Armchair with footrest - a convenient solution for home and office

Armchair with footrest - a convenient solution for home and office

How to make furniture from plywood

Handcrafted plywood furniture

If you have never created objects from plywood with your own hands, then you should think now. Buying finished products, there is an overpayment for the assembly. And often buying ready-made parts, we overpay for manual work on them. Creating hand-made materials such as plywood will be much cheaper.

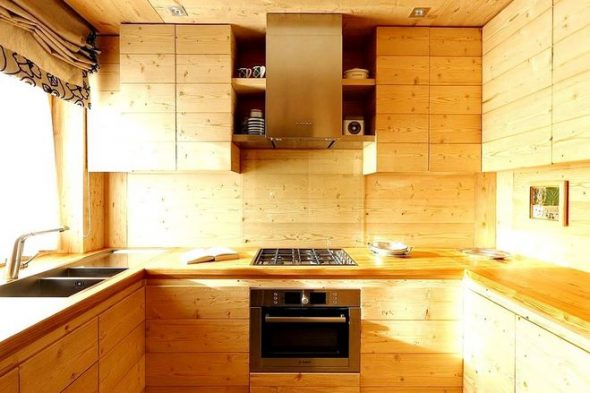

Kitchen set their plywood with built-in appliances

Before you start to create furniture from plywood with your own hands, you should decide on the design of the structure. You may find a suitable drawing on the Internet, or maybe you can draw it yourself. Familiarize yourself with the selection and processing of the material before starting work.

Independent cutting of the plywood chair according to the drawing

Content

- 1 Plywood selection

- 2 Raw material

- 3 Dimensions

- 4 Plywood processing

- 5 How to cut plywood with a jigsaw

- 6 How to cut plywood with a carpentry saw

- 7 How to cut plywood with a circular saw

- 8 Is it possible to cut plywood with a hand saw?

- 9 Features of material processing in the manufacture of furniture for the kitchen

- 10 Assembly

- 11 Dressing

- 12 Video: homemade plywood kitchen

Plywood selection

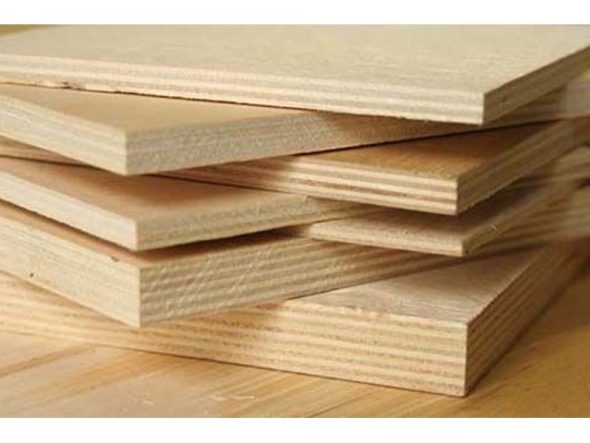

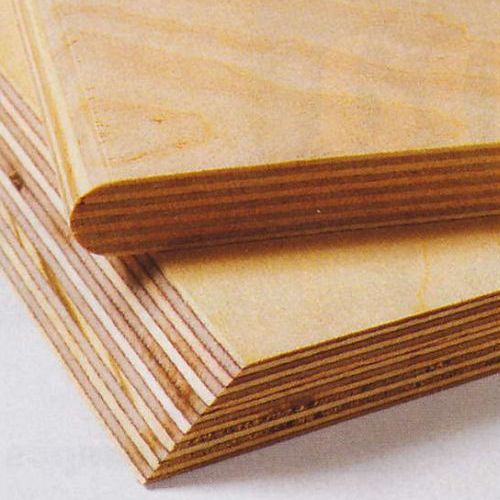

The texture of a new sheet of plywood

Plywood is made of thin layers of wood, called layers or veneer, glued together under the action of temperature and pressure, and the layers are laid perpendicular to the next. It consists of three thin layers of wood glued together with glue. Most manufacturers press raw materials into large flat sheets used in building construction. Other elements can be formed into simple or complex to use in the creation of furniture, boats and aircraft.

Plywood of different thickness in the construction industry

The use of thin layers of sawn timber as a method of construction has been known since 1500 BC. Then the best masters of Egypt tied up thin pieces of ebony with a piece of cedar coffin, which was used in the tomb of Tut-Ankh-Amon. This method was used by the Greeks and Romans to construct beautiful furniture and various things.

High-quality Finnish plywood for beautiful products.

Raw material

Plywood from different wood species with different structure and pattern

Plywood is made of hardwood and softwood, or their combinations. Typical hardwoods include ash, maple and oak. Composite plywood has the appearance of chipboard or solid pieces of lumber.

The type of glue used to join the wood layers depends on the specific application of the finished material. For softwood material, phenol-formaldehyde resin is usually used as an adhesive. For raw materials from hardwood used in construction, urea-formaldehyde resin is usually used as an adhesive.

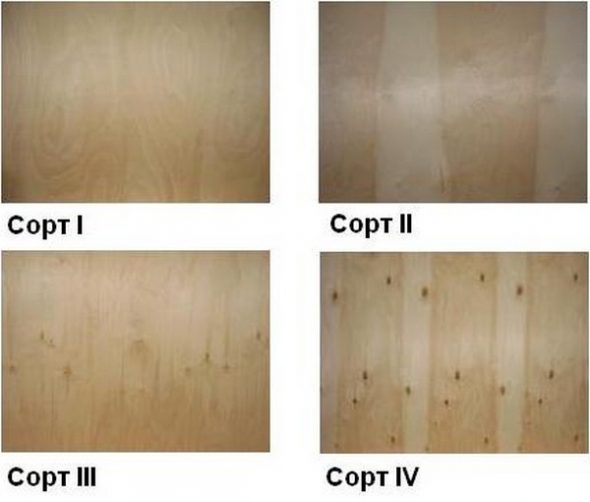

The use of plywood, depending on the grade according to GOST

There are two main classes of material, each has its own classification system. One class is known as building or industrial. This class is used primarily because of its durability and is assessed by its ability to act and the class of veneer. Another class is known as decorative. Plywood of this class is used mainly because of the appearance and sorted in descending order of resistance to moisture.

Beautiful decorative plywood for interior and furniture

Dimensions

Sheets usually have a thickness of 1.6 millimeters to 76 millimeters.The most common thicknesses are in the range of 6.4 millimeters to 19.0 millimeters.

Plywood processing

Contouring plywood to make future products

It doesn't matter if you are a skilled woodworker, carpenter or just an enthusiast who decided to create furniture with your own hands - you will need to cut plywood or veneered wood. Learning to cut without tears is not easy. It has a different structure. So some species are highly susceptible to splitting during processing. In fact, it does not matter which cutting tool to use, because it’s not a cutting tool. Each cutting tool must be used in a specific way to cut without gaps.

Ways of cutting plywood using discs on the table

How to cut plywood with a jigsaw

Cutting out small parts from plywood with an electric jigsaw

Most of those who craft plywood with their own hands, use a jigsaw because it is a cheap and affordable tool. The first thing you need to do is find a suitable blade for cutting plywood. Blades that you get in a jigsaw kit in most cases are not suitable for cutting plywood.

But even with the best available blade you can expect disappointment. There are several tricks to prevent some curiosities. You can mark the line for cutting with a pencil, and then, using a clerical knife and a ruler, cut the desired line, and then cut it with a jigsaw. Another trick is to stick tape on both sides of the cutting lines and then cut the tape with a jigsaw. From experience, I will say that using a proper blade with adhesive tape provides excellent results.

Electric jigsaw is an indispensable tool for making curved wood products

How to cut plywood with a carpentry saw

Makita table saw for cutting wood or plywood

If you are working on many woodworking projects, you probably have a table saw, and you use it for cutting plywood. The most important thing is to choose the right blade. Try a blade with 80 teeth and more to ensure minimal tearing.

If you do not have a suitable blade, I recommend that you use a saw blade to provide a clean cut. You must consider the sharpness of the cutter. No matter which blade you use, you will never reach a clean cut. Make sure that the blades are completely free of resin, as the resin greatly affects the performance, contributing to the breaking of the wood.

Your joiner's saw should be perfectly aligned when cutting. There is no trick to help keep your material if the blade is not aligned.

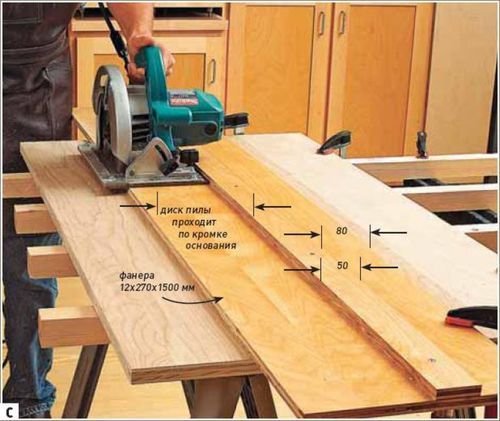

How to cut plywood with a circular saw

Sawing plywood with a circular saw

When cutting with a circular saw, the blade should be suitable for a plywood sheet. I recommend using a blade with 80 teeth and more. When you use a circular saw, you do not need to worry about the underside of a sheet of plywood, because the pull is only on the upper side. This is the easiest way to cut cleanly.

The duct tape trick also works on a circular saw, but it may be easier to make an easy cut along the cutting line, and then cut it off.

Compact and powerful hand-held circular saw for cutting plywood

Is it possible to cut plywood with a hand saw?

The right manual jigsaws for cutting on wood and plywood

The myth that you can not cut thin plywood or veneer hand saw - lies. The truth is, most of you didn't even try. But you can even cut into large sheets.

When you cut plywood with a hand saw - do not rush. Small and slow cuts are the best way to cut plywood without breaking.

Cut a circle from thin plywood by hand.

Features of material processing in the manufacture of furniture for the kitchen

Large, hand-made plywood kitchen

The strength and durability of plywood - the reasons why many high-quality kitchen cabinets have a plywood structure. Kitchen cabinets are subject to rapid wear. They open and close all day long. They are exposed to moisture, grease, heat, etc. Plywood withstands it all, so it is good as material for creating things throughout the house.

If you decide to start making furniture for the kitchen - Consider such factors as the overall layout of the kitchen and the dampness of the room, which will spoil your design; correctly calculate the thickness of the doors used during construction.

Interesting plywood kitchen with worktop and bar counter

Assembly

Prepared parts for assembling a small plywood cabinet

Prepare the space, preferably in the room where the furniture will be located. And remember that you will need to move freely around the structure during construction. Choose a well-ventilated or open work area and lay a tarp under the furniture.

Inventory tools and materials that are required. Let them be always at hand.

Decide how the build process will take place. Draw a rough plan for the connection of all parts, usually it does not take much time. It also helps to better present the final design and improve the design, if necessary.

If you need a hammer to hold 2 parts together, give preference to a rubber hammer (mallet).

Measure everything thoroughly. One mistake can lead to unnecessary costs.

Simple children's furniture made of plywood do it yourself

Dressing

A small chest of plywood with decor

Upon completion of the work you need to think about decorating furniture. Here are the most simple tips.

- Prepare the surface. Grind and lightly sand the entire part. Since the upper veneer is usually smooth, you just need to lightly wipe a piece of emery paper, remove dust with a brush and wipe with a damp cloth. This will remove all sticking wood fibers, improve surface absorption and remove excess lacquer or paint, if any. Then cover with a primer, and wait until it dries, if not yet varnished or painted.

- Add wheels. Rollers add height and make it easy to move furniture. All you have to do is roll the rollers.

- Remove the legs. Get rid of them for a more modern look.

- Change the door handles for more beautiful. (Before buying, make sure that the new equipment is suitable for the holes.)

- If you have created a bed - think about the beautiful headboard.

Painted plywood design furniture

Change the color scheme, or adjust the design of the room. Hardwood plywood often has a smooth upper veneer, making it easy to paint. You can even paint the laminated furniture, so if you do not like the color, you can always change it. Paint from top to bottom. For a small piece of furniture, you can use a wide brush with a flat bristle, smearing from top to bottom. For a large, flat surface, such as a tabletop, the coloring roller provides a smoother finish than a brush and is easier to process. Apply two coats of paint, allowing everyone to dry completely.

Regardless of your decor scheme, you may want to paint wood to highlight its natural features. If the furniture has a nice grain, use these stains and paint them with polyacrylic paint to highlight the beauty of the wood. This method works well with rustic or natural design themes.

Children's play house of plywood and wood for the children's room

Video: homemade plywood kitchen

Armchair with footrest - a convenient solution for home and office

Armchair with footrest - a convenient solution for home and office

Decoupage furniture wallpaper is cheap and beautiful

Decoupage furniture wallpaper is cheap and beautiful

DIY furniture making ideas

DIY furniture making ideas

Loft-style furniture - cozy and modern do-it-yourself

Loft-style furniture - cozy and modern do-it-yourself

How to make a folding chair with your own hands?

How to make a folding chair with your own hands?

What kind of interior fit furniture in the style of minimalism

What kind of interior fit furniture in the style of minimalism