Features, pros and cons of bunk beds for children

Features, pros and cons of bunk beds for children

The benefits of creating a folding bed do it yourself

Nowadays, the theme of comfortable home furnishing is actively gaining momentum. In the market of furniture solutions begins to prevail more compact and stylish set. The reason for this trend is the glut of the market, and, accordingly, of our apartments, with various products, household items and furniture that almost do not crowd out their owners.

A folding bed is a guarantee of saving a large amount of free space in the room!

Not a rare case when your room or bedroom does not allow to fit a large dressing table or a wide double bed. But what if you try to combine in one solution two or more furniture components?

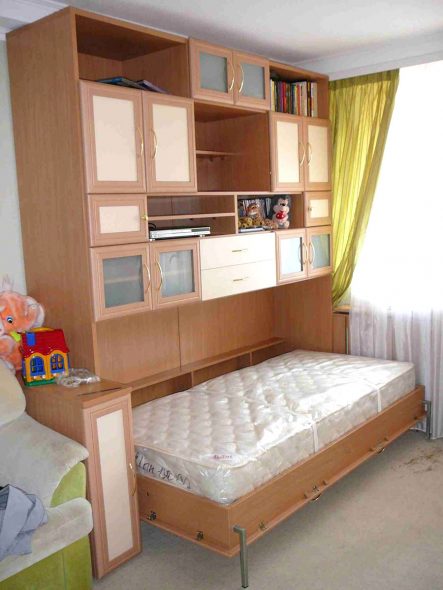

Convenient combination of wardrobe and bed in a single set.

A folding bed is not new in the market of furniture services. Numerous modifications from different manufacturers have filled their niche to capacity. But the price of compactness and manufacturability is by no means small, and besides, all the whims and wishes of the client will not always be taken into account.

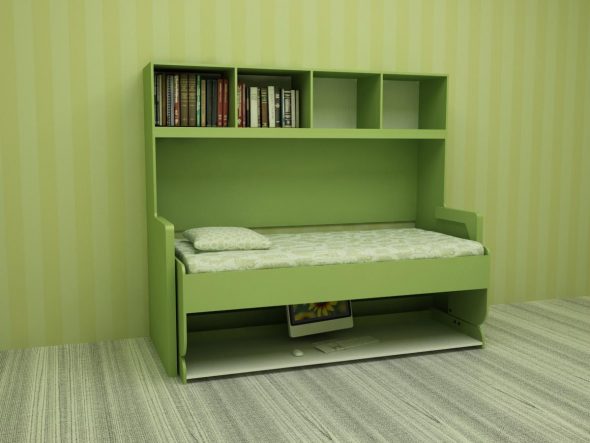

This version of the single bed can easily fit even in a very small room.

If you want to save your wallet from unnecessary expenses and do not turn your home into a cluttered warehouse, a folding bed with your own hands is your option.

The bed built into the wall will allow you to save all free space competently and with taste even in a very small room.

The advantages of self-assembly of such a bed are obvious:

- reducing the cost of the product by 2, 3 times in contrast to the store counterparts;

- universal design that takes into account all your needs;

- use of known high-quality materials.

Options for the operation of a folding bed.

The assembly does not require you to special construction or engineering skills. It is enough to adhere to all instructions and have minimal experience in assembling fittings to bring this matter to the final result. Prepare all the necessary tools and drawings for more productive work.

Most often the folding bed is used together with a spacious wardrobe.

A few general comments:

- work should be carried out on a flat surface;

- Do not forget about the means of individual security;

- at each stage of assembly, check the perpendicularity of the corners using a square;

- use quality, intact lumber;

- proceed to making the bed only after studying the drawings.

The assembly of the bed should be carried out only after a clear study of the drawings.

Content

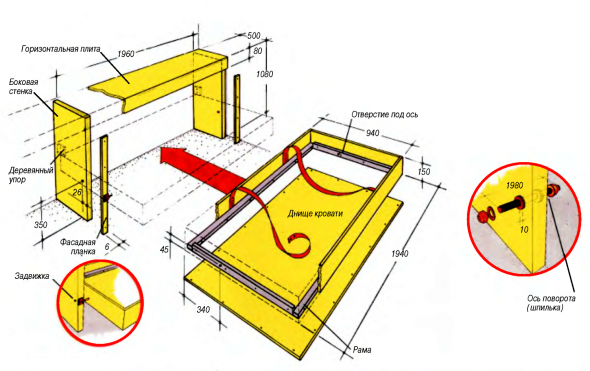

Design and construction of the bed with the necessary drawings

There are many models of similar beds-transformers. But a folding bed with your own hands, the drawings of which you only have - this is already a unique exclusive and a highlight of your interior. You design it yourself, starting from the size of the bedroom.

The stylish folding bed will easily fit into any interior of the apartment

Such furniture is perfectly complemented by various dressing tables, dressers, drawers or ordinary shelves, technologically built into the design of the cabinet.For the individual style is responsible for a diverse decor - with this element are determined last.

The design of the cabinet, which hides a folding bed

The standard configuration of such models includes the following components:

- cabinet frame;

- bed base;

- lifting mechanism;

- elements of decor.

Even children can disassemble and assemble a folding bed.

Simple, at first glance, the design carries a number of strength requirements that directly affect the geometric appearance of the product. Therefore, starting from the size of the bed, the cabinet frame is projected and the force of the power device is determined.

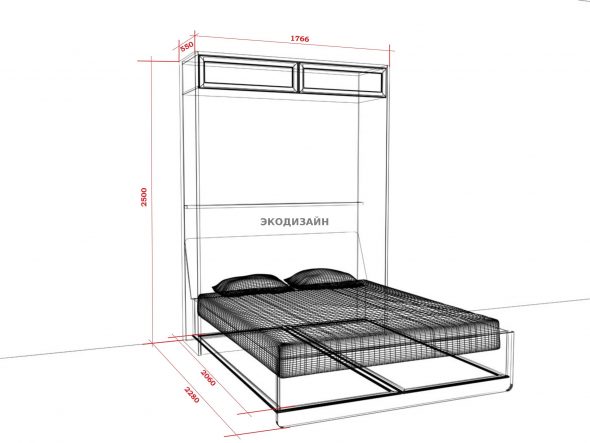

Standard parameters of a folding bed

All required dimensions are displayed on the drawings - overall and assembly. Especially important is the drawing of the installation of the power element, which is the most important part of our bed. You should also pay attention to the cutting panels (if you are cutting the material yourself) and the display on the drawings of the main mounting points.

Option folding bed on the podium

Necessary materials

The material for the cabinet and base can be chosen according to your taste and color, the main thing is to take into account, when determining the thickness of the workpiece, all the loads. It is recommended to use ordinary chipboard - not picky in use material that will meet all the strength requirements and preserve the durability of your mattress. The following dimensions are taken from the calculation for a single berth.

Single bed built into the wall with plenty of storage space.

So, we will need:

- 2300x400x25 - 2 pcs., Side panels of the cabinet;

- 1700x400x25 - 2 pcs., The upper and lower panels of the cabinet;

- 1700x150x25 - 2 pieces, reinforcing partitions for the frame;

- 2050x150x25 - 2 pcs., Side panels of the bed base;

- 1620x150x25 - 2 pcs., Bottom and headboard for bed base;

- 1700х2300х15– front panel;

- lifting mechanism - 2 pcs. (it is better to purchase it in a specialized shop, knowingly specifying the necessary effort to raise the bed and fix it in the right position).

The option of reliable fastening, due to which the operation of a folding bed will be much longer and more fruitful.

Necessary accessories:

- Euro screws 5x70 - 30 pcs .;

- 4x12 screws;

- 4x22 screws;

- corners of 20х20 mm, 10 pieces. (furniture);

- corners reinforced 60x60, metal;

- anchor fasteners 10x80 mm;

- powerful magnetic latch for fixing the bed in the raised position;

- hidden legs for a bed;

- decorative elements of decoration of facades.

You can choose the version of the legs for a folding bed that will fit best.

Necessary tool

- roulette;

- angle with a ruler;

- level, length from half a meter;

- pencil;

- fine sandpaper;

- adjustable wrench;

- perforator with a minimum drill diameter of 10 mm;

- wood drills 5 and 8 mm;

- screwdriver;

- protective glasses;

- jigsaw.

A folding bed can be easily transformed into a comfortable sofa.

Step 1: assembly of the frame and the power elements of the box

Align the walls and floor before starting the assembly - the maximum deviations should not exceed 5 mm per meter of length. The process begins with the manufacture of boxes. Since the side panels are overhead, they are drilled in a plane with a diameter of 8 mm.

Drawing of a single folding bed

The remaining elements of the box are internal, and, accordingly, are drilled into the end. The whole box is covered with euro screws. For the perception of the load that occurs when raising and lowering the bed, two stiffeners will suffice. They should be located at a distance of 700 mm from the base and top. There is also an option with built-in shelves inside the cabinet, which can also act as reinforcing elements. Having carefully laid out and fixed on the side panels of the fixed parts of the lifting device, do not forget to check the design for mutual perpendicularity.

If you make a folding bed with your own hands turned out to be difficult for you, then at any time you can order this option of furniture to order.

Step 2: Build the bed base

When designing a cabinet, they are usually repelled by the size of the bed, and it, in turn, is the size of the mattress. Using the corners and screws 4x22, we collect two side walls and two backs in one frame.Front panel fasten screws 4x12 on the furniture corners.

Choose high-quality materials for your folding bed that will provide her with a stylish look.

In this case, there is one important nuance — You need to start fixing the wall on 4 corners, and only then, aligning on all sides, fix completely. Thus, possible distortion is excluded. At the head of the head, having previously marked it, secure the reciprocal movable part of the lifting mechanism. To secure the mattress on the bed, use durable straps.

Folding bed transforming into a sofa.

Step 3: the stage of installation of the box and fixing the power mechanism

Install the box on a flat floor or on wooden bars. In the place of installation of the frame we cut off the plinth. It is necessary to fix the box only on a strong concrete wall. The axis of rotation of the mechanism and the upper horizontal line are selected for the base. Here we use only reinforced corners and anchor bolts, since in these places the main efforts will be perceived.

Wood is often used as a material for the manufacture of a folding bed.

The connection of the box and the bed occurs by docking mating power devices. For proper operation of the structure, namely, its fixation in any position, it is recommended to use a force mechanism based on a gas spring.

Simple design folding bed, made their own hands.

At this stage, the work is almost completed, and you can be proud of such an achievement as a bed with your own hands. The folding system is installed and functions perfectly. Secure the mattress with strong straps.

Small children's folding bed, easily turns into a working area with a comfortable table.

The final stage - decorating

The façade of the final product is often decorated with false-doors - the invoice element, which is part of the decoration on which the handles are attached. In no case do not use mirrors in such beds, as they are not designed for such loads and may soon crack.

Even the simplest design of a folding bed can fit into any room interior.

It will also affect the weight of the lifted structure, which may affect the durability of the mechanism. Do not forget to install the legs in the pre-drilled holes and magnetic latches. Now the work is completed, and the new decoration of your interior is completely ready for your holiday.

A single folding bed can be equipped with a forehead room, and no one else will even think about its presence, since it will be disguised as a closet.

VIDEO: How to make a folding bed with your own hands

50 photos of folding bed design ideas:

Features, pros and cons of bunk beds for children

Features, pros and cons of bunk beds for children

Bed attic "Kid" - an indispensable attribute of the children's room

Bed attic "Kid" - an indispensable attribute of the children's room

Features and benefits of a metal bunk bed

Features and benefits of a metal bunk bed

IKEA bunk bed

IKEA bunk bed

Features bunk beds-transformers

Features bunk beds-transformers

We make a mattress with our own hands: foam rubber, orthopedic, pillow

We make a mattress with our own hands: foam rubber, orthopedic, pillow