We do a banner of a kitchen corner the hands

We do a banner of a kitchen corner the hands

Postforming countertops - what is it and how to use?

Choose a worktop or kitchen set? Do not know what to prefer among a large number of goods. We offer to pay attention to the postforming countertops. What it is, how it works, how to choose and care. Today you will get answers to these questions.

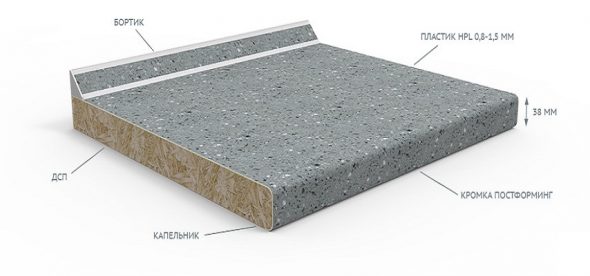

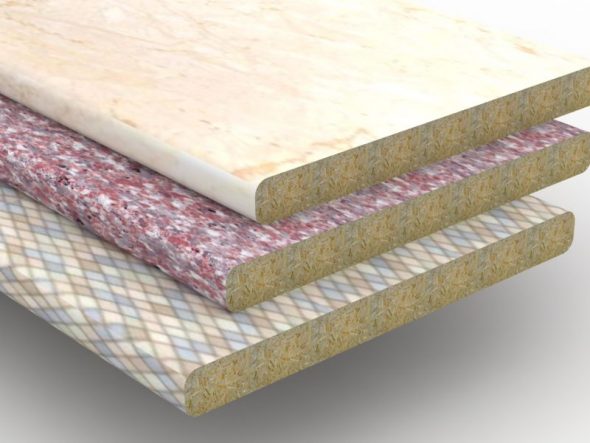

Postforming is a method of cladding the base of a given shape of chipboard or MDF thin paper-laminated plastic

Postforming is a fairly broad concept. It includes a number of products manufactured according to a certain technology. It also refers directly to the manufacturing technology.

Postforming - laminated chipboard

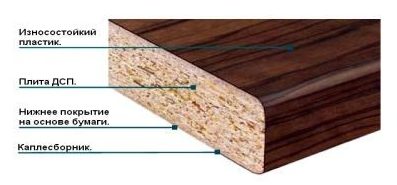

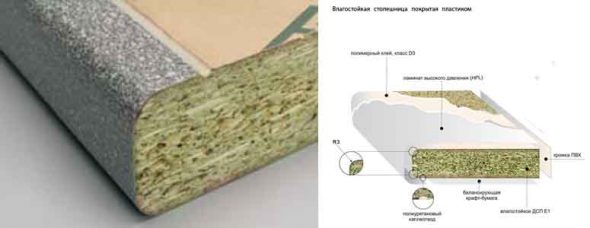

This technology consists in lamination of a table-top or other surfaces from a chipboard or MDF with a thin layer of plastic by heating it to a temperature of 220 degrees. In the process of manufacturing parts on the basis of applied three layers of materials.

- Kraft paper. It is used for strong adhesion of the remaining layers with the base, increases the life of the tabletop.

Kraft paper for bonding layers

- Decorative plastic. It has a color base, contains a drawing or pattern. This allows you to create an interesting design. Often, a pattern is applied to the plastic, which changes slightly during heating, which ensures the unique decor of each product.

Decorative plastics for a beautiful outer side

- The latter is a protective layer. It consists of acrylic and melamine resins. Due to this, the product has a moisture resistance, resistance to high temperatures and high durability.

This technique is quite common today. It was first used in 1976 in Germany. Since it met expectations, and proved the functionality and usefulness quickly spread among companies in other countries.

The most common and popular version of the tabletop is a chipboard tabletop covered with plastic.

Content

Kinds

Countertop postforming that meets the highest requirements for the work surface in the kitchen

Types of tabletops postforming can be divided according to two criteria. Depending on the base used, tabletops are distinguished from:

- DSP;

- MDF.

Material chipboard and MDF in the context

This is wood chip material. They are quite soft, respond well to processing, do not deteriorate during lamination. Materials such as wood, natural stone, granite or marble do not require processing of this type.

Tabletop postforming woodgrain

Top made of chipboard under the stone for a cheap and stylish kitchen option

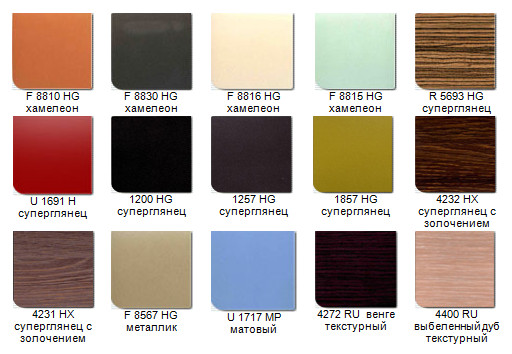

It is also possible to separate products depending on the appearance. You can order countertop postforming.

| View | Production features |

| Under the tree | The effect is achieved thanks to a transparent plastic. In this case, the chipboard plate pattern remains, which is very similar in structure to natural wood. |

| Under the stone | The type of natural stone is achieved through an appropriate pattern of a layer of plastic that is applied to kraft paper. |

| Under granite or marble | Countertops processed using postforming technology are often similar to those made from natural marble, due to the chaotic pattern on the surface. |

This type of treatment has gained popularity, has a beautiful appearance and many more positive aspects.

Moisture resistant marble top postforming

A dark granite chipboard top looks very attractive on a light background.

Advantages and disadvantages

This type of countertops has many advantages, because it is no wonder that it is so popular:

- Price. Compared with other species, this one has a significantly lower price, while with qualities they are very close.

The use in the production of inexpensive materials allows you to form quite a reasonable price for the product.

- Appearance. A bright and brilliant gloss will make any kitchen festive and attractive, and the smoothness of the surface makes cooking pleasant.

Manufacturers offer countertops made from different materials and in different colors.

- Variations of design. Wood, plastic, marble or granite - all in one bottle. With this technology, you can choose a kitchen set for any style, without changing the material and not overpaying,

Variety of plastic coated countertops

The color scheme of tabletops made of thermoplastic coated chipboard

- Strength. Thanks to several layers and a protective coating, such a table has high rates of resistance, and will last a long time.

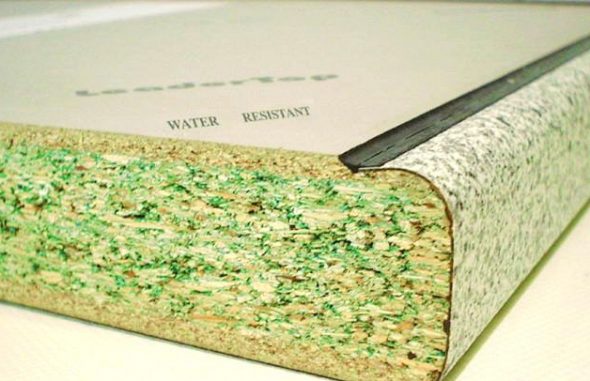

Moisture resistance is achieved by impregnating chipboard with a special water-repellent compound and, in a section, these countertops look greenish

Speaking of flaws, pay attention to the components. Basis - chipboard or MDF. These are not natural bases, in their manufacture formaldehyde resins are used, which can cause an appropriate reaction in allergic people. The coating also consists of synthetic materials and accommodates acrylic or melamine resins. But note that there was no obvious allergic reaction among users. And given that we are mostly surrounded by synthetic materials, this option is quite acceptable.

The use of plastic of inadequate quality can lead to its detachment already in the first months of operation.

Selection rules

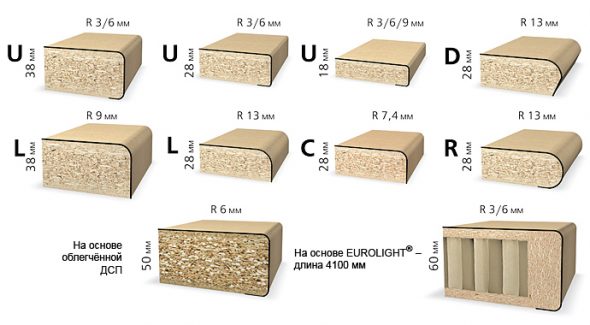

The finish of the butt can be in the color of the tabletop

Finishing the end face in the form of a rounded front edge made using postforming technology

Product thickness and rounding types

It does not matter if you order this product individually or buy it in a store, you should pay attention to some selection criteria.

- Quality. Look carefully at the product: the thickness of the tabletop must match the stated, all other parameters too. Ask the seller for a certificate of quality, and look at those characteristics that you can not see with the naked eye.

Black laminated table top in the interior

- No defects. Sometimes during transportation, small chips or cracks may form on the surface. Therefore, carefully inspect the goods after delivery and selection.

If the surface is damaged, it is almost impossible to restore it.

- Appearance. Besides the fact that it must be in perfect condition, it is necessary that it matches the overall style of the room.

The place of joints of worktops with each other, as well as with the sink and mortise cooking surface must be treated with silicone or sealant that protects chipboard from moisture

Here are the main criteria that can not be ignored when buying a product. Now you can safely go to choose the postforming tabletop.

Care rules

Plastic marbled countertop in mosaic kitchen

For the product to last a long century, it needs proper care. In this case, it is quite simple:

- wipe the table dry after cooking;

- periodically polish the surface.

On the whole, handle the furniture carefully, in order to avoid unnecessary dirt and scratches, which will greatly simplify your work during cleaning.

Video: Production of chipboard tops (HPL plastic) with postforming

We do a banner of a kitchen corner the hands

We do a banner of a kitchen corner the hands

How to cut a hole under the sink in the countertop?

How to cut a hole under the sink in the countertop?

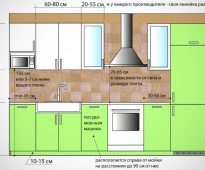

How to make the size of kitchen cabinets (drawings, tips).

How to make the size of kitchen cabinets (drawings, tips).

We do the restoration of the kitchen set with your own hands

We do the restoration of the kitchen set with your own hands

How to assemble a kitchen set. Step-by-step instructions, useful tips and photos

How to assemble a kitchen set. Step-by-step instructions, useful tips and photos

At what height can you hang kitchen cabinets?

At what height can you hang kitchen cabinets?