Furniture arrangement according to the rules

Furniture arrangement according to the rules

Furniture-transformer do-it-yourself: tips, drawings and assembly schemes

Modern furniture market offers furniture of various styles for every taste and budget. In the exhibition halls you can find luxurious, similar to the royal beds, chairs, dressers, which can be placed in a huge room.

You can find more modest, but tastefully decorated elegant headsets. There is a very simple and cheap furniture.

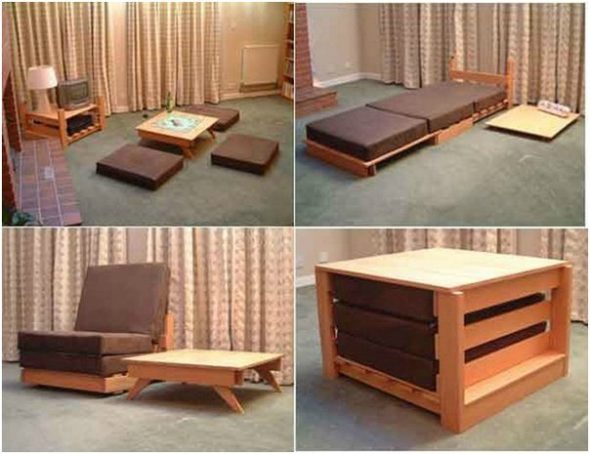

The transforming cube can serve as a bedside table, a table with poufs, an armchair and a full bed.

Alone is the transformer, which demonstrates the utmost compactness, versatility and utmost simplicity. It fits perfectly into the premises, decorated in a minimalist style, and allows you to increase the living space, fill it with air and light.

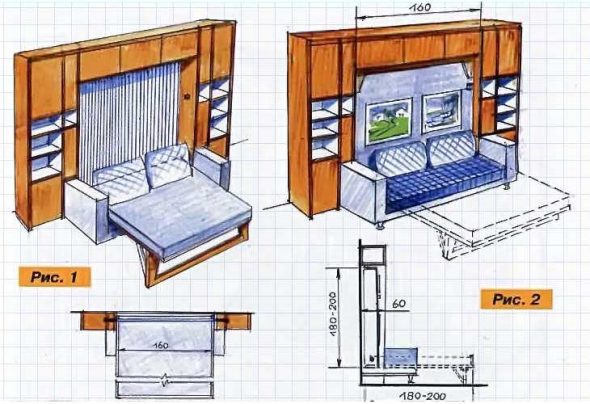

A double bed in the living room does not take up much space during the day and will become a comfortable sleeping place at night.

Content

We determine the design and construction

Functional transformer including a bed, sofa, table and ottomans for guests

Furniture-transformer is an invention that was widely used in small apartments, where it was impossible to install “full-fledged” sofas, beds, tables. There were a great number of such small-sized apartments.

The dresser easily turns into a computer desk and a shelf for the printer

However, over time, it was also noticed by those who have spacious enough rooms, but are used to minimalism or want to fill their dwelling with light and air as much as possible.

A simple and compact solution - a shelf under the window, and if necessary, this is a dining table with chairs.

Transformers not only allow to realize these tasks, but also solve another issue: the originality of the interior and the scope for design ideas. With the help of such furniture you can turn:

- bedroom - in the living room, and - vice versa;

- bed-wardrobe - in a cozy sofa;

- berth - in part of the wall space;

- a small chest, which takes up very little space - in a small table with ottoman.

The transforming bed is convenient in small and large rooms, as it can turn a room into a living room during the day and into a bedroom at night.

Space for various design solutions provides the use of modular furniture as an independent element, or together with other types of transformational:

- folding;

- retractable;

- rising (folding).

Transformer soft chair-bed folded and unfolded

With the help of various design solutions, including “endangered,” you can turn the living room into the nursery by evening, and in the small kitchen, “hide” the dining table after the meal.

Computer transforming table for sitting and standing

A nursery or an office can be equipped with a sofa or a full-sized berth, next to which there will appear cabinets and shelves assembled from various modules.

A transforming baby bed can serve as a playpen for a baby and a chest of drawers or a bed for a teenager, a cupboard and a shelf

They will decorate the room, perform functional tasks and give special originality to the room.

Sofa bed two-story - the strong and compact decision for a small nursery

Handmade transformer furniture drawings

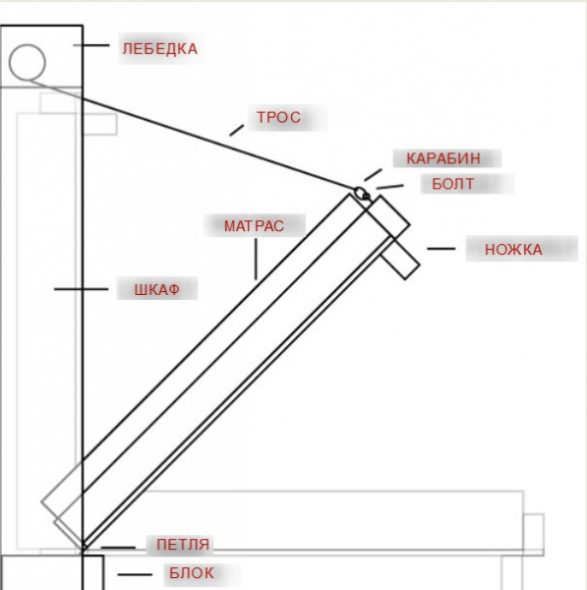

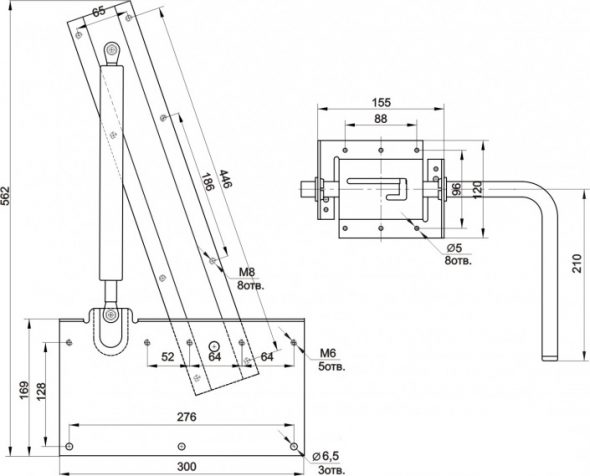

Scheme wardrobe beds transformer

Furniture-transformer can be ordered from the company that manufactures it, but if the house master has at least a little experience with carpentry tools with materials that are used to make it, he can do it himself.

The drawings can also be done independently or found on the Internet, where the workshops are also offered on drawing up sketches and drawings and making a transformer with your own hands.

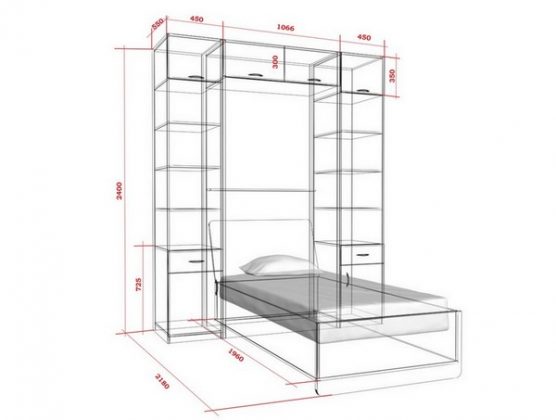

Drawing wardrobe with built-in bed

When making a drawing, it is necessary to consider:

- the dimensions of the room where the installation of the furniture transformer is expected;

- clear parameters of the new product;

- the materials to be used and their properties;

- the location of the product;

- type of transformer.

At drawing up of the drawing the limiting accuracy and adjustment of the sizes of a product is required.

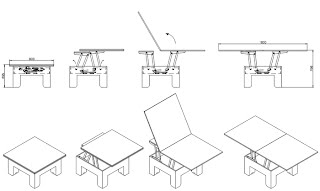

Transformer table layout with dimensions

Necessary materials

The set of necessary materials will directly depend on what type of furniture the home master will stop at. However, there is a list that is present with any choice.

| Material | Main settings | Where used |

| Chipboard | Plates from 10 to 22 mm thick | Manufacturing cabinets, shelves with high bending strength

Dressing |

| MDF | Durable sheets

Increased moisture resistance and density |

Countertops, Bench Seats, Kitchen Facades |

| Tree | Array, timber | Any products |

| Foam rubber | Soft, comfortable, inexpensive | For stuffing upholstered furniture |

| Glass | Thickness from | For the design of cabinets and shelves |

| Furniture fasteners | Different kinds | For all products |

| Furniture fittings | Different configuration and purpose | For decorating

At registration of doors of cases, boxes |

Required Tools

A set of necessary tools for making their own hands will also differ, depending on the type of furniture chosen. The general list will include:

- loops for facades;

- metal or plastic connecting squares;

- drawer guides;

- electric drill with a set of drills;

- clamps;

- cutter;

- hammer;

- iron;

- jigsaw or hacksaw;

- measuring instruments.

This list may vary, depending on the model chosen.

Manufacturing process: step by step instructions

Diagram of a simple homemade lifting bed

To make a transforming bed with your own hands, you need to move step by step, without missing any important points of preparation and execution of work.

You need to start with the choice of the location of the product, after which you can begin to make a sketch, and then - drawing.

Very compact transforming bed for interior solutions in the style of minimalism

After choosing the design of the product, clarifying its size and drawing up a drawing, you can proceed to manufacturing. Let's try to make a bed - a wardrobe. Despite the apparent complexity, it is not very difficult to make it. The main problem is the large size.

Instruction

- Material is selected and dimensions are made.

Details for the future bed

- A sketch is drawn up, a drawing is made.

- The frame can be used from an old bed or ordered in a furniture factory or in a workshop. The berth is defined in sizes 180x200.

The basis of the bed itself can be taken as an orthopedic base and mattress.

- In order to remain one base, the slats are removed from it.

- The frame is installed on the bars

The frame will be installed on the bars

- On the blanks of the cabinet is marking under the side.

Mark up the seats under the sides of the cabinet

- All parts of the structure are joined.

We join the base of the cabinet with its side panels

- Fixed top panel.

- Then the construction is fixed on the wall.

Fasten the top panel and fix the structure on the wall

- After mounted frame bed with a lifting mechanism and springs.

Diagram of the lifting mechanism and bed legs

- Now you can connect both parts of the transformer, returning the lamella to its original place.

We return the slats to the place for the foundation of the mattress

- The final stage - the fastening of the facade.

We install the facade in the form of improvised cabinet doors

Council Instead of a bar, you should not install the base on standard legs for furniture, because they can not withstand the weight of the structure.

Ready lifting mechanism will save your time and effort in the manufacture of transforming beds

To translate the bed in a horizontal position, you need to install the handles and use them.

Attention! The facade should be combined with the furniture in the room. As for the hardware, its location is not significant.

Video: Wardrobe bed DIY

Furniture arrangement according to the rules

Furniture arrangement according to the rules

The advantages of painting furniture do it yourself

The advantages of painting furniture do it yourself

Alteration of old furniture with their own hands: before and after

Alteration of old furniture with their own hands: before and after

We make upholstered furniture with their own hands

We make upholstered furniture with their own hands

Baroque furniture - an important detail of the project

Baroque furniture - an important detail of the project

Furniture Design Rules

Furniture Design Rules