As caring parents to choose the best mattresses for children

As caring parents to choose the best mattresses for children

Repair spring mattresses do it yourself

All spring mattresses that are on the market can be divided into two large categories - with dependent springs and with independent spring blocks. The principal difference is how they work under load. In the dependent block, the load is distributed between all the springs simultaneously, creating the effect of a hammock. In the independent, each spring works separately, which creates increased comfort.

Mattresses with dependent and independent spring block

Content

How is the mattress

A mattress with dependent springs consists of a metal frame on which springs are mounted, rigidly fastened to each other and constituting a single unit.

Mattress structure with dependent springs

The most common is the spring block Bonnel, invented more than 150 years ago, in which is installed from 120 to 160 springs per square meter. The spring consists of coils of different diameters - maximum along the edges and tapering towards the center. Because of this, they do not rub against each other, do not emit increased noise.

Mattress based on dependent spring block Bonnel

The most common - five-turn steel springs made of hardened wire, less often used four-turn. Dependent spring blocks are used in the production of upholstered furniture - a sofa, an ottoman, and are also produced for the manufacture of mattresses for beds.

This block system consists of spring elements of a special conical shape, which are fastened to each other with a spiral wire made of rigid carbon steel.

This type of mattress is still in great demand among buyers due to its practicality and durability. The cost of this product is 30-40 percent lower than independent spring mattresses.

In the mattress with independent springs, which are called orthopedic, the springs are in covers of non-woven material that are glued together in a single unit.

Bed mattress based on independent spring block

With this scheme, the load is distributed more evenly, which allows the body to take a natural position when sleeping.

In this system, each spring element in the form of a cylinder or “barrel” is in its own special case made of dense fabric or elastic materials.

The orthopedic mattress prevents the occurrence of diseases of the back, the sleeper does not disturb the blood circulation, a person wakes up in the morning rested, without pain.

Independent spring block for orthopedic mattresses

The greater the number of springs used per square meter, the more pronounced the orthopedic effect.

There are 3 types of stiffness:

- high, it is recommended for weight over 95 kg;

- medium weight from 60 to 95 kg;

- soft, weight up to 60 kg.

By the number of springs mattresses are divided into:

- TFK multipack, with the number of springs 250 pcs. per square meter;

- 1000-1000 pcs multipack;

- Multipack S 2000– 1000 pcs.

Types of springs for independent blocks

What is the spring mattress

The composition of the mattress with a block of springs Bonnel

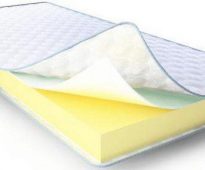

The mattress consists of the following elements:

- spring block;

- base layer of nonwoven material or burlap;

- sealing layer, materials used - thermo-pressed felt, coconut coir, polyurethane foam (foam rubber), stratofiber, latex, highly elastic foam;

- the top layer is a cover made from natural fabrics - linen, cotton.

The composition of the spring mattress with an independent unit

Repair of mattresses with spring blocks

The service life of spring mattresses is 8-15 years. But sooner or later the question arises of its replacement or repair. In some cases, it is preferable to repair the mattress and save 30–40 percent of its cost. What is mattress repair?

Over time, the highest quality mattress loses its properties - dips appear, springs burst, the shape changes, the fabric of the coating wears out and becomes dirty.

In this case, there are two ways - buying a new mattress or repairing an old one.

The easiest way is to go to the mattress waist congress workshop, where the specialists will carry out a comprehensive repair of your product, replace the entire spring block, or, if there are few damaged springs, replace the individual elements. The mattress, which has undergone quality repairs in the workshop, is not inferior in its properties to the newly acquired.

Repair the spring mattress with their own hands

If the spring mattress has become unusable, do not rush to throw it away - try to repair

Possessing skills in repairing a household, having a minimum set of tools, such repairs can be performed independently.

For this work you will need tools.

- Pliers

- Side cutters

- Flat screwdriver

- Hammer

- Furniture stapler with brackets

Materials and consumables necessary for repair:

- springs (can be used from the old unit of similar shape and height);

- lining fabric;

- padding material;

- nails;

- strong cord with a section of 4–6 mm;

- new case.

Stages of repair:

- disassembly of the product;

First you need to disassemble the mattress

- removing the old lining and outdated filler;

- cleaning from dust and dirt;

- inspection and identification of damaged areas;

After that, you need to make a revision of the springs and put them all in the correct position.

- restoration of the frame and spring block;

After all the springs are evenly and firmly fixed to the frame, we tie

Strap is required for strapping.

- control inspection of the unit;

Check whether all the springs are the same length and sheathe the mattress with lining fabric, securing it around the perimeter

- laying a new lining and filler;

- sheathing new case.

We sheathe a mattress with a new cover

The repair of the spring mattress begins with the removal of the old upholstery. This work is best done outside the home, as during operation, a large amount of debris, dust, and decomposed foam crumbs have been formed in it. When disassembling at home, you need to prepare a vacuum cleaner and cover the floor with plastic wrap.

Upon completion of the removal of upholstery filler neatly twists. It can be foam rubber, coconut fiber, batting. Removed lining fabric. After cleaning the frame from old staples, nails, foam rubber and other nonwovens, proceed to the inspection of the spring unit. Checked steel frame, encircling the mattress around the perimeter.

The metal frame, encircling the spring block, can be either one-sided, in less expensive models, or used in furniture production, or on both sides. The unit with a double-sided frame in its performance approaching orthopedic mattresses.

Repair of the spring block

If from the whole array of springs there is not a single broken one, and the central or side part has only slightly slipped, then only sagging elements will change.

Damage to the frame is eliminated, broken springs are removed, new ones are put in their place. Springs are fastened together with a wire.The unit is attached to the base of the wooden slats using fabric belts, staples or nails. Remove all the old fasteners, align the springs on the rack frame and nails or furniture brackets re-fix them. Nails 40-50 mm long should be used. For spring fasteners, nails are hammered at half their length and bent across the coil on both sides. To add extra rigidity to the spring block, it is better to reinforce it with a strong nylon cord. On the perimeter of the wooden base in front of each spring nails are hammered, to which the cord is attached. Rows of springs are alternately fastened with a cord using strapping. First tied up transverse rows, then the longitudinal and diagonally at 45 degrees. At the end of the strapping, nails with a secured cord are bent.

If the place of breakage is a steel frame break, then the joint repair can be performed by welding or, most simply, by packing a copper tube.

Final assembly

The lining material creeps onto the repaired block, the sealing layer is laid, which is fastened with brackets to the wooden base. A cover of dense fabric is stretched on the mattress, leveled and also attached to the base. In the corners, the fabric of the case is folded with a scarf, and a sintepon is placed under the corner to give it a shape.

Repair mattress with independent blocks

Independent springs can also be deformed if used improperly.

After performing disassembly operations, removing the sealing layer should inspect the spring unit.

The most frequently occurring damage is the rupture of the fabric of the spring bags and the violation of the adhesive bond between the covers, tearing the springs from the frame, bending the frame.

When the spring unit is damaged - you need to cut the damaged part, often the middle part of the mattress

After the inspection and detection of damage proceed to eliminate them. The framework is checked, if necessary it is leveled. If broken springs are found, they should be replaced with new ones of the same shape. Worn out bags are replaced.

Cut the size of the spring block of the same height and density with the same number of springs per square meter and insert in place of the old springs

For gluing spring bags it is recommended to use glue gun with rods for gluing fabric. The covers are glued in the center to one third of their length to maintain the orthopedic effect. Upon completion of gluing the springs together, the attachment of the pouches to the frame is checked. In the places of their absence, the springs are attached to the frame with plastic ties or wire. In conclusion, a sealing layer is laid on the block, a cover is put on.

Coconut leaf on the spring block

Foam rubber or natural latex can be laid on a coconut leaf, to give softness, or felt or synthetic winterizer - for rigidity

The mattress repaired independently can last more than 5 years. Repair takes a little time, it is quite capable to be done within one working day. And the work done by hand, will bring satisfaction. Another undoubted advantage is a decent saving of money, which will always be used in any family.

Then a cover is put on the mattress - new or old depending on the condition - and the mattress can be used again.

Video: Repair mattress with independent springs

As caring parents to choose the best mattresses for children

As caring parents to choose the best mattresses for children

Principles of mattress size selection

Principles of mattress size selection

Polyurethane foam mattress: types, design features and advantages

Polyurethane foam mattress: types, design features and advantages