Pine beds - the pros and cons

Pine beds - the pros and cons

How to make a bed with an orthopedic base

In the interior of the bedroom bed plays a major role. It should be comfortable, functional, stylish. Despite the large selection in furniture stores, you should still make a bed with your own hands. In the store most often the price of the bed exceeds its quality.

Comfortable bed with wooden slats at the base and built-in storage drawers

Content

The advantages of handwriting

Self-production has the following benefits:

Firstly, it is not as difficult as it seems.

Secondly, in case of independent production, selection of material under control, accuracy of preparation of parts, assembly. You can make such a bed as you want, and not the one that is offered. The choice of natural, harmless to health materials is very important, because on a bed in a dream a person spends the third part of all time.

Thirdly, a bed made by himself will cost at least 2 times less than that purchased.

A simple wooden bed with orthopedic homemade

The choice of design and design

Having decided to make the bed yourself, you should decide on the design and appearance. You should not plan a very complex structure, if the possession of carpentry tools is not at a high level. Double beds have a shape close to the square, single beds - rectangular.

You will have to choose one of the following options:

- ordinary bed, used only for rest;

Beautiful and comfortable double bed for relaxing

- bed with retractable storage trays, practical for a small room, saves usable space;

Comfortable bed with drawers for storage

- bed-wardrobe, when a bed is raised in the wardrobe while it is awake.

A bed-wardrobe will allow you to place a comfortable bed even in a small apartment.

Bed-wardrobe is great for small apartments, as well as if the bedroom and living room are combined. But it should be noted that the manufacture of such beds is more complicated than usual.

For an ordinary bed should consider the size and type of legs and headboard. They should match the style of the overall bedroom interior. Depending on the designer's design, the headboard may not attract attention to itself, and may become the main focus in the interior of the room. It is decorated with leather, upholstery, carving, mirror and wooden elements.

The height of the legs is calculated so that it is comfortable to get up. The height of the bed depends on the height of the legs. You should not make short legs if an elderly person is going to sleep, and also if there is a draft in the room. High beds harmoniously look in spacious rooms.

The headboard performs practical (protects the finish wall, holds the pillow) and decorative functions.

A wooden bed with a soft headboard is practical and comfortable.

Planning

The choice of mattress must be approached seriously

The manufacture of a bed begins with the choice of a mattress, the dimensions of the base and the whole bed depend on its dimensions. Then pick up materials, make up drawings and cost estimates.

The strongest and most durable base will be made of beech, ash or oak. The wood of these trees is the hardest, but expensive. Spruce, larch, pine will cost less.

Wooden double bed with beech slats

To purchase a mattress should be treated carefully. It is better to give preference to orthopedic. A bad mattress causes poor blood circulation and spinal diseases. The length of the mattress should be at least 15 cm greater than the height of the person sleeping on it.

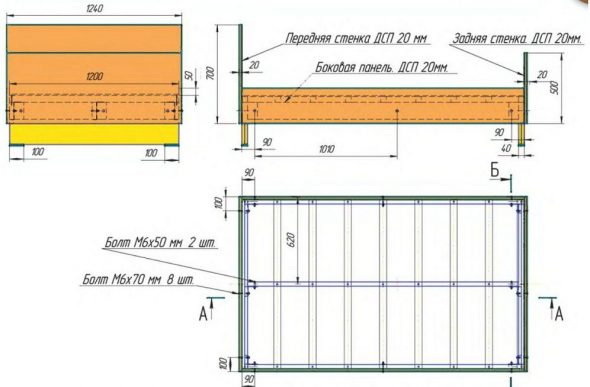

The dimensions of the base depend on the parameters of the mattress. If the length of the mattress is 2 m, width is 1.6 m, height is 0.2 m, then 1.5 cm is added to the base on each side.

The base of the bed is made of chipboard, wood or MDF. The most preferred wood.

The design and separate units homemade bed

Necessary materials

When choosing a material, one should take into account the harmlessness for a person, because it will take a lot of time to spend on it. The best material is natural wood. It is strong, durable, harmless, but also the most expensive.

- pine timber 50x50 2 pcs. 4.5 m each;

- laminated furniture chipboard (chipboard);

- MDF (fine fraction plate);

- plywood;

- fasteners (screws, confirmatics, dowels, plugs, eccentric clamp);

- glue;

- edging material.

It is necessary to prepare a headboard, tsarg, footboard. They are made after the choice of design and drawing up drawings.

Instruments

For work prepare the following tools:

- screwdriver;

- hammer;

- screwdriver;

- drill, drill;

- jigsaw, hacksaw;

- construction stapler;

- knife;

- pencil;

- ruler;

- laser level.

DIY bed making tools

Base for mattress

Support for the base is the construction of timber 50 X 50 mm. Get 2 pieces of 4.5 m.

Bar for the frame, suitable size

You should pay attention to the appearance of the timber and storage conditions. It should be stored under a canopy, resting on gaskets. A curved bar of high humidity will deform the bed. Blue or black spots indicate the infection of wood with a fungus. It can not be used for making beds.

It can be left unshaped, since it will not be visible in the finished bed.

Rectangular box for bed frame

The base is a rectangular box. To make the finished product look attractive, before assembling, every detail should be treated with an emery paper or a grinding machine.

- Elements of the box laid out in the form of a rectangle, check the perpendicularity and fasten them to each other with metal corners and screws.

Using screws fasten corners

- To the side parts from the inside for strengthening attach prepared timber.

The prepared timber for fastening from the inside

- When connecting parts for reliability, the joints are coated with wood glue. The length of the screws is chosen so that it is less than the total thickness of the connected elements. Otherwise, the screws will spoil the appearance.

- If the bed is very wide, then in the middle along the box it is worth making a partition.

The partition in the middle to strengthen the frame

- It is recommended to deepen the mattress 5 cm from the top of the side. At this level the rail is attached to the sides.

We select the slats for the base size

Indent between lamellae should be the same.

Lamellae will be supported on it. They are located across the frame, with an interval of no more than 15 cm. The lamels are made of slats or plywood 2 cm thick. The length of the lamella is measured across the width of the box.

You can make slats of boards for the entire width of the bed

The next stage is the headboard. It is made of chipboard, the fibers are arranged vertically, across the workpiece.The bottom edge is machined with a milling cutter to make the back look more attractive. The passage of the cutter must be taken into account when drawing up the drawings.

Having retreated from the bottom edge of the headboard, 3 holders are fixed at the edges and in the center with screws on glue. The holder is a 20 cm long bar.

Bed framework from a chipboard with lamels for a mattress and a beautiful back

On the sides of the headboard slab mounted racks, pre-made from the slab. Racks can be made chiseled, carved, use different methods of decor. It all depends on preferences, skills, financial capabilities.

The profile is attached to the headboard with dowels planted on glue.

Similarly, the headboard is made and fixed footboard. The only difference is that it is lower than the headboard. By tsargam it is attached using eccentric screed.

The sequence of actions when assembling the base of the bed

Installation of the bed is carried out on the spot where it will stand.

- The supports are attached to the main beam.

- Lay the support for the mattress, fix.

- Holders are attached to the backs, a timber is attached to them.

- Establish a basis under a mattress: plywood or a plate of a chipboard.

Build quality is estimated by the following features:

- there are no backlashes;

- the bed is steady;

- fastener is located exactly;

- in places of pasting there are no smudges.

Bed-podium

The design of the podium bed with drawers

The base of the bed-podium is made of timber and a board with a thickness of 22 mm.

The whole structure consists of three blocks, which are made separately. The side unit is attached to the headboard strictly perpendicularly using wing nuts. This will facilitate the assembly and disassembly of the structure. The blocks are assembled with pins with a diameter of 8 mm. The central unit divides the entire structure into two parts, each with a drawer. For the walls of the drawers, a board with a thickness of 16 mm is needed; for the bottoms, plywood is 10 mm thick. Skids are attached to the side walls of the crates, which slide along the corresponding parts fixed on the frame partitions. The boxes should not be made very deep, otherwise it will be impossible to push them completely.

Blocks are fastened with supporting bars, which are fastened with screws or self-tapping screws. At the end of the work install the front panel. Frame ground, painted in the appropriate interior color. All joints, seams, material defects should be carefully aligned before applying the coating.

If the bed-bed is located near the radiator, ventilation holes should be provided.

Ventilation holes for heat near the bed-podium installed near the battery

You should not have such a bed near the window, if the family has children. The risk of a child falling out of the window is very high. If there is no other place for a bed, then the window is opened only for ventilation.

Dressing

The finished bed covered with stain, varnish, paint. It all depends on the design intent.

We cover the finished bed with stain, varnish or paint

Pine boards covered with stain, because of the resin contained do not give a smooth tone, are covered with spots.

A self-made bed is an author's product due to unique ways of decorating.

The following tricks emphasize the important role of the bed in the bedroom interior.

- Place the bed on the podium. Suitable for a spacious room with high ceilings. Otherwise, the room will look overloaded.

- Build a canopy. It is mounted on the eaves, embedded in the ceiling. The bedroom will become more romantic.

- Selection of color solutions. The bedroom is recommended to be performed in soothing colors. It will look more interesting if the bed becomes a bright accent.

The headboard can be decorated as follows.

- Acrylic paints apply an interesting image.

- Use vinyl stickers.

Vinyl sticker gave a finished look to the bedroom

- Fabric upholstery, which is easy to do with the help of a padding polyester and a stapler, can also be trimmed with appliqué, embroidery.

Soft headboard - as an element of decor with your own hands

- Unusually decorate the headboard using rhinestones and glue.

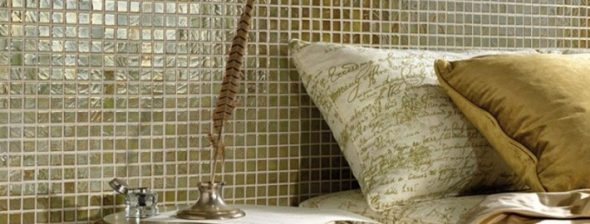

- The mosaic from ceramics, glass looks stylish.

Decorative mosaic at the head of the bed looks very unusual

- One or several small mirrors look beautiful.

The original headboard homemade bed from scrap materials

Decor items can not only be made by yourself, but also ordered from specialists or purchased in the salon. For example, carved legs, headboard, decorated with wood carving, gives the bed solidity.

A self-made bed costs less than a similar design in a furniture salon. At the same time materials will be of higher quality. In the manufacturing process, useful skills are improved, and creative possibilities are opened up.

Video: Budget Wooden Bed / Affordable wooden bed

Pine beds - the pros and cons

Pine beds - the pros and cons

Four poster bed - luxury interior

Four poster bed - luxury interior

Children's bed-transformer. Advantages and disadvantages

Children's bed-transformer. Advantages and disadvantages

Loft bed with wardrobe: where to put, why and for whom?

Loft bed with wardrobe: where to put, why and for whom?

How to install a bed in a niche in a one-room apartment

How to install a bed in a niche in a one-room apartment

How to make a children's bed with your own hands

How to make a children's bed with your own hands