All about the mechanisms of office rocking chairs.

All about the mechanisms of office rocking chairs.

How and why to make furniture from solid wood with their own hands

The furniture from the massif of a tree does not lose popularity, despite an abundance in the market of various by the form, and also more available materials. The fact is that natural wood not only has a pleasant appearance and creates a cozy atmosphere in an apartment or private house.

Wardrobe solid wood looks very strong and sturdy

Its performance is also unparalleled - products from solid wood will last more than a dozen years, while the safety and environmental friendliness of the material makes it suitable even for people with a tendency to allergies.

Some wood species even have medicinal properties, disinfecting the air in the room with the help of phytoncids contained in wood resin. Aesthetic appeal, durability, useful properties of wood have long made this material traditional for home furnishings. The only disadvantage of such furniture is its high cost in the market - but when deciding to create furniture from solid wood with your own hands, you will significantly save on the services of a master.

Content

Design

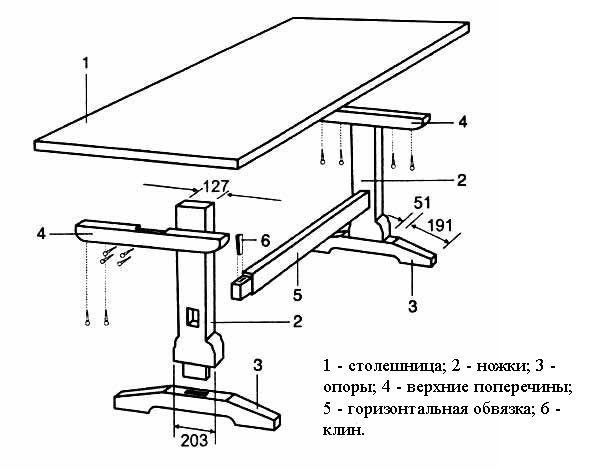

DIY wood dining table assembly scheme

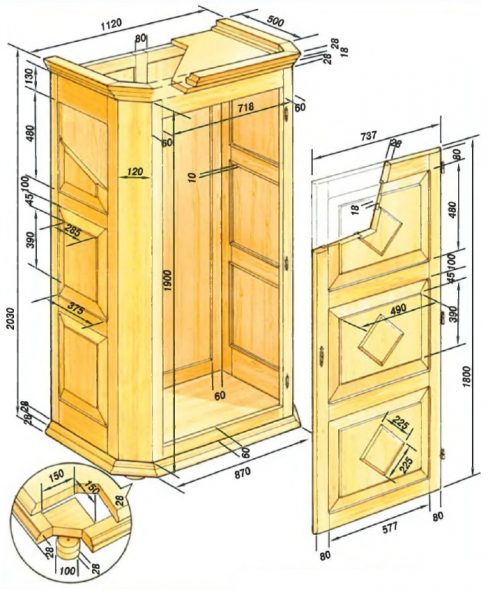

Creating a piece of furniture begins with a careful development of the project. This is another advantage of self-made - the subject, made according to specific dimensions, fits perfectly into the interior, and you do not need to start a permutation. You can make almost any furniture from solid wood - wardrobes in the bedroom, a table in the living room, a cot or a chair on the veranda. You only need to choose the right design or develop your own, and then make a drawing in size.

Draft wooden wardrobe

Materials

Breeds of wood used for making furniture

When choosing a material should take into account the conditions of future operation of the object. If you want the furniture to last for decades, or it will be subjected to constant load (for example, bookshelves in the home library) - it is better to choose solid woods.

- Oak - the most common option for the manufacture of furniture. Oak has a high strength, hardness, it is quite easy to process, very durable. Oak wood is not exposed to moisture, rotting, it also rarely affects bugs and other insects.

You can make any furniture from solid oak, even for wet rooms.

- Beech - in terms of hardness and durability, this wood is comparable to oak. Its disadvantage is the vulnerability to the action of water, so furniture made of beech should not be placed in rooms with high humidity. In the manufacture also necessarily carried out waterproofing treatment using special impregnations.

Furniture made of solid beech wood can be used for structures that must withstand heavy weight.

In addition to these two, most often used materials, ash, rowan, apple, elm, yew, sycamore are also classified as hardwood. Their use is recommended in the manufacture of supporting frames, for example for wardrobes.

The furniture from an ash-tree differs in correctness of lines, originality of drawing.

For structures that are not subjected to heavy loads or, if desired, decorate the furniture with decorative elements, you should take soft wood.

- Pine - the most popular material, due to its low cost, as well as a pleasant bright color. Pine is easy to process, but has low resistance to mechanical damage.

A set of children's furniture from solid pine

- Cedar - suitable for the manufacture of furniture for the kitchen or bathroom, as it is moisture resistant.

Chic wardrobe locker cedarwood

- Birch - soft light wood is very convenient in work, allowing you to create original decorative elements for decoration.

The furniture from solid birch is extraordinarily beautiful, but not too durable and shockproof

Soft wood also includes cherry, alder, maple, poplar, willow, fir.

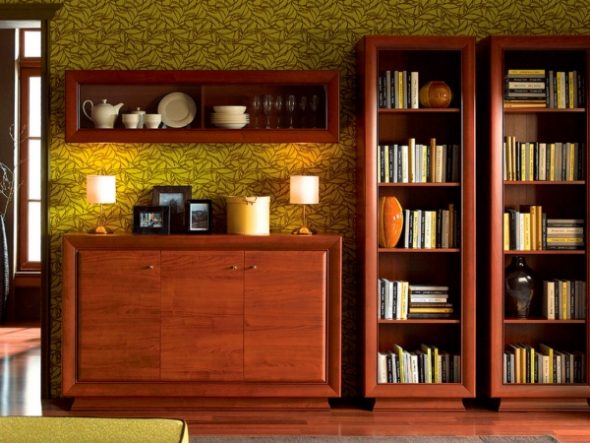

Beautiful cherry wall in the living room

Mahogany, wenge, mahogany - belong to the noble species that have a beautiful wood texture, but are notable for their high cost.

Chic carved mahogany chest of drawers

Instruments

Necessary set of tools for working with wood

To work fit a standard set of tools for wood:

- saw or handsaw;

- jigsaw;

- plane;

- screwdriver;

- hammer;

- screwdriver.

Depending on the project chosen, you will need to find the right fitting - furniture corners, screeds, hinges for doors, handles. All this is sold in hardware stores. There you can also purchase special impregnations, wood paint, varnishes for finishing the product.

Furniture fittings made of wood

Features of manufacturing technology

When deciding to make furniture from an array of their own hands, you must first familiarize yourself with the principle of operation. If it is not possible to consult with an experienced master, video on the Internet will help to disassemble many features. In a professional workshop, the wood is cut using a circular saw, which is quite difficult to install at home.

Circular saw for wood

The parts themselves can be cut with a saw and a construction jigsaw - this solution will be effective when cutting rectangular blanks.

Jigsaw for working with wood

If the project requires details of a complex shape, it is recommended to contact a craftsman or a furniture factory for help, where they will make an even cut exactly according to the drawing.

Finished parts are interconnected in several ways:

- spikes - the product is assembled by cutting through the lugs and spikes corresponding to each other, to connect the parts tightly fit together, glue is sometimes used for greater strength;

Spike coupling parts

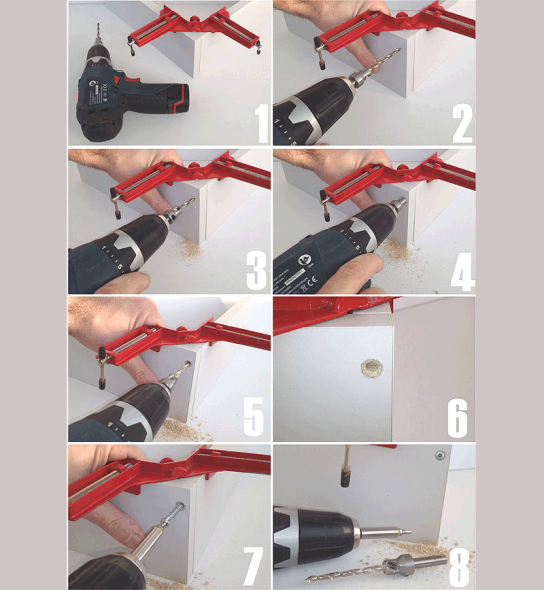

- fasteners - parts are fastened with a screwdriver, screws, accessories are also used - angles, ties.

Connection system Confirmat

A spike connection will require special tools and additional knowledge, so it is recommended to start with a simpler use of fasteners.

Minifix Connector System

Dressing and processing

The saw cut is very beautiful, so you should not paint the interior with this material, it is enough to properly handle it

Decorating furniture from solid wood with your own hands will allow you to give them an individual style, it is better to fit into the general idea of the interior.

Decorative carved facades for furniture made of wood

Most often for the decoration of wooden products used to make carved elements on the facades and doors, sometimes the furniture is decorated with a pattern using a burning out or special paint.

Worktop from solid wood after firing

Finishing the finished product is required not only because of the visual qualities, it also helps to protect the tree from various external influences and ensure a longer service life.First, the surface is ground with special materials (sandpaper, powders).

Wood must be sanded before painting

Then, depending on the chosen breed, the impregnation is carried out by stain or synthetic compositions on water.

Wood treatment with wood stain

Such impregnation will improve the waterproofing properties of the tree, protect it from insects, in some cases - to give it a certain color. The final step is usually the application of varnish or wax, which gives the product an aesthetic appearance and additionally protects the surface.

Covering the surface of furniture with varnish to obtain a protective layer

Video: The secretary (cabinet-table) made of wood with their own hands

50 photo ideas for creating furniture from solid wood with their own hands:

All about the mechanisms of office rocking chairs.

All about the mechanisms of office rocking chairs.

The advantages of creating furniture with their own hands

The advantages of creating furniture with their own hands

DIY furniture making ideas

DIY furniture making ideas

Filling for frameless furniture

Filling for frameless furniture

How to clean furniture from scotch with improvised means

How to clean furniture from scotch with improvised means

Suitable styles for bedroom design with white furniture.

Suitable styles for bedroom design with white furniture.