Choosing furniture in the room for the boy

Choosing furniture in the room for the boy

Furniture from the profile pipe do it yourself

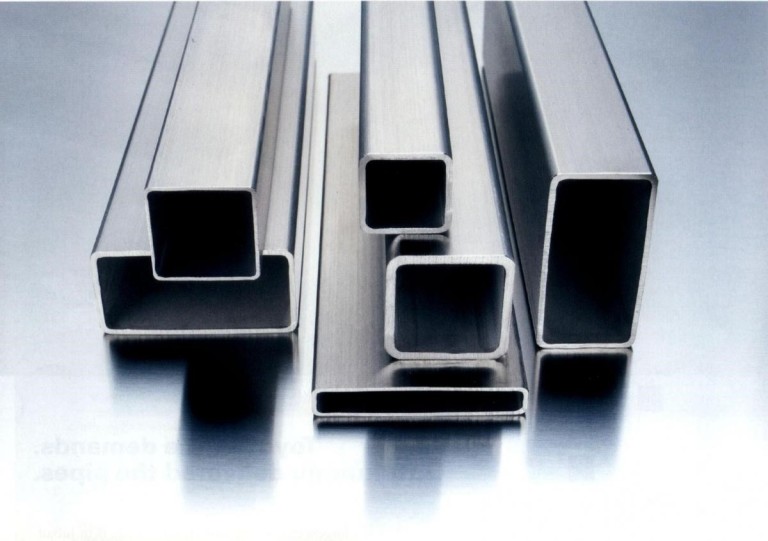

Profile pipes are a versatile material for their use in private households. The variety of products and the price in retail networks determine the popularity of a professional pipe among builders of summer houses and individual buildings.

The profile pipes have amazingly high strength properties.

The strength and quality of the materials used in the manufacture of pipes, the ability to use corrosion protection and other attractive factors determine the breadth of their use.

Finished structures will be able to withstand enormous loads, while avoiding even the slightest deformations.

Profile pipes are widely used in the manufacture of household items, the construction of small forms in areas adjacent to houses, the installation of the base of barriers, house frames, stair, balcony and window grilles, do-it-yourself metal furniture for the house and the street, tables, chairs, beds.

If corrosion does not hit steel, then it will serve you for tens or even hundreds of years.

Content

- 1 The benefits of creating products with their own hands

- 2 Design, construction and necessary materials

- 3 Required Tools

- 4 Recommendations for the manufacture of equipment for the production of bent-shaped pipes

- 5 Production of furniture from profile pipes

- 6 VIDEO: Loft-style table made of wood and shaped tubes.

- 7 50 photo ideas on creating furniture from shaped pipes:

The benefits of creating products with their own hands

In trading networks there are a lot of various products from shaped tube, but not all the desires of customers are taken into account by manufacturers of street and home furniture, stairs, flower bed fences and other things.

The created structure will not fall apart within even an impressive period.

Therefore, with the possibility of individual production of items from shaped tubes, they always prefer to create a product with their own hands, which in the following years will deliver not only joy in use, but also a sense of pride and self-satisfaction.

The manufacture of various products from shaped pipes with their own hands has recently become increasingly popular.

From the standpoint of practicality, the advantage of products created from pipe do it yourself, is the absolute understanding of all the advantages, disadvantages and maintainability of the product in contrast to the purchase of the store always mysterious parameters of the application.

Profile pipes are a versatile material from which you can create not only outdoor structures, but also stylish interior items.

A product created from pipe do it yourself, always meets the requirements of the manufacturer, who knows how to improve the product.

Design, construction and necessary materials

To create a product, you need imagination and knowledge of examples of such products, to have some skills as a locksmith and carpenter, a supply of necessary tools and a desire to achieve results.

Forged items are ubiquitous and individual. They can be used for benches, gates, shop windows, tables.

When building a frame house, it is necessary to pay special attention to the quality of the material, understanding that the supporting structure must be durable and reliable. Therefore, it is desirable to calculate the design or purchase of a finished project, in which the parameters of the profiles and pipes, the methods of their connection and processing, including anti-corrosion, are given.

From steel pipes of square or rectangular cross section, you can create a lot of useful things for the home.

If a fence is installed, it is convenient to use profiled pipes as posts, reinforced into the foundation of the fence or hammered into the ground.

Fastening the crossbars to the posts is possible, both by welding and bolts.

It is necessary to choose bolts in diameter for optimal fastening of the structure.

Gate hinges should preferably be bolted onto the poles, welding on pipes will be less reliable.

Frameworks of small structures playing the role of utility rooms on the estate, such as sheds, greenhouses, garage, poultry house and others, optimally made of shaped pipes.

At the same time, greenhouses can be made without foundation and portable from year to year from place to place.

Sports equipment such as racks for basketball hoops and badminton, playing tables and exercise benches are easily performed from shaped tube.

It is reliable, easy to install, affordable material.

The use of pipes for stairs, balcony railings, protective grills for windows requires the use of professional welding, but can be achieved with your own hands if you have skills.

Metal structures made of shaped pipes with their own hands, have a large number of advantages.

The greatest opportunities of use of profile pipes arise when it is necessary to make do-it-yourself metal furniture, while it does not matter garden or home furniture, shelves and shelves in basements, attics, garages, tables, chairs and benches in the gazebos near the barbecue and many others.

If you correctly carry out the calculation of the building, then it will be different durability and reliability.

Bent frames of chairs, sofas, tables, beds, cabinets and mezzanines, lamps and other items, what is enough imagination.

Profile pipe allows you to ensure the fulfillment of any fantasy in the house and on the estate.

The most interesting among the possible products is the furniture of the profile pipes because constantly at the cottage or the manor requires some kind of furniture, whether it be a bench or a shelf, a chair or a table, etc.

Therefore, we must always have in stock to have pipes and simple tools for creating furniture.

Required Tools

For the manufacture of various products requires special equipment and tools. To create a frame of the house or garage, and to make a chair at the same time it is necessary to have different accessories and tools.

If you wish, you can make the furniture aesthetic, by complicating the design of the frame and applying a decorative finish.

For the manufacture of furniture it is necessary to consider the basic operations that will have to perform in the process.

Pipes with a square cross section are easily assembled into the desired design.

Cutting blanks must be carried out with a circular saw called the “Bulgarian” or a manual hacksaw. When exact work is required, it is better to prefer a manual hacksaw or electric jigsaw.

To connect the parts you need a welding machine, but if there is no or no skills to use it, then you need an electric drill with a set of drills for metal and wood.

The main thing is to get a drawing, a “grinder” and a drill with bolts or a welding machine, and the rest, as they say, “a matter of technique”.

For stripping parts, a flat file is required, for large parts, a disc on metal for the "Bulgar" and an emery disc on the tree. Both discs are inexpensive and are always on sale in hardware stores. Emery cloth is needed for small works, mcage, tape measure, chisel, screwdriver, better electric screwdriver with a set of nozzles.

Tools for working with profile pipes.

For the manufacture of furniture from shaped tube accessories are required to bend the pipes. Making such a snap is easy, but requires time and careful execution.

The equipment is made for the production of the planned pipe bends.

The equipment in the course of works can change and be supplemented. Therefore, the basic requirements for tooling - it is simplicity, ease of manufacture, modification and addition.

Recommendations for the manufacture of equipment for the production of bent-shaped pipes

There are many ways to bend pipes. One of the simplest is the use of two pipes of a snap with a larger inner diameter and a larger length than a blank. The first tooling pipe is rigidly fixed on the workbench or on any plane; the variant is vertically packed into the ground. The workpiece bends by fixing with a wooden wedge a place of bending. shaped tube in the first pipe snap. The second pipe snap, worn on the rest of the profile, using as a shoulder, bend the profile to the desired degree. Such a bend occurs at one point.

Rocking chair with wrought iron elements looks quite aesthetic.

In the case when the bend has a complex configuration, the tooling becomes more complicated. The easiest option is to take a board 200x50 mm, the length will be determined by the workpiece, and on it to outline the reference points of the profile bend. Strengthen the board on a workbench, floor or other solid surface. Then, in the designated places, bolt the semicircular wooden stops around which the pipe is bent.

The shape of the stops determines the desired bend of the workpiece.

In three stops, the pipe is fixed, and then with a larger diameter pipe, we bend the workpiece in the stops, defining the bends.

In such a simple way, bend the details of the metal chair or the headboard of shaped tube.

Production of furniture from profile pipes

The furniture includes chairs, benches, tables, beds, shelves, wardrobes, beds.

All these items can be made with shaped tubes with ease.

Instructions for the manufacture of metal furniture is one and is determined by the sequence of execution of the following points.

- In accordance with the design drawing of the product, cut parts from the pipes.

- Strip the burrs of the cuts and drill the necessary holes.

- Using tooling to bend the details of the design of the product frame.

- Carry out the necessary welding of structural elements.

- Make a product design tie with bolts.

- Prepare and install fittings for furniture.

- Install wooden and plastic construction elements.

- Color the elements of all furniture products.

This creates furniture from the profile pipe for each specific product.

The presented instructions may be clarified in detail, some items may fall out. For the chair and for the hinged shelf, the instructions will be different, but it is advisable to create such an instruction before starting work.

All these structures will combine something in common, namely, incredibly high strength and resistance to any aggressive mechanical effects.

VIDEO: Loft-style table made of wood and shaped tubes.

50 photo ideas on creating furniture from shaped pipes:

Choosing furniture in the room for the boy

Choosing furniture in the room for the boy

We play on contrasts: the design of a light bedroom with dark furniture.

We play on contrasts: the design of a light bedroom with dark furniture.

How to glue the furniture with self-adhesive film.

How to glue the furniture with self-adhesive film.

Furniture made of cardboard. Everything's possible!

Furniture made of cardboard. Everything's possible!

Design of children's furniture for a small room

Design of children's furniture for a small room

We carry out aging of furniture in Provence style with your own hands

We carry out aging of furniture in Provence style with your own hands