg

Next, find out the number of legs. We can make a table with your own hands on one leg, two, three and four. All of these models are stable (in the case of proper design and assembly) and have a beautiful appearance. It all depends on your own preferences and product features.

Three-leg dining table

The type of design includes additional elements. Find out if you need a box inside or a footboard, it can be enough to make one shelf under the lid of the product. In this case, the determining factor is the destination.

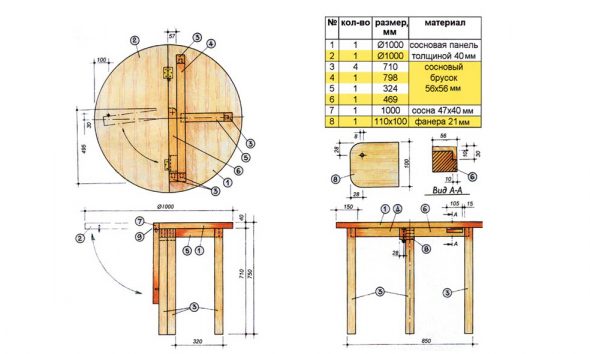

Scheme of a round wooden table for self-assembly

In general, think over everything in advance, and proceed to the creation of a drawing. It is at this stage that you can make corrections or allow errors to be inaccurate (then they must be corrected further on paper!).

Important!

To avoid mistakes in the design of the table, take seriously the creation of a drawing.

This stage is very important. If you can not go through it yourself, find a ready drawing on the Internet, adjust the dimensions, or entrust this business to the master.

Choosing a material

The most common material for creating a table with their own hands is a wooden array. That is natural wood. The basis can be pine, beech, oak, ash. The most commonly used pine. It responds well to processing and does not require special skills.

Dining table made of solid pine do it yourself

The next option is a chipboard (chipboard). They can be used, but not for the entire table, but only for certain parts, such as the lid, drawers or shelf. The legs should be made of solid wood for stability and durability of the product.

Large round table made of chipboard with metal legs

On the summer platforms you can see plastic tables and chairs. They can be made by hand, but for this you need to purchase items. Yes, and the creation of the table is reduced to the assembly of the parts received.

Plastic table and chairs for the street

Metal - a common material in the circle of people who have the skills of a welder and the appropriate tools. This foundation is strong, durable, and is well suited for outdoor products. But if you do not have the necessary skills, it is better to give preference to the tree. A round table with woodworking hands will fit any design and does not require special skills to create.

Round table with solid oak worktop and metal underframe

We select the decor

This is also an important part, and should be thought out in advance. Some types of décor, such as burning, must be included in the action plan in advance, as the product should be varnished only after the decor is displayed.

Select design depending on the purpose and location of the table. If this is a children's work area, make it bright, and white should be discarded. If it is intended for an outdoor gazebo, leave the color of natural wood, varnishing the product.

In general, the choice is yours. But do not forget that the decor should not interfere with the performance of the main function and be in harmony with the surroundings.

Getting Started

We decided on the main criteria and can proceed to the step-by-step analysis of the creation of the table. We will make a table of pine, as this is the most simple and common option. But before the assembly there are still a few preparatory steps to be done.

Prepare materials and tools

Assembling the table will not be difficult if all the preparatory work is done correctly. First you need to prepare the tools so as not to look for them in the process. In the arsenal should be:

- roulette;

- pencil;

- jigsaw;

- screwdriver or drill with a set of drills;

- building compass;

- clamps;

- Sander.

If any tool is missing, be sure to purchase it or borrow it from your neighbor, because without proper preparation a good product will not work.

You will also need the following materials:

- pine boards (for the cover);

- pine bars (for legs);

- self-tapping screws;

- wood glue;

- metal corners;

- varnish for wood;

- wood treatment agent;

- paint (if design implies).

Now that all preparations have been completed, we can proceed to the main stage of work.

Assembly process

For a simpler and quicker explanation, let's write out the work step by step.

Important!

Table elements are covered with water repellent before installation.

- Make a cover. To do this, fasten with the wood glue the required number of pine boards and secure them with clamps. After the glue dries, draw a circle on the resulting square. Cut a circle around the contour. That was the basis for our table.

We coat the sidewall of the boards with carpentry glue and apply them to each other, fasten the construction with clamps

Draw a circle tabletop using a construction compass

- Grind all the edges of the cover, and its surface. If necessary, begin edge processing with emery cloth.

Grinding machine handle all surfaces of the tabletop

- Take 3 bars of the same length and fix them with the help of corners and screws on the back side of the cover at the same distance from each other.

Cut the required length of the leg bar and round all the corners.

On three sides on each leg fasten on a metal corner, necessarily in the same plane

Self-fastening the legs to the tabletop

- Between the legs we attach jumpers for the strength of the product.

We make lintels of the same or smaller bars and fasten them to the legs with self-tapping screws.

- Cover the surface with 1-2 layers of varnish.

We treat the table surface with varnish

We hope that now you have no questions left how to make a round table. As you can see, it's pretty simple. It remains to apply the final touch, choosing any design. Leaving the product unpainted, you will emphasize its natural beauty. This option will be better than others, and recently it has become increasingly popular. Do not forget that the design must be registered in the preliminary work plan. This will help avoid surprises and make the process much easier.

Video: How to make a round table.

Ideas for the manufacture of round tables and their application in the interior of the house and on the street:

Making a folding table with your own hands

Making a folding table with your own hands

Making a glowing table with your own hands: the advantages of creating

Making a glowing table with your own hands: the advantages of creating

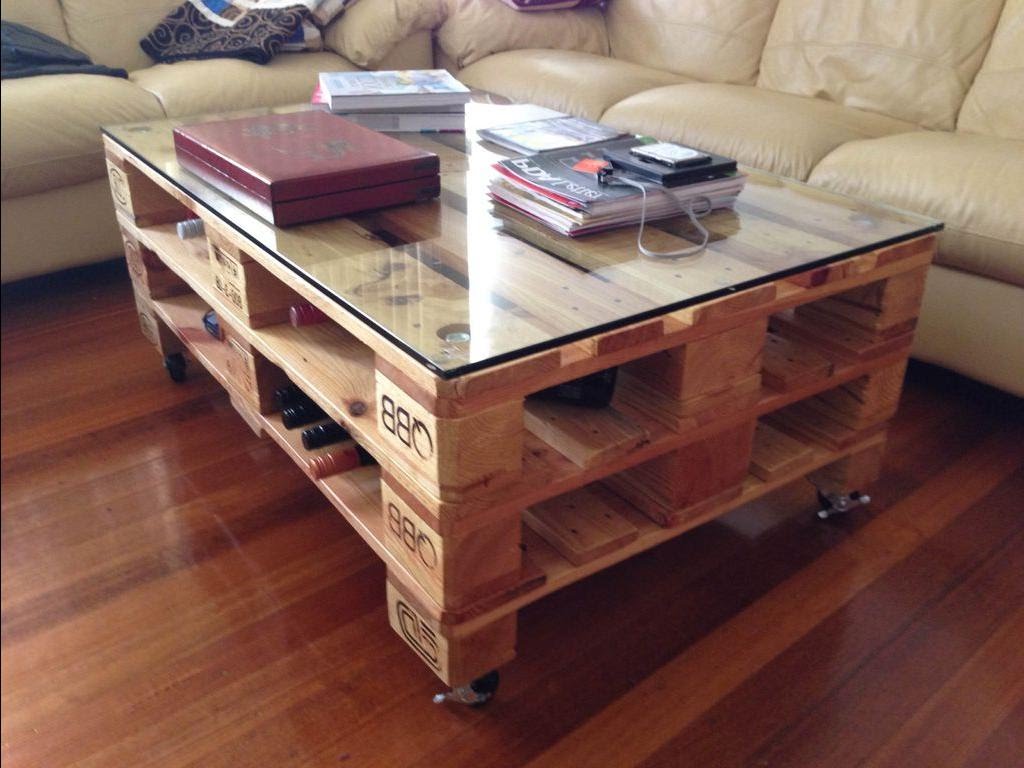

How to make a coffee table with your own hands?

How to make a coffee table with your own hands?

Table height does matter.

Table height does matter.

A table can be a console: do it yourself

A table can be a console: do it yourself

Unique dressing table do it yourself

Unique dressing table do it yourself