Furniture arrangement according to the rules

Furniture arrangement according to the rules

Assembling cabinet furniture with their own hands: the main stages

Collecting furniture on your own at home is a time-consuming exercise, however, it is an excellent tool for saving the family budget, as well as the opportunity to demonstrate the original design approach and aesthetic flair. Making furniture with their own hands is not too common, but it brings considerable benefits and moral satisfaction. The created product can be very stylish and beneficial to emphasize the overall interior design.

Fasteners pick up after you have decided on the basic material.

In order to cope with this not very simple but fascinating task, it is necessary to have at least the initial skills of working with the tool and to have care and accuracy. To create cabinet furniture, you can pick up cheap parts or use the materials available in the house.

The created product can be very stylish and beneficial to emphasize the overall interior design.

Content

- 1 General rules for the assembly of furniture

- 2 How to work with chipboard - the main material of cabinet furniture?

- 3 What tools are needed?

- 4 Preparation before assembly

- 5 The main stages of assembly

- 6 Furniture fittings

- 7 Furniture decoration

- 8 VIDEO: Production of cabinet furniture. A couple of tricks.

General rules for the assembly of furniture

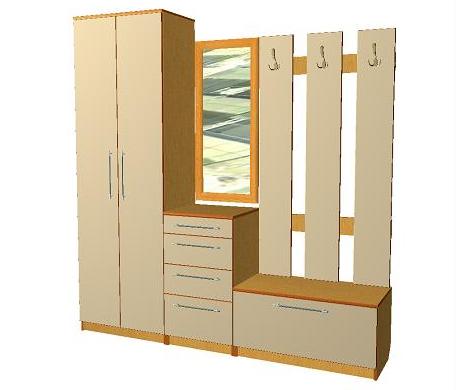

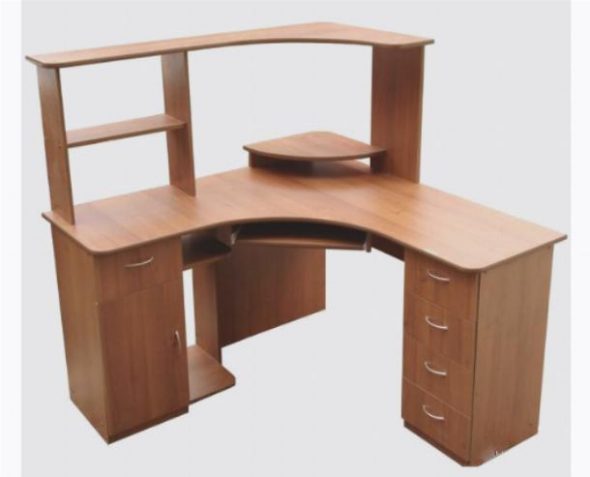

To assemble a cabinet or chest of drawers, you must first calculate the parameters of the future product. To make the cabinet furniture with their own hands, the first thing is to make a drawing with the dimensions of all the details.

Before making furniture prepare a drawing of the future product.

It is also necessary to determine what material you will use during assembly. Depending on this, fasteners, tools and auxiliary arsenal (sandpaper, etc.) are selected.

It is also necessary to determine what material you will use when assembling

Wood as a material can be “capricious”, it is important to choose high-quality boards with a good, even texture, dried and processed. Suitable birch, poplar, maple, aspen and other hardwood. Conifer need special conditions, so the pine or spruce should be chosen in combination with any other variety. Try not to pick up stratified rocks, so that when processing the base does not split.

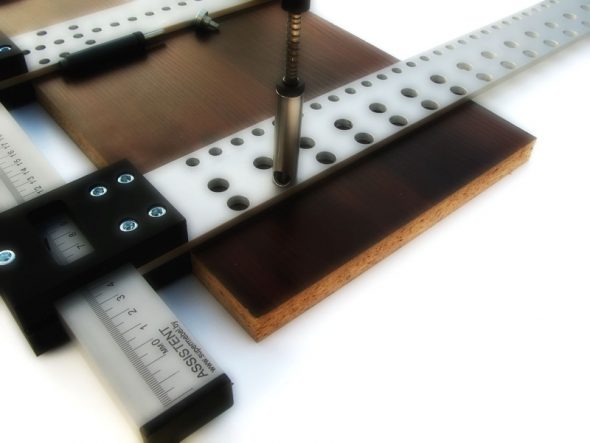

In the manufacture of cabinet furniture, pay attention to the fact that chipboard can crumble during tie-in mounts.

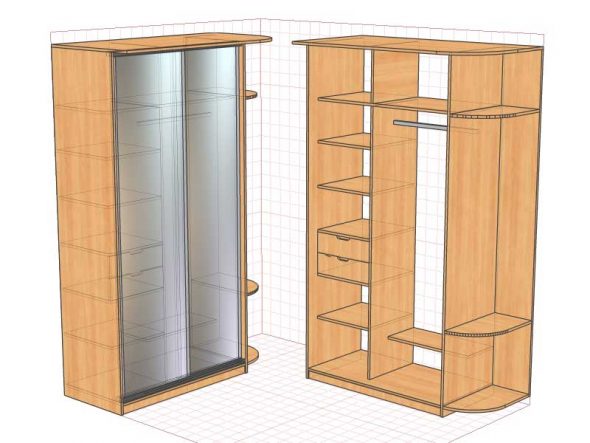

Cabinet furniture with their own hands can be made of chipboard, MDF or laminated chipboard (the last option is the most common). These materials are processed differently.

The material requires accuracy and accuracy in basting and actions.

All details of the future cabinet must be carefully checked with the drawings and neatly adjusted to the intended dimensions.

Wood as a material can be “capricious”, it is important to choose high-quality boards with a good, even texture, dried and processed.

Make a fit (trimming) will help you in a specialty store. This can also be done with a ruler, a pencil and a wood saw at home.

If desired, you can improve the appearance of the original inserts.

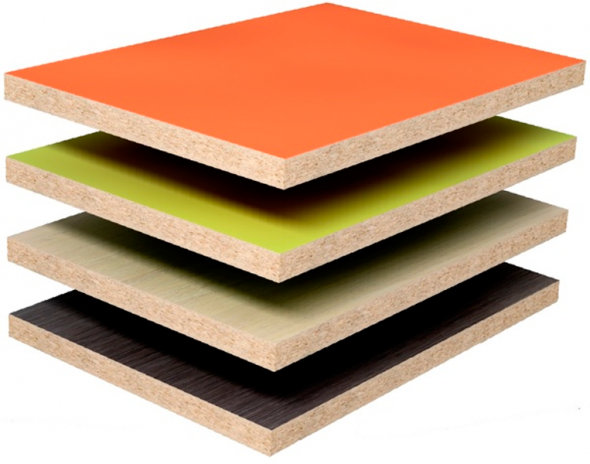

Chipboard panels must be covered with a protective compound - this will reduce the risk of evaporation of resinous substances. Other materials do not require such an approach.

Cabinet furniture with their own hands can be made of chipboard, MDF or laminated chipboard (the last option is the most common).

How to work with chipboard - the main material of cabinet furniture?

Such material as laminated chipboard is quite actively used in the manufacture of furniture. LDSP has a number of indisputable advantages over chipboard:

- holds fasteners better;

- inhibits the evaporation of formaldehydes;

- aesthetically pleasing;

- You can choose an interesting texture and color.

When using natural wood is recommended to cover it with varnish.

Do-it-yourself furniture includes the ability to handle the material, for example, trimming and closing the cuts with an edge to match the overall surface (this must be done to avoid evaporation of the chipboard adhesive composition. It must also be remembered that chipping and cracks in the laminated part are possible when cutting to size. For assembly cabinet furniture from laminated chipboard will require caution, care and accuracy.

Such material as laminated chipboard is quite actively used in the manufacture of furniture.

In the work, you can use power tools, which simplifies the attachment of a particular part to the body.

Cover panels need before assembly, and not after in order to avoid stains.

In the nursery, furniture from laminated chipboard is not always appropriate, especially if the room is small, poorly ventilated or located on the sunny side, and the base itself is not very high quality. Resins and chemical compounds can evaporate quickly and create an unfavorable atmosphere. This also applies to chipboard. It is better to prefer solid wood and plywood.

Cabinet furniture with their own hands implies the ability to process the material.

What tools are needed?

For the assembly of cabinet furniture are suitable tools that are in the house:

- screwdrivers;

- screwdrivers;

- Sander;

- jigsaw;

- hacksaw for wood;

- ruler;

- simple pencil.

The popular design with craquelure varnish makes the case of the cabinet look original and expensive.

Emery paper is suitable as a surface cleaning material. In order to measure the elements correctly, it is necessary to do this not on the floor, but on the table, preferably carpentry or something like it. Can be used as props when cutting off stools from the extra centimeters of stools.

To assemble a cabinet or chest of drawers, you must first calculate the parameters of the future product.

Preparation before assembly

The selected material - chipboard, laminated chipboard or solid wood panels - must be properly processed. Preparation of cabinet or chest parts consists in leveling the surfaces if it is not a laminated base, and also in their cleaning from roughness and burrs. The cut edges of chipboard can be simply sanded and closed with a laminated edge to match.

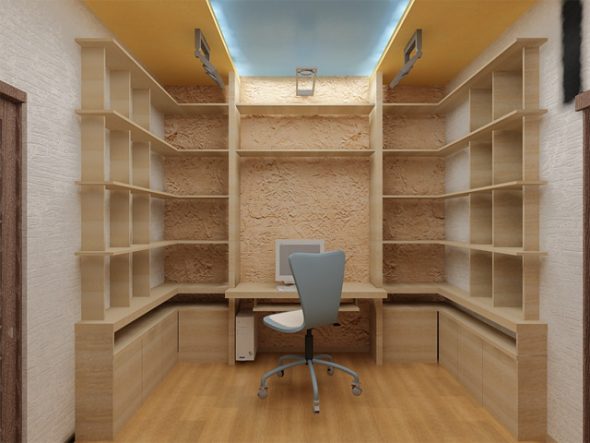

A practical addition serves as a spotlight.

Any material that you intend to use must be of high quality and well dried so that after production the product does not create hazardous chemical fumes in the room.

Before assembling furniture, you need to carefully measure the size of the area where the structure will be installed. For a cabinet with doors, it is required to leave some free space so that the doors can open without the possibility of friction against the walls.

In the work, you can use power tools, which simplifies the attachment of a particular part to the body.

Repeated details of the future product must be symmetrical to each other, otherwise misalignment is likely.

Fasteners pick up after you have decided on the basic material. Try to get reliable connecting details. They should be bought with a reserve so that they can be easily restored upon failure.

Emery paper is suitable as a surface cleaning material.

The main stages of assembly

Before making furniture prepare a drawing of the future product.It is necessary to once again verify the dimensions of the cabinet schematically indicated on the paper with the proportions of the prepared parts.

- Mark extra centimeters of laminated chipboard panels with a simple pencil, saw along the lines with a hacksaw, clean the edges and close them with the edge.

- Attach the side, bottom and top panels to the back panel using a screwdriver and self-tapping screws.

- Mark the space for hinges before hanging the doors. If the sash is heavy, increase the number of fasteners, otherwise the panels may twist under their own weight over time. The distance from the edge to the lower and upper loop should not be less than 12-13 cm.

- Secure the hinges and check the operation of the doors. They should fit snugly, without gaps and offsets. Do not forget to embed a mini-lock.

- For a cabinet with sliding doors, a roller mechanism should be selected, which will be located at the top and bottom of the panels. Most often used for this aluminum elements.

- If the legs are supposed to be, then they should be done before hanging the doors. After the assembly of cabinet furniture with your own hands is completed, check the stability of the structure, how smoothly the cabinet stands and whether it “sinks” in one direction or another.

- With the help of screws and slats make support for the shelves. The latter are adjusted to size after assembly of the cabinet body. For glass shelves sold special holders that do not damage the base.

- The drawers (if they are supposed to) are better equipped with guides, then they will be easily and freely extended without the possibility of twisting and sticking.

The selected material - chipboard, laminated chipboard or solid wood panels - must be properly processed

In the manufacture of cabinet furniture, pay attention to the fact that chipboard can crumble during tie-in mounts. The material requires accuracy and accuracy in basting and actions.

After applying each layer takes time to dry.

Furniture fittings

The choice of accessories for cabinet furniture is a moment no less responsible than the assembly itself.

| Cabinet hinges | Poorly selected loops are able to negate the results of your efforts.

|

| Four-hinge hinge mechanism | Today, this part is increasingly used. Adjustment is carried out both at the fastener stage and after completion of the installation work.

|

| Drawer guides | You can take a roller or ball. |

| Handles for sliding compartment covers and cabinet doors | They need to be matched to each other. They may differ in style - it is important to adhere to a single design for the facade or for internal filling. For children's cabinets or drawers, it is recommended to choose a streamlined shape so that the child does not hurt himself during movement or play.

|

Any material you intend to use should be of good quality and well dried.

Furniture decoration

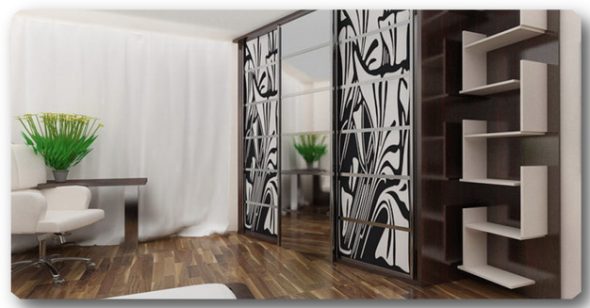

If desired, you can improve the appearance of the original inserts. It can be mirror panels, dividers, various patterns or stencils, ornament. A practical addition serves as a spotlight. In addition, it looks quite stylish, especially if there are glass or matte inserts.

When installing furniture, make sure that it does not fall in direct sunlight.

When using natural wood is recommended to cover it with varnish. Find the right shade is not difficult. To fix, you should apply the coating two or three times, then the surface will look smooth and even. After applying each layer takes time to dry. This will make the surface resistant to abrasion and fading. Cover panels need before assembly, and not after in order to avoid stains.

Repeated details of the future product must be symmetrical to each other, otherwise misalignment is likely

The popular design with craquelure varnish makes the case of the cabinet look original and expensive.

With the help of decoration, you can not only add style to a new piece of furniture, but also ennoble an old product.

With the help of decoration, you can not only add style to a new piece of furniture, but also ennoble an old product.

Tip: When installing furniture, make sure that it does not fall in direct sunlight. This will avoid fading of surfaces and cracking of the wooden base.

To create cabinet furniture, you can pick up cheap parts or use the materials available in the house.

VIDEO: Production of cabinet furniture. A couple of tricks.

Furniture arrangement according to the rules

Furniture arrangement according to the rules

Handmade furniture from improvised means

Handmade furniture from improvised means

We make furniture to give your own hands

We make furniture to give your own hands

We carry out aging of furniture in Provence style with your own hands

We carry out aging of furniture in Provence style with your own hands

Filling for frameless furniture

Filling for frameless furniture

We create furniture from plastic bottles with our own hands

We create furniture from plastic bottles with our own hands