Bed-wardrobe do it yourself. Drawings, sizes, schemes

Bed-wardrobe do it yourself. Drawings, sizes, schemes

How to make a bed transformer with your own hands? It is quite easy!

Chest-bed transformer from chipboard, made by hand

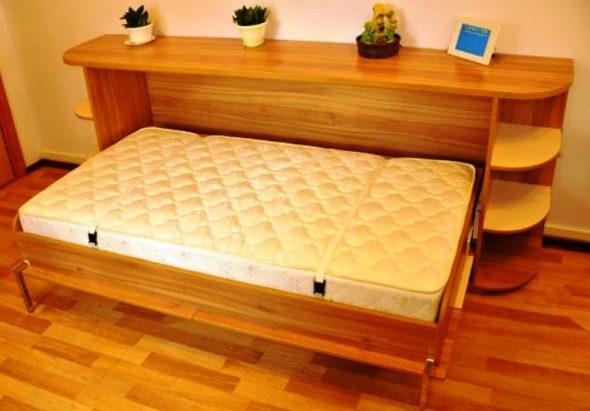

Most residents of apartment buildings face the problem of a small living space on which so many things need to be placed and organized. Bed transformer has become very popular thanks to these requirements. During the day, such a model can be a regular table or wall, and at night turns into a full-fledged sleeping place.

Bright dresser-bed desktop - a practical idea for your interior

Everyone wants a home to be cozy and comfortable, so this type of furniture must comply with the interior, the particular layout of the room. But the price of such products is quite large, not everyone will have to afford. There is always a way out - with minimal skills, you can make a bed transformer with your own hands.

Comfortable bright bed-wardrobe with shelves and lighting in the bedroom of two children

The advantages of making furniture with your own hands:

- space saving;

- affordable cost of the necessary materials (in any case, it will be much cheaper than purchasing the finished product);

- the ability to create a unique model that meets your requirements;

- all necessary drawings are available on the Internet;

- confidence in the quality and reliability of the finished product;

- sleeping on a bed with a high-quality mattress is useful, and on the couch you can harm the musculoskeletal system.

Furniture built into the niche of a small bedroom for rational use of space in the room

Content [Hide]

We determine the design and construction of the future bed

Bed-wardrobe disassembled and assembled, used in a small apartment

Before looking for drawings, to purchase the necessary materials, choose which particular product you want to receive and which model you will be able to manufacture. Beds transformers are divided into several varieties.

- Bed-wardrobe - with the help of a lifting device, the bed is pressed against the wall and looks like a simple wardrobe. This type is the most popular among the rest and is considered one of the predominantly practical in small-sized housing. A bed a transformer the hands of this type to create easier, than other models.

Double bed-wardrobe with a comfortable orthopedic mattress

Folding wardrobe bed with a table-secretary and with LED lighting

- Bed-workplace is popular for the arrangement of children, because it includes a desktop with all kinds of additional drawers, a wardrobe and a bed.

Table-bed for a teenager - functional furniture-transformer

Bed and desk - two in one for a room in the loft style

- Bed-sofa can be found as usual, and the option when the sofa is transformed into a bunk bed.

Double bed-sofa in the interior of a small cozy living room

Transforming sofa in a bunk three-sleeping bed

- One of the innovations - the bed rises to the ceiling and disguises there. It belongs to the transformers, since such a design instantly frees a large amount of space, becoming invisible.

Exclusive bed, rising up when necessary

White suspended bed near the ceiling in the interior of the room in the loft style

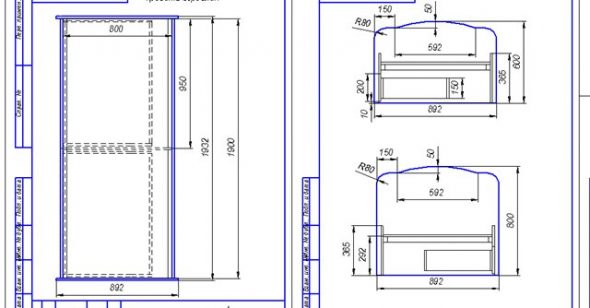

If you are a small specialist and for the first time start making your own transforming bed, stop at a simpler version. As mentioned above, such is the bed-wardrobe. To begin, make or find a drawing of the future product with the necessary parameters, marking the places of fixings and connections.

A bed that can be converted into a wall cabinet if necessary

The model of the bed-cabinet is divided into three main parts, which will first need to be created separately and then merged into one. The following are the elements and materials needed for manufacturing.

- The body can have any shape and appearance, the main thing is a large niche in which the bed will be laid. Niche should be made based on the parameters of the mattress. As material, you can use laminated sheets of chipboard, they are quite unpretentious in processing, have an affordable price. In order to avoid chipping during sawing, it is better to order a chipboard cut according to the required parameters from the manufacturer. This service is cheap, besides, all the edges of the parts you pasted edging tape.

The frame of the bed cabinet to be attached to the main wall

- The base of the bed - for making you need a wooden beam - from it you will make a frame and lamellae or a sheet of plywood, on which the mattress will go. Chipboard or MDF sheets are fixed from the bottom of the base - when folded, they will serve as the front of the cabinet, so this detail should be approached from a design point of view.

A bed hidden in the closet is a great option to save your space.

- The lifting mechanism unites a case and a bed. Since it accounts for most of the loads, it is advisable to purchase such a mechanism in finished form. This is one of the main parts of the transformer bed, you should not save on it, give preference to a quality system.

Mechanism of transformation of the vertical wardrobe beds in a disassembled form

Manufacturing process

Connection of two parts for a double bed - a frame and a sleeping part

Installation of a transformer-type bed consists of two points - the first step is to make a frame for a folding mechanism, and then a sleeping place. On the Internet you can find ready-made dimensions for standard single and double models, but if you need other parameters, you will have to calculate them yourself. In this great assistant will be the program “Furniture Designer”.

We attach the frame using the corners on the anchors, if you have walls made of concrete or brick, or screws in the case of a wooden house

Make a rigid fixation with anchor bolts of a sturdy metal rail on the wall. This will be needed in order to strengthen the frame with metal corners. For the base of the frame, take two reliable boards - they perform the carrier function, the average length for standard forms of transformer beds is about two meters. Along the edges, top and bottom, with glue and screws, secure them with a transverse board. Attach the trim to the finished frame with glue joints and self-tapping screws. Remember - it is necessary that the depth of the box matches the thickness of the bed. In the end, not to get a box that does not contain the finished product, it is better to make it a few inches more.

Installation of the cabinet frame beds using the mechanism of lifting the bed

Then you can start to mount the folding bed. Take as a basis the plywood that meets the required parameters. In order to avoid damage and sagging of the material, reinforce it from below by installing four boards along and across the future product. For greater comfort, you can equip the base of the bed with a variety of sides, but remember - nothing should hamper the lifting mechanisms.

Connected frame and base, with reinforcement of construction with a wooden block in the middle

The next stage - mounting the frame to the wall. For a long service life of the finished product, choose only high quality fasteners. Fix the hinged part to the frame with hinges, and fasten its free end using special fasteners - it is thanks to them that the bed will keep the transformer folded and will not suddenly decompose. If you will cover the wooden surface with varnish, it is better to do it as long as the folding part is not fixed with the frame.

The last step - the decor of the finished product

Built-in white bed in the closet with mirror facades in the living room interior

Bed transformer can be supplemented with small cabinets, shelves or mirrors, which will give the design more functionality. In variants of modern design, the product can be painted with acrylic paints - the most popular bright colors are in children's rooms. The bedroom can be decorated using a combination of several colors and drawing patterns. If you can not draw, on the Internet you can find a lot of stencils - print the desired one and use it to create a unique design.

Bunk children's bed-wardrobe with a pattern for two children

For greater compliance with the cabinet, the outer side of the product can be arranged with the help of invoice fittings, false crossbars and imitation handles. You can also create additional niches with the help of mirrors or install additional lighting elements - light bulbs, LEDs.

Wooden wall with two folding beds with a beautiful treatment of the front part

The end of the boards decorate the self-adhesive edge - it can be purchased at any hardware store. Attach the edge of the adhesive side to the end, walk on it with a hot iron. Next, hold a dry rag, carefully pressing. Excessive trim and sand with sandpaper.

As you can see, the result of the transformer's bed, made by hand, will turn out to be no worse than the factory one, but somewhere even better and will be unique in its own way. The main thing is desire, patience, strict adherence to instructions and the use of quality materials.

White bed-wardrobe with wood frame and with lighting in the inside

Video: Do-it-yourself wardrobe bed

Bed-wardrobe do it yourself. Drawings, sizes, schemes

Bed-wardrobe do it yourself. Drawings, sizes, schemes

We assemble a cot for the baby with our own hands.

We assemble a cot for the baby with our own hands.

Build a bed with a lifting mechanism at home

Build a bed with a lifting mechanism at home

Baby bed for a newborn.

Baby bed for a newborn.

Children's bed "Ikea" for children from 3 years

Children's bed "Ikea" for children from 3 years

What is a comfortable bed with a lifting mechanism 180x200, pros and cons.

What is a comfortable bed with a lifting mechanism 180x200, pros and cons.