A bed with a soft headboard is an excellent solution in the design of the apartment

A bed with a soft headboard is an excellent solution in the design of the apartment

How to make slats for a bed with your own hands

For beds, slats can be made exclusively of wood. Most often used birch and poplar. This material is chosen for its flexibility and resilience. Wood also contributes to excellent ventilation of the mattress.

Double bed with slats - the perfect orthopedic version of the bed.

Experts believe that 30 beds are enough for a double bed, a single bed is several times smaller. Manufacturers do not adhere to this opinion and place 20-22 pieces. But if you decide to make slats and a bed with your own hands, you can independently calculate their number.

Option of a double bed with a standard set of slats.

The advantages of making furniture with their own hands

Among the advantages of self-construction of the bed and slats, the following factors are noted.

- Environmental friendliness. Natural material, that is, wood, will not be able to adversely affect human health.

- Durability. A hand-made product will last for many years. The bed can withstand a large load, which confirms its strength.

- Individual size and design. The bed with your own hands will be made according to your drawings. Its size, shape, you can adjust to the desired parameters. Do not have to look for a place to accommodate a large bed.

- Saving. This applies not only to the space in the room, but also cash. You independently count the amount of material needed, and acquire them. It will be much cheaper than buying an already finished product in a store.

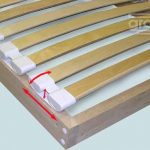

The option of self-installation lamley

Content

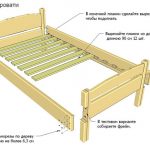

Bed design and construction

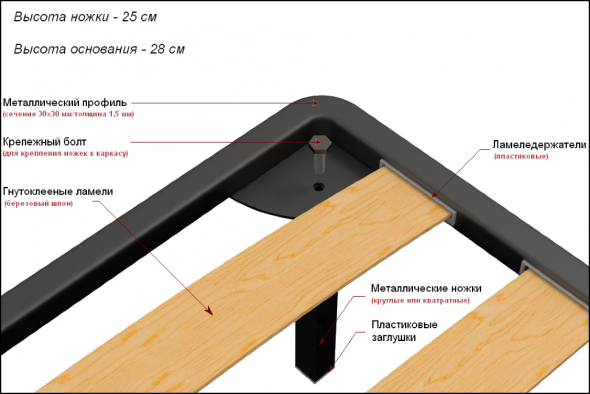

The designs of single or double wood beds are quite similar and quite simple. Both types of furniture consist of the following parts.

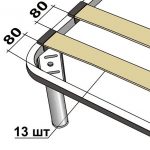

Durable metal-mounted lamellae, self-installed.

- The mattress, on which the person will sleep, is placed on a flat base or slat. For the first option, use a thick sheet of plywood. Slats are transverse slats. This design is preferred. On it the mattress will not be deformed, the strips themselves are quite elastic. This design is more comfortable for sleeping.

- Slats or plywood are located on a frame made of high-strength bars.

- Side panels or legs can be used as a support to which the frame is attached.

Slats are a strong orthopedic base for beds.

Choosing the size of the future bed, it is recommended to rely on the parameters of the mattress. Also consider the location and location of the product. Standard size single bed - 200-210 cm long and 90-100 width. In the double, the length remains the same, and the width is 180-200 cm, that is, doubled.

Standard bed slats.

The height of the product is a rather subjective parameter. It all depends on your preferences.

Purpose of the cross bar

It has already been noted that a thick sheet of plywood can be used instead of a cross bar.It is worth noting the advantages and purpose of the lattice to understand that it is preferable.

Selection of the type of attachment for slats in the base of the bed.

- Reducing the load on the bed. Due to this, the quality of the product is enhanced, the service life is increased.

- It has the quality of the spring. The plank is elastic and therefore all the load that acts on it is distributed evenly.

- In the dream, your spine will assume the correct position.

- The grille is fastened with special holders. This allows you to make the design reliable and avoid later squeaks and noise.

- The level is located in such a way that natural ventilation of the bed can be made from all sides.

The process of creating the base and frame beds of slats

Necessary materials

Before you buy everything you need and do the bed with your own hands, as well as the slats, you should complete a detailed drawing. For a double bed standard parameters will require the following materials.

The process of distributing lamellae along the base of a single bed.

- 3 boards with dimensions of 200x30x3 cm. They will become the walls and headboard of the product.

- 2 boards with dimensions of 250x30x2 cm. They will become the side parts of the bed.

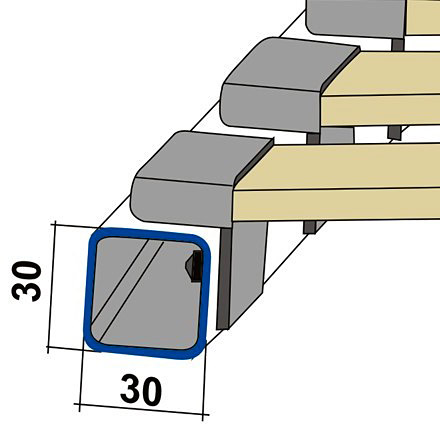

- 5 bars, each 200 cm long, section 4x4. Need for the manufacture of the supporting structure, support and legs.

- Rack size 150x4x2 cm. It will become a cross bar at the base of the bed. Rake is needed to secure the headboard boards.

- Stain

- Joiner's glue.

- Luck;

- Screws.

Lamella can be fastened, both with the help of fasteners, and when using self-tapping screws.

It is worth once again to clarify that the amount of material indicated for a double bed standard. You should select everything in accordance with the parameters of the future product and drawings.

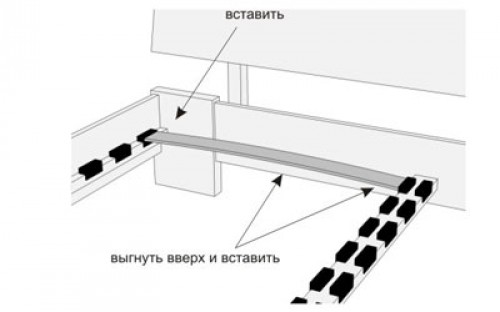

How to insert the slats in the mount.

Required Tools

For self-assembly of the bed and the manufacture of the cross bar you will need a drill, cutter, sandpaper. Also prepare a hacksaw, a pencil. For measurement and accuracy will be useful rulers, roulette, square. Among the tools needed for self-manufacturing beds should be a plane, screwdriver and jigsaw.

Installing slats in the bed base can be done independently, it does not require some expensive equipment.

Manufacturing process

After acquiring the required materials and preparing the tools, you should proceed to marking and further cutting them. It is recommended to adhere to the following rules in this process.

The ideal method of fastening slats with metal fasteners.

- Make a detailed drawing of the future bed, specifying all the exact parameters.

- Write a list of all the parts that are needed for the product. Indicate how much material is required for each of them.

- The markup, in the places of future cuts, is recommended to be done using a cutter or a pencil and necessarily a ruler.

- Making parts identical in parameters in several copies, it is necessary to make one and leave it as a template. This will facilitate and speed up the process.

- Spilov places should always be cleaned with sandpaper.

Ortho-frame for the crib

After marking, you can proceed to the construction of the frame.

It is recommended to start the assembly by measuring the parameters of the mattress that will be used on this bed. In the frame of the frame, he falls freely.

Slats are increasingly used for a perfect and durable base for beds.

Using the removed parameters, saw off 2 front and long boards, which will become sidewalls.

Reinforced block lamellae for high-quality base beds with a high degree of load.

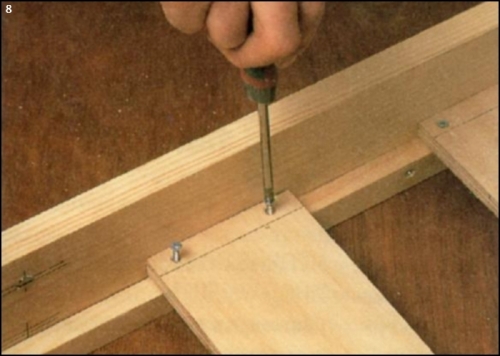

Collect the obtained parts in a rectangle. To fasten them together you can use wooden spikes or eyelets. Holes cut with a jigsaw. You can gouge chisel.

Orthopedic base adjustment

The received eyes are greased with glue and connected. Align everything to a 90 degree angle and, using clamps, fix until completely dry.

Select the type of fastening of the slats, which will be the most durable and reliable.

The frame is ready. It is quite reliable and strong. To assemble the base of a wooden bed was an easy process, you should connect the parts with self-tapping screws, which have an additional mount, and metal corners.

Orthopedic frame of double bed, made of lamellae.

After the frame proceed to the installation of the legs. Cut several bars of identical length. They are mounted in the corners of the product. They can be inserted into the frame or secured from the outside, from the inside.

Lifting bed base

Use the spikes to fasten the legs directly into the base. This is the most reliable option. If the width of the bed exceeds 220 cm, you should install 5 feet in the middle of the product. For this purpose, a longitudinal board is mounted, to which it is attached.

The base of the bed mounted on five legs

Final stage

Now you can proceed to the assembly lamella base. These are transverse strips supporting the mattress and not allowing it to deform.

Slats in the base of the sofa

- Tamper on the base, side and end of the mounting rail.

- Mark at a height of at least 100 mm from the top.

- The rail is attached along the entire perimeter using a solid line and a dotted line. You can take a metal corner instead.

- It will take a bar with a cross section of 30x30. From it make a frame for the cross bar. Attach it to the internal parameters of the base.

- Then a rake having dimensions of 150x4x2 cm is packed onto the frame. Fasten it across the length. The distance is at least 5 cm.

To the metal frame, the slats should be fastened by metal fasteners.

If you perform all the actions, following strictly made drawings, you will not have problems with the installation. At the final stage, the base should be treated with emery paper and covered with varnish.

The holder can be completely invisible, but at the same time as strong as possible.

Carefully consider the choice of covering the finished bed. After all, it must fully fit into the interior of the room. Before covering the product with varnish, it is recommended to first tone it. For this suitable stain.

Reinforced metal mount for wooden slats

It should be applied evenly using a brush. It is necessary to varnish the surface only after the stain has dried. It is necessary to make 2 varnish coat.

Video: Making and installing lamellae on the bed with your own hands

50 photos of slats:

A bed with a soft headboard is an excellent solution in the design of the apartment

A bed with a soft headboard is an excellent solution in the design of the apartment

Bed transformer - a functional decoration of any room.

Bed transformer - a functional decoration of any room.

Soaring bed: What is it - exotic or affordable piece of furniture?

Soaring bed: What is it - exotic or affordable piece of furniture?

The advantages of creating a bed with drawers do it yourself

The advantages of creating a bed with drawers do it yourself

Bunk beds for girls: how to choose the right material

Bunk beds for girls: how to choose the right material

What is a comfortable bed with a lifting mechanism 180x200, pros and cons.

What is a comfortable bed with a lifting mechanism 180x200, pros and cons.