Instructions for creating self plywood chairs

Instructions for creating self plywood chairs

We create sophisticated antique furniture with their own hands

Option of self-production of furniture for the room with antique styling

Antiques are always appreciated and appreciated by collectors and lovers of antiques. You can decorate the interior of the room, creating an extraordinary antique furniture with your own hands. The option of self-production of furniture products is economical and unique.

Content

- 1 The techniques of making aged furniture

- 2 Chemical processing

- 3 Heat treatment

- 4 Brushing

- 5 Coloring products "antique"

- 6 The advantages of personally created furniture products

- 7 Design and design of homemade antiques

- 8 How to age a table?

- 9 Making antique table

- 10 The final stage - decorating

- 11 Video: Wood aging. Master Class // FORUMHOUSE

- 12 50 interesting ideas for the use of antique furniture in the interior:

The techniques of making aged furniture

The effect of aged worn furniture

Making your own wood furniture, you should know the main ways of aging wood. Highly skilled craftsmen in the process of wood processing, use methods that age the surface of the furniture:

- chemical processing;

- finishing with fire;

- mechanical movements.

After studying the detailed information about each admission, even a beginning painter and carpenter will create an antique interior item.

Chemical processing

In chemical aging of wood, corrosive reagents are used.

Do-it-yourself furniture made of solid pine can be made using chemical finishing. This technique is characterized by treating the countertop with a chemical that forms an aging look.

Must be careful with chemical reagents.

When working with chemical elements, observe the following measures.

- Strictly adhere to the exact dosage of reagents.

- It is necessary to perform actions with chemicals in a respirator, and with caution - harmful substances affect human health.

- When working with chemicals, you need to use protective gloves.

Adhering to the rules described above, even a novice will create an antique wardrobe or chair with his own hands.

This is what chemical wood brushing looks like.

Heat treatment

Thermal aging of furniture takes place by burning

The option of heat treatment of the wood surface is characterized by performing actions with open fire. Joiners use a blowtorch, directing a stream of fire on the surface of the table. Under the influence of fire, the wood layer burns out intermittently, creating the desired effect.

Wood sample aged by firing

After finishing the fire manipulations, the master performs the following actions.

- Treats a wooden surface with sandpaper.

- Covers the prepared area with clear or matte varnish.

Combining chemical and heat treatment will add objects of uniqueness. Artificial aging of wood is achieved by mechanical finishing. The joiner processes the surface of a table or other product with a metal brush, making movements along the fibers. After finishing the machining, the specialist passes on the furniture with sandpaper, varnishes the finished area of the product.

Aged wood using chemical and thermal methods

Brushing

With the help of brushing you can decorate the interior in the country style, where the aged furniture is effectively complemented by wrought-iron elements.

You can make old furniture by brushing. Wizards create unique cabinets or tables with an antique look. Wood, processed by the brushing method, will ideally fit into the interior of the apartments in the style of "Provence" or "Country".

The described technique is suitable for processing floors, beams, panels and harmoniously looks with forging and large plants.

The technology of brushing implies aging of the furniture with the help of metal brushes, coarse skins, chisels and drills

Brushing is achieved:

- brushing the surface of the metal;

- cleaning from dust and wood residues;

- painting the finished area with a dark color;

- coated prepared countertop varnish.

This method can make products of various sizes.

Brush surface must be varnished

Brushing is suitable for objects made of wood, namely:

- pines;

- oak;

- larches;

- ash tree;

- walnut

Attention! Fruit trees can not be processed.

The sequence of brushing or texturing wood do it yourself

Coloring products "antique"

The aging effect manifests itself when dark areas look out through the light paint, and vice versa.

A popular method of aging wood is the coloring of furniture products. Usually painted shops, cabinets and tables. Original look all kinds of dressers and bookshelves. Preliminary preparation of the tree occurs, as in the previously described techniques. You can speed up the process with a drill and a grinding wheel. When choosing paint, select a blurred, fuzzy color. Professional joiners recommend using the paint used for interior painting of the wall and ceiling.

Paint aged wood in several layers

Before painting the product

- Remove accessories.

- Remove the emery paper top coat.

- The working area is cleaned with a soap solution from dirt and dust particles.

- The treated surface is dried.

- Carefully lower the roller into the paint and paint the product.

Surface coloring begins with difficult-to-work pieces of furniture.

It is recommended to start painting in an inconspicuous area in order to understand the whole process. It is necessary to paint, forming a broad and even strokes, warning of drips. Carefully paint the corners. The second layer of paintwork is applied only after the first layer is completely dry. Items begin to age after varnishing. Aging happens this way:

- fine-grained sandpaper is taken;

- sandpaper processed furniture parts, subject to abrasion (corners, protruding elements).

The erasing process is controlled by the master.

The advantages of personally created furniture products

Antique furniture, made by hand, has several advantages:

- Saving cash.

- Creating a unique vintage headset.

- The possibility of using different methods of work.

- Things keep a positive energy master.

- Self-created item that fits perfectly into the room.

Creating furniture with your own hands, it is worth considering its appearance to the smallest detail.

Design and design of homemade antiques

Before you make antique furniture with your own hands, you need to prepare drawings and diagrams of the desired products. It is worth considering that the product must understand, so the drawing must be carefully thought out and depicted on paper incremental assembly of parts. When creating a table, wardrobe or antique chairs with your own hands, consider a design that will fit into the interior of the apartment.

How to age a table?

To make an antique table with your own hands, you need to prepare the blueprints of the designed construction, the tool, the material and begin the creative process.

Required material

To create solid antique furniture is used:

- natural wood from which to create furniture;

- paints (stain, varnish);

- high-quality fittings (locks, mechanisms, handles), suitable in style to the intended product;

- decor items.

Having prepared the necessary material and drawings of the desired product, the processing of wood products begins.

Required Tools

Making a wooden antique table with your own hands, you will need:

- variegated sandpaper;

- brush on metal;

- hacksaw, saw;

- Grinding machine with different nozzles.

Tools for working with wood in the technique of artificial aging

Making antique table

Having thoroughly prepared, we consistently carry out the following steps.

- We disassemble the table into separate parts or make the parts of the product independently.

Remove the old countertop, gently prying evenly from all sides, so as not to damage the underframe

- We process with the help of files on wood or sandpaper surface elements of the product, removing the old paint and varnish.

We clean all surfaces and remove the old coating.

- We study the prepared sketch.

- We start brushing the metal along the fibers of the furniture.

We polish the coating so that the paint lies flat on the surface

- The depth of the grooves is adjustable by repeated actions.

On flat parts we use the grinding machine "Iron"

In thin profiles and threads, nothing is possible with a machine, you have to manually vyshkurivat every bend, every detail

- We clean the wood from dust particles.

Remove dirt and dust.

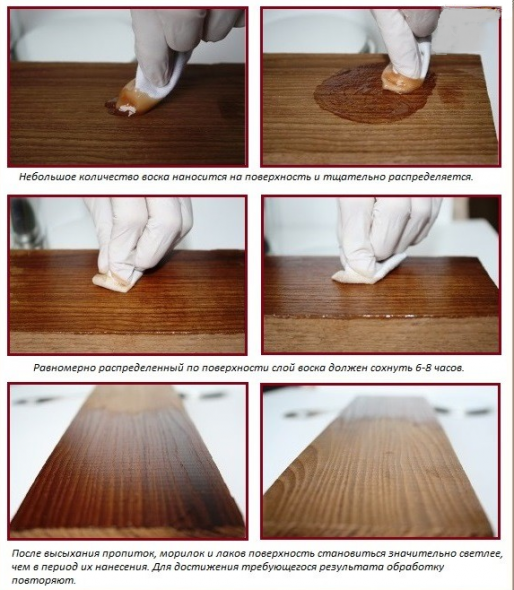

- Cover the surface with a dark stain (excess stain will be removed with a moistened sponge).

Morim water staining, because the walnut massif is very dense and requires deeper penetration

- We cover the product with prepared varnish.

We apply a finishing varnish on a carefully prepared surface.

- We leave the elements of the table to dry.

- After drying, the parts are assembled together according to the scheme (assembly takes place with the help of grooves, glue or furniture screws and hexagons).

Having finished to assemble a semi-antique table made with your own hands from high-quality wood, you will be satisfied with the result of the work. Such furniture will decorate the interior of the living room or kitchen.

Ready table after restoration do it yourself

The final stage - decorating

Wooden furniture, antique, made by hand, decorated with all sorts of decorative elements:

- acanthus;

- molding;

- overlaid elements;

- cartouche;

- applied pattern, etc.

Decorated with his own hands aged chairs, beds, cabinets, look original and fit into the home interior style "country" or "Provence." Self-made antique furniture demonstrates the good taste and sense of style of the owner.

Video: Wood aging. Master Class // FORUMHOUSE

50 interesting ideas for the use of antique furniture in the interior:

Instructions for creating self plywood chairs

Instructions for creating self plywood chairs

Making a wall for the house with your own hands

Making a wall for the house with your own hands

How to arrange the furniture in different rooms.

How to arrange the furniture in different rooms.

How to arrange furniture in a narrow room

How to arrange furniture in a narrow room

Kitchen set for a small kitchen

Kitchen set for a small kitchen

How to clean furniture from scotch with improvised means

How to clean furniture from scotch with improvised means