How to assemble a kitchen set. Step-by-step instructions, useful tips and photos

How to assemble a kitchen set. Step-by-step instructions, useful tips and photos

How to make a wood countertop with their own hands

Having created a tabletop with your own hands, you will receive an exclusive, absolutely unique thing, ideally suited for a set. You will be absolutely sure of the quality and strength of the product. Using your own materials, create an environmentally friendly product.

The tree in the kitchen looks presentable and gives the kitchen a highlight.

Content [Hide]

We determine the design and construction

Wooden tabletop combines with almost all styles.

People spend most of their time at home in the kitchen. In the kitchen space in the morning our day begins. Beautiful, well-chosen, well-established table top hands brings comfort, creating a good mood for the whole day.

Types of kitchen countertops made of wood

It can have a different design, it can be glued, assembled from wood plates or made from a single piece.

Glued beech wood table top

The most practical and durable option is a solid wood table top made by hand. Wooden countertops look more aesthetic than plastic, glass counterparts. The natural pattern of the tree is individual, unique.

Exclusive solid wood table top

The main condition for the proper design of the kitchen is well-chosen size of the countertop.

The size directly depends on the area of the room, and, of course, on the purpose of the product itself.

For a family of four, the worktop is best suited for a dining table measuring 100 * 100 centimeters.

Table from a natural beech with a square folding table-top

The height can vary in the range of 70-90 centimeters, it directly depends on the height and size of the owner of the kitchen.

Reliable, durable and secure natural wood table top for the kitchen table

Necessary materials

Wooden countertops are the best choice. Products are easy to process and look rich, representative. It is important that wood is resistant to external influences. Scratches appear much less frequently than on plastic or glass. If the kitchen worktop has lost its presentable appearance due to prolonged use, it can be easily restored and given a second chance to serve further.

Materials and preparations for kitchen wooden worktops

Usually wood is any material containing wood. This is a chipboard, decorative sheets made of wood of different thickness, but clearly, the best material for the countertop will be a solid piece of wood.

The first most important point in the manufacture of wooden countertops is the right choice of material. A certain type of wood has distinctive features. Soft rocks in the process of making the tabletop should not be used. A tabletop is a place in the kitchen where we constantly cut, we prick, chop and beat something. It is better to stop the choice on hard wood. It is preferable to use the following proposed breed.

- Oak - the most practical breed for the manufacture of countertops. It has all the necessary qualities. The material has hardness, strength. It has a variety of colors.

Beautiful and sturdy beech wood window top

- Walnut - not inferior to the strength of the oak, has a beautiful, original texture. It has a high decorative value.

Kitchen island countertop solid walnut

- Ash - is a strong, flexible, non-brittle type of wood. It has a rich color range. Use mainly its natural colors without additional toning.

Ash wood table top - a product made from modern natural material, giving a special comfort to any interior

- Beech - durable, elastic. It has a beautiful light color texture.

Original kitchen island with beech wood top

An interesting decision to make a product from several wood species. In this case, the tabletop with the proper selection of rocks, looks rich, interesting, original.

Before starting work, the material must be dried, treated with special compounds that protect the wood from excess moisture and insect damage.

Impregnation and protective compositions for wood

Required Tools

Tools that may be needed for the manufacture of countertops

If there is a desire to make a wooden tabletop, there is a design project and specially selected material, we determine the list of necessary tools. This is a jointer, handsaw, mill, drill, hammer, pencil, tape measure, glue, varnish, antiseptic.

Making wood panel

We select dry boards of one thickness

Making a carpentry shield - is the arrangement of pre-prepared elements. The main details of the wood panel are wooden boards. But first, they must be specially processed.

Cutting boards of the required size

We process the surface of all boards with a planer and jointer

Level the surface of the board material with a plane. Sandpaper carefully polished surface. After grinding, the prepared material must be treated with an antiseptic.

Grind with sandpaper sludge sander

They have a huge selection in hardware stores, but note that you need a solution for interior work. Antiseptic protects the tree from the excess moisture, in excess of the existing kitchen, will prevent the occurrence of mold and insects.

You can connect parts together in several ways.

Gluing boards under the tabletop

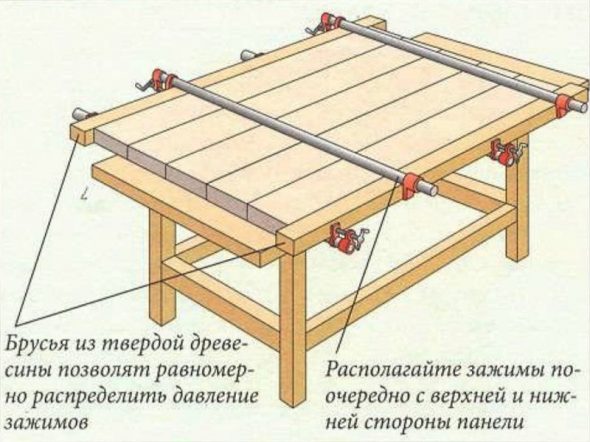

Clamps for gluing individual boards into one tabletop

Edging is the easiest, but note the most unreliable mounting method. Suitable for making products of small sizes with a minimum load. With short-term use, the surface of the tabletop will be covered with small cracks, and in the future such a product can simply crumble.

Using an electric jigsaw, in the side ends of the blanks, we cut the grooves with a depth of about 1 cm

Thorn-groove technology - this solution is more acceptable for joining tabletop parts, but if durability is an important element for you, then we strongly recommend using the following board mounting option.

In the grooves of half of the boards, glue the mounting rail, then connect the boards with the slats with those that have free slots

The groove-comb method gives the most stable result. He is well known to those involved in the assembly of the race or the installation of wooden flooring.

Edge-groove connection

Ways of joining wooden parts in joinery

If the master does not have special equipment at home, it is difficult to make smooth edges. Do not get upset in advance. It is necessary to contact the specialists, they will process the material on a milling machine.

Note that the depth of the grooves should be 10-12 centimeters; when using a thin board, the depth of the grooves is reduced to 6-7 centimeters.

Now the boards are fully ready to assemble the finished product. Boards are divided into two types. The first board has a groove, the second rail. It is necessary to fit the groove tightly with the rail. Boards firmly glued together. We get a solid tabletop.

The resulting finished canvas must be sanded, coated with a primer and coated with decorative varnish. Make the opening varnish better in several layers.

The color of the surface of the product, if desired, can be changed. Surface tinted stain on the tree under any shade. Do this before coating the product with varnish. It must be remembered, after varnishing the tree has the ability to change the original color, it becomes darker.

Wood stain

Installation

Fastening the wooden tabletop

The table top is fully prepared, ready for installation. First you need to install the lower parts of the cabinets on the place of permanent location. Care is needed, there is no room for error, otherwise we will spoil the product. Required accuracy in the calculations. The cabinet under the sink should be located near the sewer drain, the surface of the stove should be located in the immediate vicinity of the gas pipe. Be sure to consider the location of the outlets. We smear the tops of the cabinets, the ends of the previously acquired wood glue. We put the tabletop on top of the cabinets, fasten with screws or screws. Now the top panel is firmly fixed. A small gap formed between the surface and the wall must be closed with furniture plinth. The edges of the installed slats are covered with caps.

To serve a wooden tabletop for a long time, you need to carefully take care of it.

Video: How to make a tabletop of wood. How to make a tabletop.

Photo gallery of beautiful kitchen worktops made of wood:

How to assemble a kitchen set. Step-by-step instructions, useful tips and photos

How to assemble a kitchen set. Step-by-step instructions, useful tips and photos

How to arrange furniture in the kitchen

How to arrange furniture in the kitchen

How to choose the kitchen countertop

How to choose the kitchen countertop

At what height can you hang kitchen cabinets?

At what height can you hang kitchen cabinets?

Kitchen drawers: types, advantages and features of choice

Kitchen drawers: types, advantages and features of choice

Choosing kitchen tables and chairs for a small kitchen

Choosing kitchen tables and chairs for a small kitchen