Colors of kitchen sets. What you need to know about choosing the right shade?

Colors of kitchen sets. What you need to know about choosing the right shade?

How to embed a hood in the cabinet with your own hands

Every year the number of kitchen appliances is growing. Some save time, taking on some of our responsibilities, others make life more comfortable - clean the air, remove steam, unpleasant odor, fumes and grease. These devices include kitchen hoods.

In order for the hood to perform its functions with dignity, it must be properly installed

This equipment is necessary for those who are tired of constantly airing the room, washing kitchen fronts, walls of grease deposited on them. If you are one of these people, then you can not do without a hood. To help you will be numerous shops of home appliances, where you can easily choose a model that is suitable in size, power and price.

This is not all the criteria on which to rely when making your choice. The important role is played by features of use, types, their form, a practicality and productivity, and also external design.

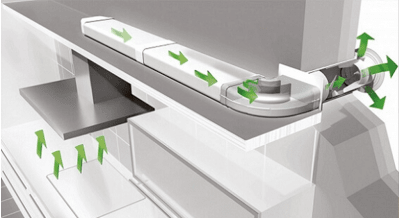

Many devices have a stylish design or hide in hanging furniture

Content

- 1 Types of hoods and their design features

- 2 Built-in hood dimensions

- 3 Installation of built-in hood. Required materials and tools

- 4 Work with the bottom shelf of the cabinet

- 5 Transformation of the middle part of the cabinet

- 6 We build the hood into the cabinet and install the air duct

- 7 Video: Installing a built-in hood

Types of hoods and their design features

A variety of air filtering kitchen appliances

Before buying equipment, you should decide on the place where the stove will be located, since the hood is installed above it. The design features of the model depend on the place of installation of the plate. According to the type of location of the kitchen area, the hoods are divided into several types.

- Flat. It has a small size, does not require installation of the duct. It has built-in filters through which polluted air passes. The inconvenience is that they need to be changed periodically. The service life of the filter depends on the intensity of use of the stove and hood.

Flat hood is an inexpensive option with integrated filters that takes up little space.

- Dome. Equipment of this group, connected to ventilation, has high performance. A more impressive case size makes it possible to install larger fans than flat ones. Therefore, they are used in spacious rooms where there is a need to filter a large stream of air from the kitchen. Clear the smell in the far corners of the room.

Dome or chimney hood has good aerodynamics, works almost silently, but costs more

- Built. The most widely used species. The main advantage is that it hides in the kitchen furniture or countertop and does not spoil the overall style of the interior. Another plus is that the installation of the built-in hood in the headset cabinet is easily carried out independently and there is no need to call the paid master.

Built-in hood is the most optimal solution for small spaces.

Which type of hood to use depends on the size of your kitchen. If the kitchen is small, then the power of a flat hood will be quite enough. Built-in models are good in typical Khrushchev. They save space, since the air duct and the frame itself is neatly placed in the closet. In the kitchen, where space allows, there is a detached island, there is a fireplace or dome hood that fits perfectly.

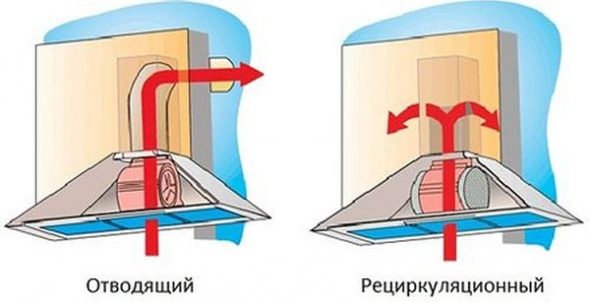

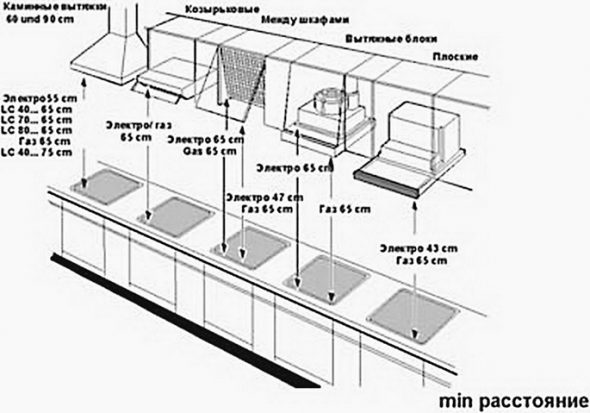

The scheme of the kitchen hoods

Built-in hood dimensions

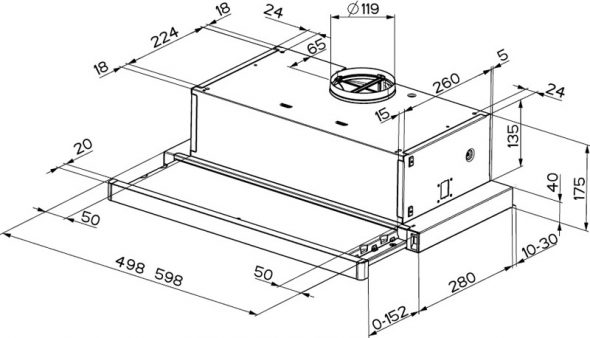

Exhaust scheme with sliding block with detailed dimensions

In order to properly install the built-in hood, make measurements of the plate, the existing cabinet, which will be built equipment. If you do not pay attention to this, it may happen that the size of the device will exceed the size of the cabinet.

Parameters for installing the exhaust height

Then it will be necessary to carry out additional manipulations with it - to change the walls of neighboring cabinets or to make a new box, to the dimensions of the hood. Properly choosing a model for the kitchen that fits inside, master the installation yourself, without the help of specialists.

The most common option is a built-in hood 60 cm

The body of the majority of built-in hoods, has a rectangular shape, which greatly facilitates installation. The width of the devices is different. There are compact options, from 45 to 50 cm, which fit into standard kitchen units.

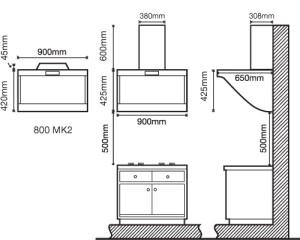

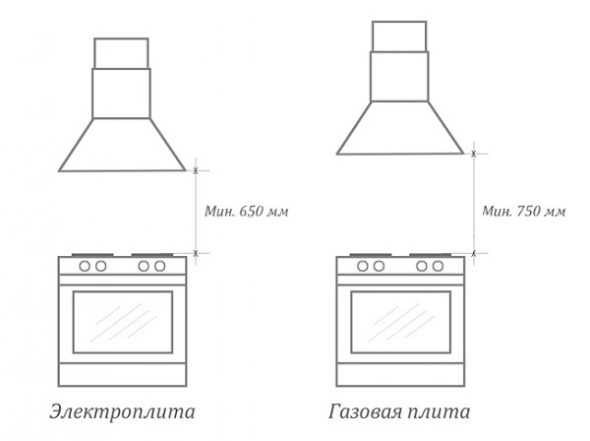

Another important point that must be considered: the distance from the plate to the hood. It must be such that parts of the appliance are at a safe distance from the heat of the stove. Placing high from the hob is impractical, performance will be significantly reduced. Steam with the smell of cooked food is badly drawn in by the device, there will not be the necessary efficiency.

In the instructions for the device you will always find the recommended centimeters, the average indicators for all devices are as follows:

- for electric cookers - from 65 cm to 70 cm will be optimal;

- for gas - from 70 cm to 80 cm, since there is an open fire.

The distance from the gas stove and electric stove to exhaust

The size of the plate also matters. The width of the equipment, ideally, should match or be 1-2 cm wider than the hob. This will ensure maximum installation efficiency, and if it is smaller than the plate, then some of the air will not be trapped, and this will reduce productivity.

Recommended distance from the stove to various types of hoods

Installation of built-in hood. Required materials and tools

Proper installation of the kitchen hood

Consider the option when you decide that you do not need to make a new box, it only remains to retrofit an existing wall cabinet. Before proceeding with the installation, it is necessary to determine the material from which the vent will be made, to prepare the necessary tools so that everything is at hand.

Types of materials from which the duct is most often formed.

- Plastic. Rectangular or round shape, different size and diameter. The rectangular channel takes up less space and this is its advantage. This type of duct has smooth walls, so that the air flow is higher, the dirt particles are less deposited on a smooth surface. The downside is that additional knees will be required for installation. The joint should be covered with sealant.

Plastic duct for connection to the hood

- Corrugated. Easily accepts the desired angle of inclination. Extra knees will not be required. To avoid excessive noise, the corrugation should be well stretched. In order that passability of air did not decrease, the angle of bending should not be more than 90 degrees. Excessive bending causes poor draw performance. If necessary, from a round shape to make a rectangular, then it is easy to implement by pressing your fingers.

Corrugated duct for exhaust, hidden behind the panel

Both types have a number of pros and cons. What to choose, you decide on the basis of the parameters of the equipment, the capacity of the cabinet, your preferences.

The construction of flat rectangular pipes can be hidden in the suspended ceiling, almost without taking away the height of the room

For the work is useful next tool. For marking and measurements need a tape measure, a square, a pencil.For cutting holes - jigsaw, files for wood. Another useful screwdriver, bolts, screws. For gluing joints, get glue-sealant. To strengthen the tightness using clamps, they need to be prepared.

Tools for installing and connecting hoods

Work with the bottom shelf of the cabinet

Preparation of the kitchen cabinet for the installation of built-in hood

When installing the built-in hood in the cabinet, you can go several ways.

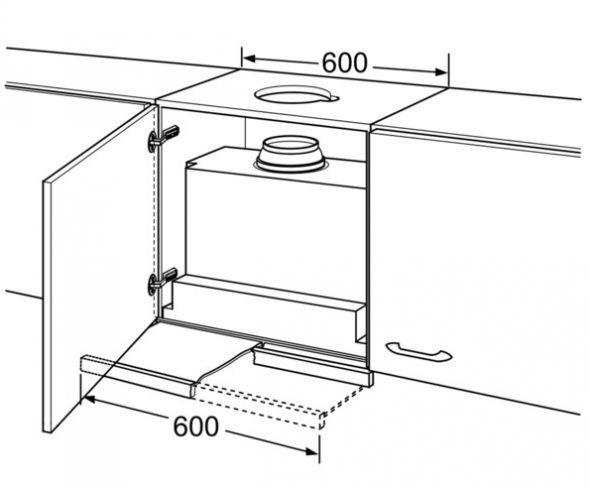

- Order a kitchen cabinet, already without a bottom. To output the duct you will need to make corresponding holes in the middle shelf and the top.

- Make a cabinet under the hood with their own hands, based on the size.

- To alter an existing furniture object, first remove the bottom or cut a hole, according to the dimensions available.

Disassemble the cabinet is not required. It is necessary to remove it from the wall, disconnect the door. It will be more convenient to perform your actions on the floor. "Screw" the back wall, unscrew the side fasteners, then the bottom shelf will easily go away itself.

When you cut out a place for exhaust, it is necessary to make it so that the device body fits tightly to the front wall, and not vice versa. Place where you will cut, mark with a marker, drill holes in the corners of the basting, and then cut through.

Transformation of the middle part of the cabinet

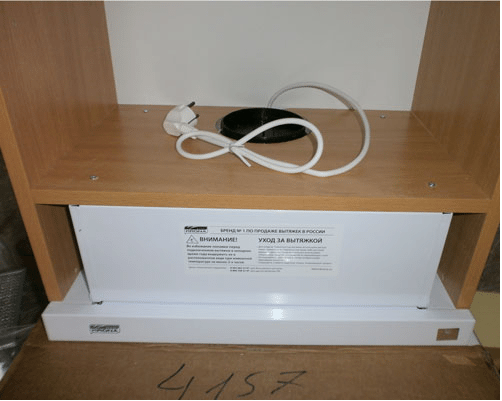

In the shelves of the cabinet will have to cut holes for the duct

Most often, the hood is attached to the middle shelf. Therefore, it also needs to make a cutout under the duct. Mark the cut with a pencil, if it is round, drill a hole with a diameter of 10 mm to enter the file and cut it along the mark.

Then it is necessary to outline the attachment points of the device to the middle part. Attach the shelf to the device, with a sharp object to make a notch in the future location of the screws.

Example of mounting the hood to the wall

To fix the shelves to the sides, use plastic corners. First, four corners are attached to the shelf; we adjust its position by placing the box on the floor.

The output of the power cord above the hood, as well as the organization of the holes for the corrugated pipe

We build the hood into the cabinet and install the air duct

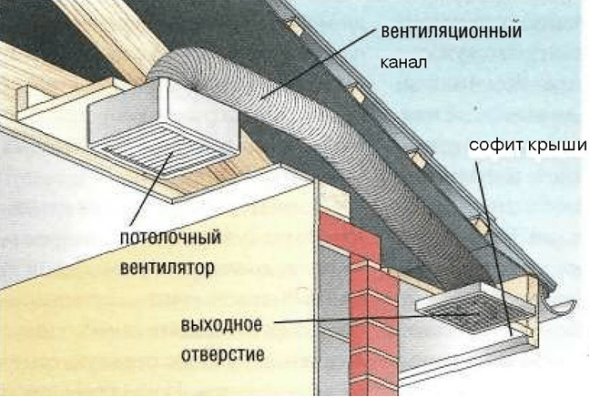

Ceiling ventilation installation option

The penultimate stage of work will be the connection of all parts. The cabinet with the middle part and the hood attached to it is hung into place. Do not forget that the retractable part of the equipment must move freely back and forth. In this part is a filter that traps fat. It starts working when the movable part is located above the slab.

Installing the duct on the top of the cabinet

The last stage - the installation of the duct. It is inserted through the top of the cabinet, into the hole that was previously sawn through, and connected to the device. Joints are necessarily coated with glue, fastened with clamps. It is also important to keep the possibility of detaching parts for cleaning the system from dirt.

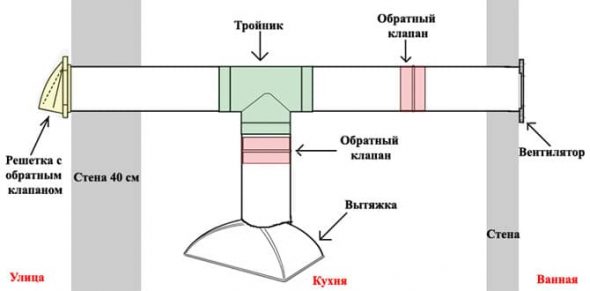

Then the air duct is connected to the ventilation. For mounting using special grilles. An exhaust hood is an electrical appliance; a socket with ground connection should be located close to it.

Duct connection to the ventilation duct

The work is quite simple, given the points described above. Built-in hood - a good option for those who want to save space, keep a beautiful interior.

An example of mounting the hood in the cabinet above the hob

Video: Installing a built-in hood

Colors of kitchen sets. What you need to know about choosing the right shade?

Colors of kitchen sets. What you need to know about choosing the right shade?

Everything is at hand: the correct filling for kitchen cabinets

Everything is at hand: the correct filling for kitchen cabinets

How to choose the shelves suitable for the kitchen?

How to choose the shelves suitable for the kitchen?

Choose the design of kitchen set: technical equipment and facade

Choose the design of kitchen set: technical equipment and facade

How to make a DIY do-it-yourself buffet

How to make a DIY do-it-yourself buffet

What material is better to choose a kitchen?

What material is better to choose a kitchen?