Corner wardrobe in the bedroom: good or bad?

Corner wardrobe in the bedroom: good or bad?

What you need to know before doing the closet in the hallway with your own hands

The hallway will be incomplete if it does not have a good spacious cabinet. It is not necessary to buy it, since the manufacturing process is quite simple.

Spacious wardrobe in the hallway niche

The advantages of this option:

- You can choose any project, the most suitable hallway in style, parameters;

- designers do not have to pay for the development of an individual project;

- material costs are minimal.

The main thing is that the furniture in the hallway should be spacious, compact, neat, not elaborate.

Details that need to be thought out when designing.

- must be exact dimensions;

- the presence of the crossbar to accommodate the hangers;

- hooks for clothes every day;

- one or more shelves for caps;

- cabinet for storing shoes.

- mirror;

- small drawers for small items (gloves, scarves, etc.).

Content

Necessary for work tools and materials

Furniture accessories for the wardrobe in the hall

To assemble the wardrobe in the hallway with your own hands, the following tools and accessories are prepared in advance:

- guides for the installation of boxes;

- tires, if conceived "coupe" with a sliding system;

- hinges and handles for doors;

- clothes hooks;

- calculated in accordance with the project, the number of nails screws, screws;

- wooden fasteners are also necessary: confermats, shkanty for furniture assembly;

- furniture corners (metal, plastic) and plugs;

- can not do without a standard set of tools (screwdriver, drill, electric jigsaw, wood saw, key for furniture confirmers, mallets, clamps, angle and construction level).

Tool for assembling the cabinet do it yourself

Materials better to take inexpensive, which is easy to process. For example, to make furniture from solid wood will not take even manufacturers with experience.

- Chipboard is the most acceptable option for a future product made by hand. This material is elementary to cut, process. The building material weighs a little, so it does not need reinforced fasteners or fittings. An important fact - low cost.

Wardrobe with chipboard with mirrored door

- Plywood is a lightweight, durable and more dense material, from which figured details can be obtained, as well as slit patterns.

Spacious eco-friendly plywood cabinet

- MDF can undergo various types of processing (painting, tinting, processing by stain, etc.). It is less durable than plywood.

Sliding wardrobe and bedside table from MDF in a hall

- Fiberboard must be purchased for the rear walls of the elements.

Fiberboard for the back wall of the cabinet in the hallway

- Wooden bar for frame construction.

Bar wooden for a framework of a self-made case

- Edged boards (usually made of pine).

Edged board (pine)

- Drywall for interior equipment built niches.

Homemade closet in the hallway

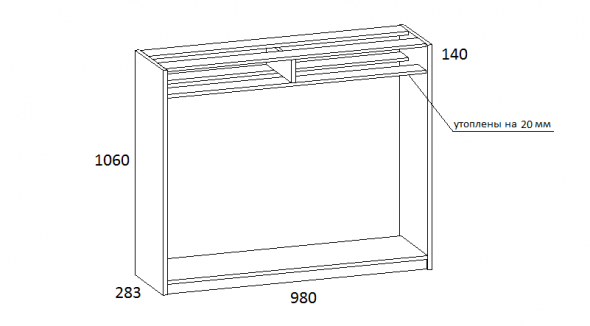

Most responsibly need to approach the removal of sizes. Assuming miscalculation, all subsequent work will be difficult or nothing at all. There are various ready-made options with suitable sizes.If the finished drawings are not suitable, and drawing skills are weak, you need to involve a specialist for this stage, who will design the project with the required dimensions. Cut the materials and make the edging of the end parts better in a store that sells construction material. The services of the store are inexpensive, but the time for this is significant.

Assembling the wardrobe

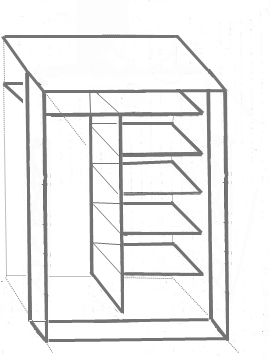

This model belongs to the built-in, it is easier to produce, since the parts do not need to be calculated and cut out. The complexity of this option is that it is necessary to take into account the peculiarities of the walls and floors.

An ideal solution for such furniture would be a niche with a sliding system, equipped with several shelves, a crossbar for hangers. The installation of the casements in this case is the same as that of interior doors (wall and floor are involved).

Very often, a wardrobe is made in the corner of the room. This model does not have one side and rear wall (and in some cases there is no floor and ceiling).

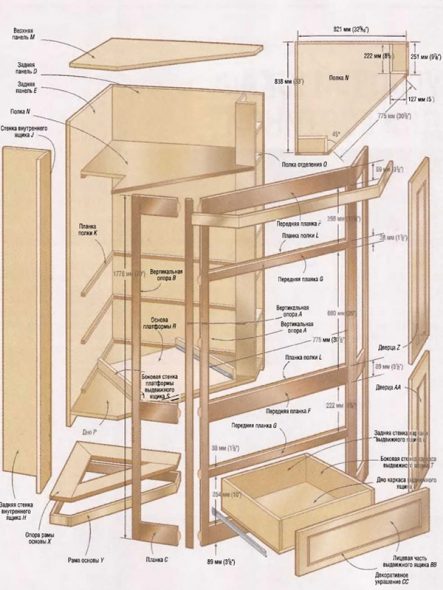

The base consists of a wooden frame, which consists of a pair of frames (front and side), assembled on screws or nails. If the project provides for the arrangement of shelves and partitions, in the designated places on the frame you need to fix the cross rails.

Instruction

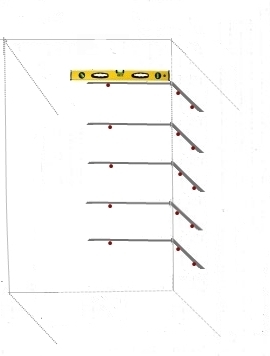

To mark the walls, floor, ceiling in places where the frame will be installed, drill out holes for fasteners. It is recommended to mark the place of the clip.

Making a layout under the shelves, set the corners

Fasten the front frame to the wall and ceiling with dowels. Check its verticality by applying a level.

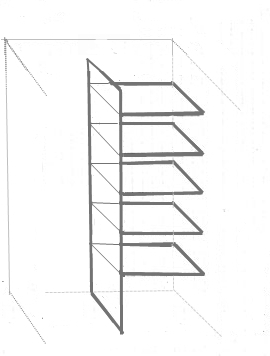

We put and fasten the shelves to the corners, install the vertical panel to the shelves inside the cabinet

Install side frame.

In the resulting niche on the walls fix the slats made of wood, intended for shelves (cut the shelves from plywood or chipboard). You can not fix the shelves, putting them on the slats or fix with nails.

On top of our design level horizontal shelf is laid

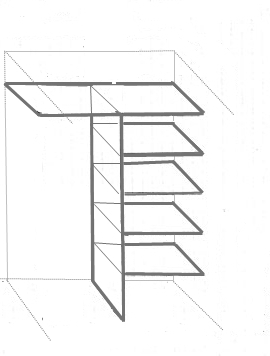

The side is sheathed with drywall or laminated chipboard. Drywall paste over or paint. The side part in which there will be a crossbeam with shoulders should be strong (chipboard, plywood, but not drywall).

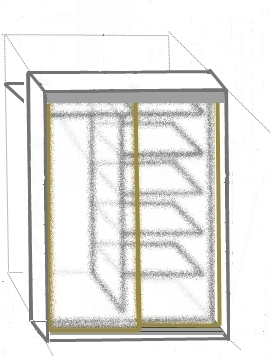

Preparing panels for the front of the cabinet

Fix the bottom and top panels

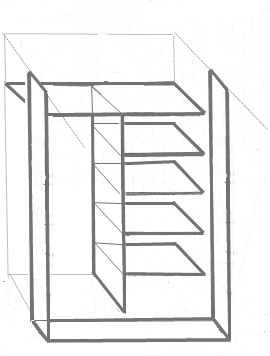

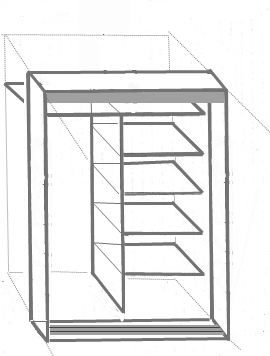

The final stage is the installation of sliding doors. The upper and lower guides are mounted respectively on the ceiling and on the floor.

Install guides for doors

It is very important to observe the exact dimensions. First try to install the layout of the future door. Take any part, the height of which is the same as that of the door, and set inside the upper tire. Check the value of verticality and mark the area where the lower guide will be mounted. The door must first be inserted, slightly pressing on the upper rollers, and then into the lower tire. To adjust the position of the door leaf adjusting screws are used. Properly installed door moves smoothly, unhindered.

We insert the doors into the guides, snap the latches and adjust the mechanisms in the roller systems

The above example is suitable for a simple construction of small dimensions, consisting of two halves. With a good hallway area, there is the possibility of making a more roomy model. Then the frame of the bars will not work. It is better to make the basis of chipboard, and its elements "fasten" with the help of a common floor and ceiling. This method will allow to place in a niche except shelves and a bar for hangers also drawers for small things and other details.

Such a product will be assembled as a designer on dowels and confirmatics. For this hardware, you must first drill holes. All this needs to be done especially carefully and patiently. All fixtures for the corners of the day are kept in the clamp.

Built-in two-door wardrobe in the hall

Corner Cabinet Assembly

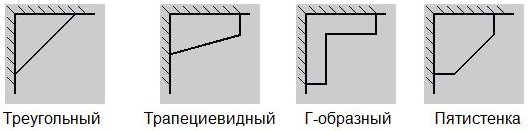

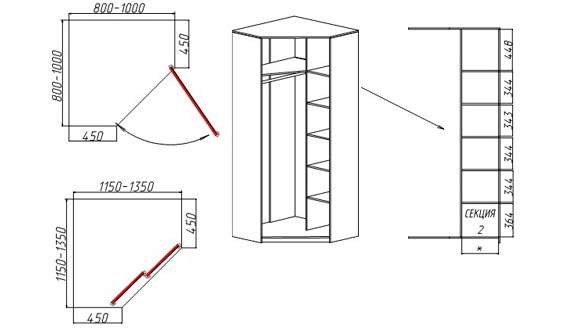

It will be easy to do with your own hands the corner module.For stability, modules are often made of durable solid materials (chipboard, plywood). Such products come in several forms:

- triangles;

- L-shaped;

- trapezium;

- five-wall

Basic configuration of corner cabinets

The most suitable for the hallway is a five-wall.

Built-in five-wall corner cabinet

Detailed layout of the corner cabinet

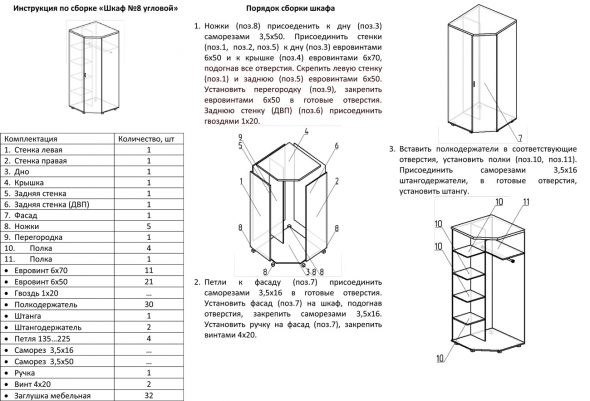

- In the drawing are marked sizes and areas of future fasteners. Shelves are installed on confirmatics.

Drawing of a corner cabinet with dimensions

- Jigsaw or hacksaw needed for cutting chipboard parts.

- Be sure to edge trim.

- Drill holes for installing dowels on one panel “from the face”, and on the other - from the end. Also need to drill places fasteners confirmats.

- Grease the dowels with glue and assemble the sides. As soon as the glue dries, fix the shelves on confirmatories.

- Install hooks.

- Glue on the side of the mirror.

Instructions for self-assembly corner cabinet

Shoe cabinet assembly

Comfortable do-it-yourself shoe rack

This is the simplest process, because everything that is needed in the work is sold to a building materials store.

- Order by the size of the framework of chipboard.

Detail cabinets for shoes do it yourself

- Buy "facade", accessories, basis from plastic for the leaning-back shelves.

Markup for holes

The design includes: outer frame, several shelves with partitions. The width of the structure depends on the maximum shoe size, and the height depends on the number of shelves.

Additive facades and pedestals for shoes

A good solution would be to combine a shoe cabinet with elements of a dresser. Or put it in a closet or corner closet, which have open facades.

On the Internet there is a lot of various information about how to make a wardrobe in the hallway with your own hands. Therefore, having studied all the available data, you can successfully construct the most suitable model.

Video: Wardrobe in the hallway, do it yourself

Photo ideas cabinets in the hallway for making their own hands:

Corner wardrobe in the bedroom: good or bad?

Corner wardrobe in the bedroom: good or bad?

Advantages and disadvantages of a corner cabinet in a small hallway

Advantages and disadvantages of a corner cabinet in a small hallway

How to make a wardrobe on the balcony do it yourself

How to make a wardrobe on the balcony do it yourself

Making a wardrobe made of wood with your own hands

Making a wardrobe made of wood with your own hands

Making a closet in the toilet with their own hands

Making a closet in the toilet with their own hands

Design features of the cabinet around the window

Design features of the cabinet around the window