High-tech furniture - beauty in versatility

High-tech furniture - beauty in versatility

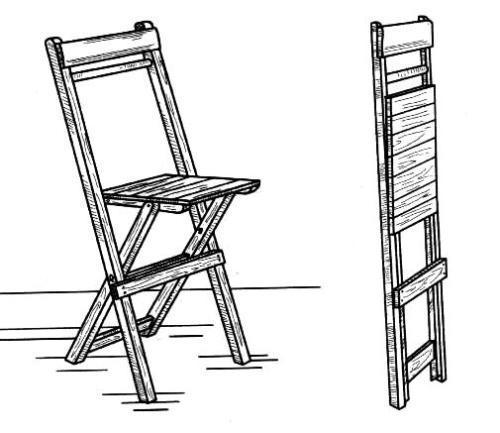

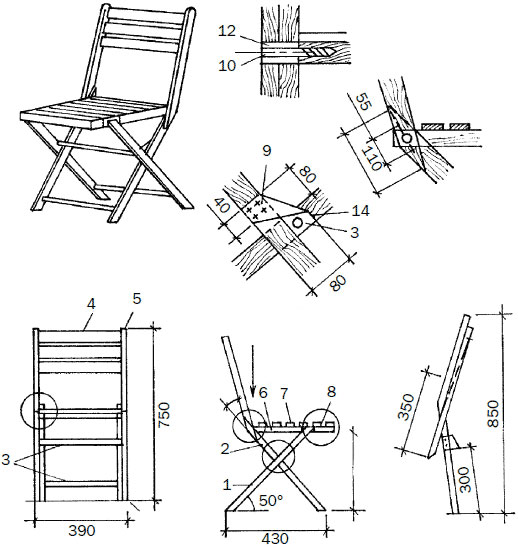

How to make a folding chair with your own hands?

Fishing is one of the popular men's entertainment. Have a good time on the shore of the reservoir. Experienced fishermen understand that comfortable fishing requires a comfortable seating position. Sitting on the logs is uncomfortable, dragging a bulky chair behind you is also not an option. The ideal solution to this issue would be a folding chair with a back, which when folded is compact and, when used, will help not to burden the back, which quickly gets tired of sitting for long.

Folding chair - ideal for lovers of fishing, outdoor recreation.

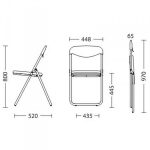

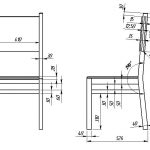

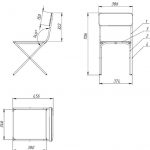

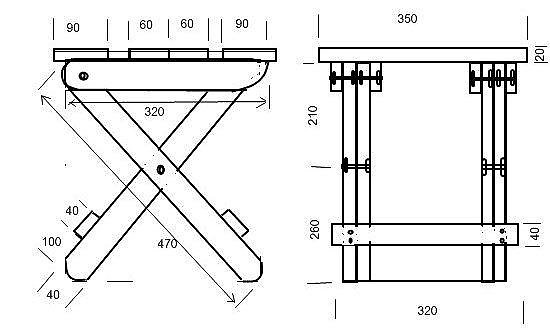

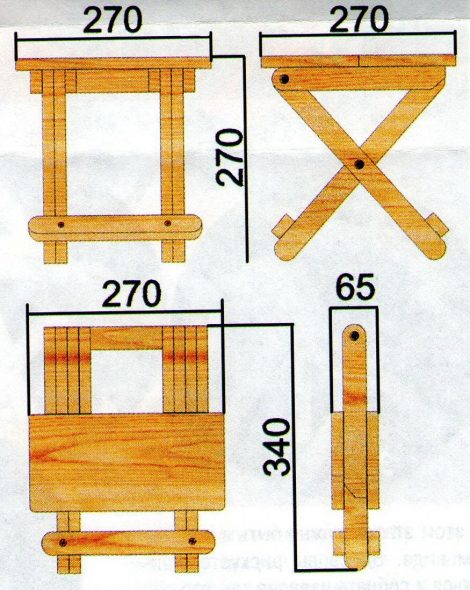

The height of the chair can be 350 mm - 450 mm.

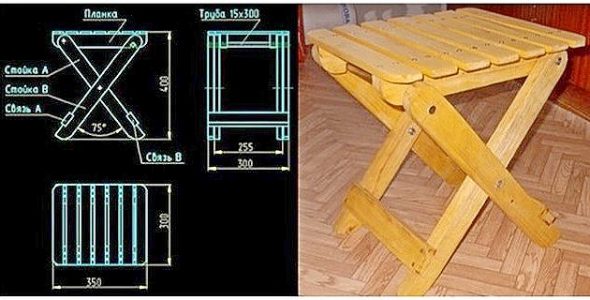

Shopping options are not always suitable, because often these products are either not very reliable, or are very expensive. Therefore, the most efficient way out is to make a folding chair for fishing with your own hands. The self-made stool not only helps to save money, but also allows you to roam the imagination and make a good product from quality material. The advantages of such a chair in its compactness, stability, ease of transportation and simple manufacture.

This piece of furniture is irreplaceable in the kitchen, in the country, because when folded it is compact enough and does not take up much space.

For the manufacture of a folding chair, you can use any wood species, birch will give it strength.

Content

Variety of folding chairs

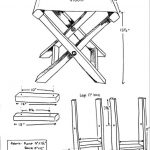

The most common versions of the chairs of such a plan - are options with back and without back.

- A stool without a back is easier to perform and less costly in terms of material, however, the first option is much more convenient to use. The back of a chair can be made of wood, that is, the product will be a solid construction, or the seat and back can be made of durable fabric that is stretched onto the base frame.

- You can also divide the chairs by type of legs - they can be straight, cross and solid. The material for the chair can be metal, plastic or wood. For the manufacture of metal or plastic chairs will require special tools and skills, so make them yourself will be quite difficult.

- The option with a wooden stool is the most simple, thanks to a wide range of materials, their affordable price and unpretentiousness of wood in work.

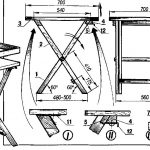

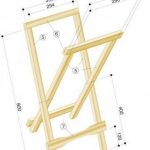

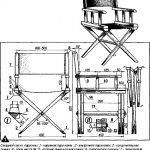

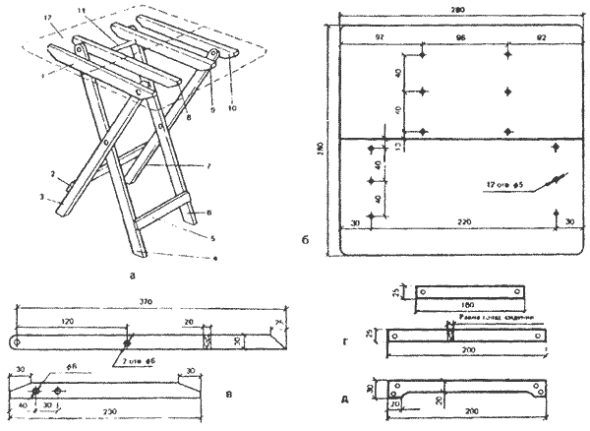

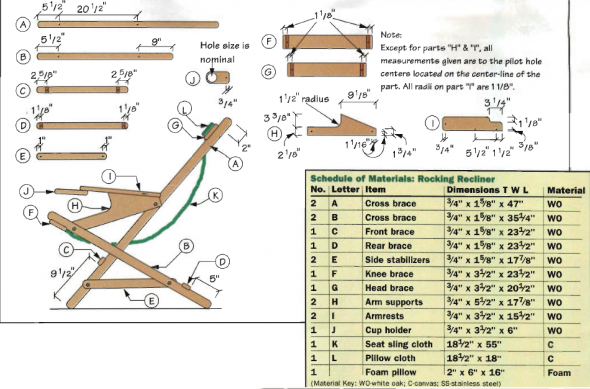

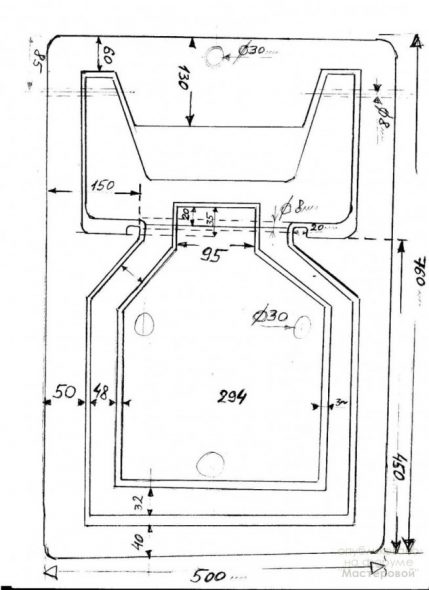

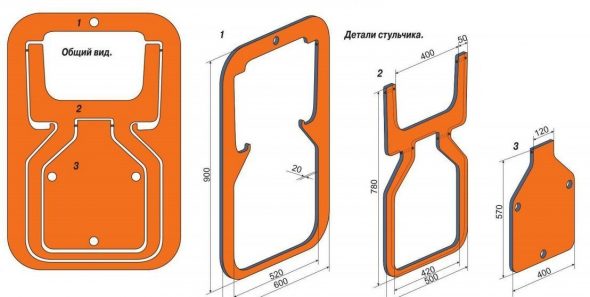

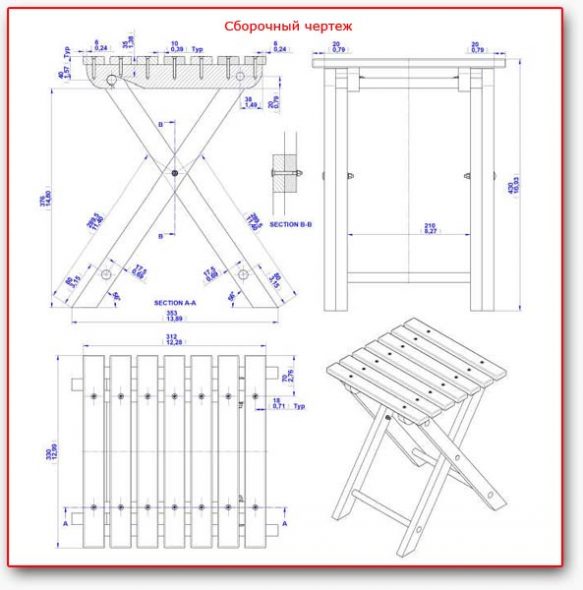

At first glance, the drawing of this object rather resembles a Rubik's cube, and it is completely unclear how you can build something by following it.

However, a ready-made chair suggests a slightly different idea - everything ingenious is simple.

Remember that the middle bars are placed in the same way as the outer, wide.

Materials and tools

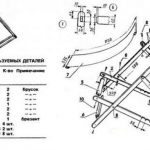

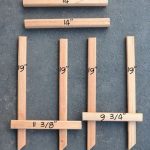

Based on the fact that the variant with materials from wood is the most simple and budgetary, we will choose it. The basis of the chair will be wooden bars, the size of which will depend on the size of a particular chair. They will serve as legs and carrier for the back.

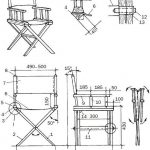

When starting the assembly, it is first necessary to place the axial bolts on the legs of the chair, the axis should not be located in the middle of the legs, but closer to their top, otherwise the chair will be high and will not become particularly resistant.

Folding chair is a very useful device in the household.

Without going into thoughts, let's move on to practical actions.

The materials for the seat and the very supporting part for the back of a person can be wooden slats or thick fabric, such as tarpaulin. The tree needs to be chosen qualitatively, it is desirable to stop the choice on firm grades of wood (a birch, an oak and others) as the service life of a product will depend on it. To connect the parts into a single design, you will need fasteners, in our case, these are bolts, nuts and washers for movable joints and screws on the tree for fixed joints.

When assembling, do not forget that the caps of the nuts and bolts need to be flush flush.

When assembling, do not forget that the caps of the nuts and bolts need to be flush flush.

Folding chair is a very useful device in the household.

From the tools to perform this work, a standard set of a carpenter, which is at home for almost every owner, is sufficient:

- drill;

- screwdriver or screwdriver set;

- hacksaw for wood and metal;

- wrenches, knife or scissors if you have to work with a cloth;

- file and sandpaper for subsequent removal of surface defects.

For the manufacture of a folding chair, you can use any wood species, birch will give it strength, but the pine will greatly facilitate the construction, only its compounds are not durable and can quickly loosen.

Folding chair - ideal for lovers of fishing, outdoor recreation.

Also for the final stage will require varnish or impregnation for wood, the use of which is necessary not only to give beauty to the appearance, but also to protect against parasites and moisture.

The described product is made without a handle, however, this gap is fairly easy to remove by placing portable handles between the inner legs.

Without much difficulty, you can make such a chair with your own hands, even without being a carpenter’s master.

Procedure

The process of making a chair is quite simple, and even a person without professional skills in this business can cope with it.

- It is necessary to assemble the seat by attaching the transverse rails to the base bars.

- This is followed by the assembly of the frame consisting of two bars, on top of which the backrest rails are mounted, in the middle - the crossbar for the seat (at the bottom of the frame will serve as the front legs of the product).

- The rear legs are equipped with two movable crossbars at the top and bottom.

- The upper crossbar is connected to the back, the lower - to the main frame by bolting.

- The seat is attached to the middle frame also with bolts. The result is a chair that, when raised, folds into a compact design that does not take up much space and has a small weight.

- In the case of working with fabrics or leather for a seat and back, a pre-measured and stitched case is put on the slats in the assembly process instead of wooden transverse parts.

Folding chair is a very useful device in the household.

It can be used in the garage, where there is always not enough space, to take on nature and simply, if necessary, use in the apartment.

This piece of furniture is irreplaceable in the kitchen, in the country, because when folded it is compact enough and does not take up much space.

Once the chair is ready, you need to make the final work. First, you should get rid of all the roughness and excess protrusions. The bolts are sunk into the base of the wood, the file and sandpaper eliminate defects, the varnish will add smoothness and emphasize the natural color of the wood, which in itself will already be beautiful. However, if fantasy requires more beauty, you can use the skills of burning and carving wood, or give the product a more interesting form at the design stage.

All that is needed is woodworking equipment, which is available in almost every garage or workshop of the joinery amateur, initial skill in working with wood and, most importantly, the desire to make.

It can be used in the garage, where there is always not enough space, to take on nature and simply, if necessary, use in the apartment.

Asking how to make a chair for fishing with your own hands, you can get a wonderful product that will faithfully serve for a long time. At the same time, you can save a lot of money and let your imagination fly by creating a truly unique work of authorship.

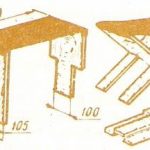

If necessary, it is possible to change the height of the assembled chair; to do this, it is enough to insert a different bar between the middle bars of the seat, with a section of approximately 20x20 mm.

For the manufacture of a folding chair, you can use any wood species, birch will give it strength, but the pine will greatly facilitate the construction, only its compounds are not durable and can quickly loosen.

However, a ready-made chair suggests a slightly different idea - everything ingenious is simple.

VIDEO: A folding chair with your own hands. Homemade folding chair

Foldable high chair do it yourself: 50 photo ideas

High-tech furniture - beauty in versatility

High-tech furniture - beauty in versatility

How to clean furniture from scotch with improvised means

How to clean furniture from scotch with improvised means

Furniture for the hall. The subtleties of the right choice.

Furniture for the hall. The subtleties of the right choice.

How to remove the old varnish from the furniture at home.

How to remove the old varnish from the furniture at home.

Kitchen set for a small kitchen

Kitchen set for a small kitchen

Design of children's furniture for a small room

Design of children's furniture for a small room