We make furniture for a bath with your own hands. Recommendations, drawings and schemes of assembly

We make furniture for a bath with your own hands. Recommendations, drawings and schemes of assembly

Drawers for the home: step-by-step instructions for making

When arranging a home interior, the question of organizing a place to store household items, things, small accessories will certainly arise. For this purpose, various lockers, dressers, wardrobes, shelves. However, such furniture is more suitable for storage of large, medium items. Various small things are much easier to store in the drawers. This article describes their main advantages, presents detailed instructions for manufacturing.

Convenient storage of small parts in drawers

Content [Hide]

Drawer Benefits

The main task in the arrangement of home interior is to create a comfortable, functional, practical space. Ordinary cabinets can not always cope with this task. In standard furniture, a part of the space remains empty - you simply cannot reach there with your hand. Items in constant use should always be at hand. Store items available will help drawers.

Kitchen drawers allow you to place the necessary utensils as compact and functional as possible.

Such systems have become simply indispensable. They save space, have an attractive appearance, are easy to assemble yourself. They are very convenient to store underwear, cosmetics, kitchen utensils, towels, shoelaces, other trifles. Such furniture is needed in any room.

Very comfortable shoe drawers

Drawers for jewelry storage

Varieties

Drawer from chipboard

Chest of drawers of furniture board

Spacious drawers are made in different sizes, shapes, types. It is simply impossible to list the whole variety of types developed by furniture technologists. Consider the types of such furniture, depending on the two most common classifications in the table.

| Classification feature | Kinds |

| Case Material | DSP. Cheap material, easy to handle. Elements of chipboard can serve for a long time with proper fastening, handling. |

| Furniture shields. Sold in finished form. Differ in high durability, have sufficient density. Shields are more expensive chipboard, serve longer. | |

| Guides | Roller. The most sought after type. Roller guides are inexpensive, have a reliable mechanism, simple construction. |

| Telescopic. There are guides full vykata, incomplete. The first are more practical, allow full use of space. These guides are highly reliable. They are able to withstand a lot of weight - about forty kilograms, they are more expensive. | |

| Wooden planks. The most budget, simple option. Guides of this type can be made on their own from ordinary wood. They can be used to install small boxes. |

Roller guides for partial drawers

Full extension telescopic guides

Rail rails for pull-out drawers

Features of making their own hands

It is quite simple to make drawers with your own hands, adhering to the detailed instructions provided just below.Purchase finished products will seem much easier. However, the desired size is not always available.

Independent manufacture of furniture has its own characteristics. First you need to clearly define the materials. An excellent option would be to buy the following items: Particleboard for the sides, fiberboard - for the bottom, guides a full roll out. This is an excellent set of materials from which you can build a good box.

The next step is the creation of a graphical plan. On an ordinary piece of paper you need to draw the components of the future product, note their size, attachment points. Such a plan will help to complete the assembly as quickly as possible. The most difficult of all of the above is the calculation of dimensions. It is difficult to determine the size of the eye. Incorrectly chosen drawer sizes will significantly complicate the process of assembly and operation.

Calculation of parameters

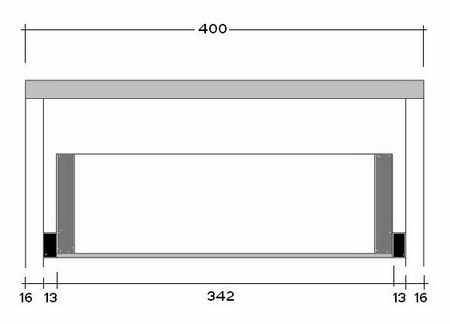

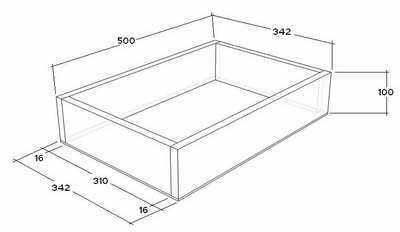

Drawing for the manufacture of sliding furniture drawer

Design drawers easy. First you need to calculate the required width. It should be 26 mm less than the width of the cabinet body - its internal opening. On each side for the installation of guides should remain about thirteen millimeters.

Next you need to know the length. It will depend on the depth of the cabinet. This parameter is required when selecting guides. They come in different lengths: from 250 to 800 mm. It is necessary to calculate the length of products in advance, only then buy guides for it. We measure the depth of the cabinet with an ordinary tape measure. Do not forget to leave in reserve a few tens of millimeters, depending on the design features of the furniture. Due to the standard dimensions of the guides, sometimes it is necessary to slightly reduce the length of the drawers.

Now is the time to decide on the height of the sides. The dimensions of the sides depend on the furniture design of the cabinet. In the manufacture of furniture products, the rule is used - the height of the drawer should be less than the height of the facade by 40-50 mm. There are no prerequisites for departing from this rule. The left space will provide an opportunity to correct mistakes, to properly adjust the work of the finished product.

Tools, materials

To assemble drawers, you need to prepare the following list of tools, materials:

- drill (sometimes you can replace it with a screwdriver, but you need a very powerful screwdriver);

- electric jigsaw (it will allow sawing chipboard as high as possible, eliminating damage, chips);

- ruler;

- building angle;

- rag;

- knife;

- pencil;

- roulette;

- studs, screws, fasteners;

- guides;

- the main material for the manufacture of construction.

When buying rails, design elements for future drawers, you need to consider several important criteria. The first is strength, high quality. Materials must withstand the load, do not lose their qualities after several years of operation. The second criterion is resistance to damage. A feature of these boxes is their frequent use. By extending the construction, slight damage can be easily inflicted. Durable material must withstand small shocks, collisions with the design of the cabinet.

Step-by-step instruction

Sketch and drawer sizes

So how do you make the drawer yourself? Consider step by step instructions.

- Collecting thumbs. First you need to fully assemble the frame of the box. You can mark the guides on the side of the cabinet.

Ready assembled bedside cabinet with drawers

Bedside frame with top panel

We apply markings on all sections and for all drawers for guides for sliding drawers.

- Fastening the side parts of the guides. For this you need 3x15 screws. They are usually sold together.

We fix the guides on the side panel with a screwdriver, constantly checking the markings.

Install the mating part of the guides on the side walls of the boxes

Drawer Side Panel

Correctly installed side panel

- Cut box items. For ease of operation, we use a previously prepared graphic plan, where all sizes are indicated. Chipboard mode jigsaw.

We connect fragments of boxes

Nightstand without front panels

- Bond prepared elements among themselves. We act according to the plan. For fastening use special furniture hardware. Fasteners must be durable, high quality;

Apply glue to the drawers and install the panel

Fix the panel with a corner

- Installation of the bottom. Attach the bottom to the frame can be small studs.

Fasten the bottom of the box

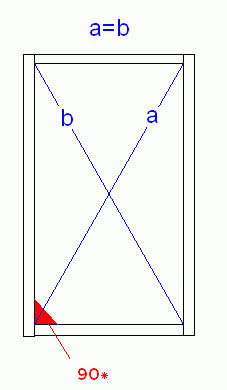

Checking the diagonals of the boxes for the presence of distortions

- Fastening the second part of the guides. We use screws. Their size will depend on the type of rails selected.

- Fastening facades. Facades it is important to properly set. The gap between the boxes should be the same. You can adjust the position of the facades with ordinary tape. We glue double-sided tape on the front walls, temporarily fasten the facades, adjust the gaps. Drill holes, remove the tape, finally fasten the facades. The box is ready!

Installed panels

Finished nightstand with drawers

Video: Drawer Assembly

We make furniture for a bath with your own hands. Recommendations, drawings and schemes of assembly

We make furniture for a bath with your own hands. Recommendations, drawings and schemes of assembly

Furniture for the hall. The subtleties of the right choice.

Furniture for the hall. The subtleties of the right choice.

Furniture arrangement according to the rules

Furniture arrangement according to the rules

How to make a bar stool with your own hands?

How to make a bar stool with your own hands?

How to glue the furniture with self-adhesive film.

How to glue the furniture with self-adhesive film.

Alteration of old furniture with their own hands: before and after

Alteration of old furniture with their own hands: before and after