Bed "Dolphin" - a bright element of the nursery.

Bed "Dolphin" - a bright element of the nursery.

How to make a bed of chipboard with your own hands: the advantages of creating

To date, the stores have a fairly complete range of beds, there are simple and strict, with exquisite carving, forging, with various additional functions. But it happens that the desired model is not found, or you want your own individual bed. Most often, of course, the question arises about the price-quality ratio, where the cost is too high for a good bed and the cheaper ones lose in quality. In this case, you can assemble a bed of chipboard with your own hands.

I want my own individual bed.

There are special drills, but you can get by with the usual ones.

Content

The advantages of creating your own hands

To finally be convinced of the correctness of the decision, we can identify the main advantages of self-production of furniture:

- Confidence in the quality of the manufactured furniture;

- the project is completely individual, tailored to personal characteristics and habits;

- the embodiment of any design, color;

- material is chosen independently, it will allow to choose inexpensive parts;

- the cost of a fully made bed will be much less than in the store;

- personal growth, increasing self-esteem, because not everyone knows how to make a bed with your own hands from chipboard.

You can assemble a bed of chipboard with your own hands.

Plus, it is worth noting enough. The main thing is to find time to design a drawing and build a bed.

The project is completely individual, tailored to personal characteristics and habits.

Fasten the headboard and side tsars with metal corners.

We determine the design and construction

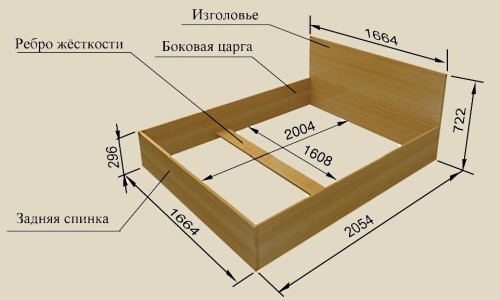

Before we get to work, you need to carefully consider drawing a bed of chipboard with your own hands. First of all it is necessary to determine the size. The length is not difficult to determine, you need to add 15-20 cm to the growth of the one who will use sleeping furniture. Width will be calculated based on the number of people and their physique. Couples should provide more sizes, children love to come to their parents in bed.

The material is chosen independently, it will allow you to choose cheap parts.

In the drawing, be sure to provide a place under the mattress. To make sleeping furniture comfortable to fill, you need to leave about one and a half centimeters on each side. The dimensions for a bed with a length of 200cm are as follows:

- 80-120 single;

- 120-140 one and half sleeping;

- 140-180 double;

- 180-220 family;

- from 220 three bedroom.

Before we get to work, you need to carefully consider drawing a bed of chipboard with your own hands.

If desired, the planks can be replaced with a solid shield under the mattress.

Sometimes the size of the bed determines the available mattress. Here we choose material in length and width 50mm more than a mattress.

First of all it is necessary to determine the size.

On sale often models with the lifting mechanism or boxes. If you want to make a bed with storage places, it is better to stop the choice on the boxes. It is easier, and the material will be cheaper.

In the drawing, be sure to provide a place under the mattress.

In each inner corner, under the bar, we will attach the legs.

Special attention should be paid to the headboard, it is the face of the entire product. Here are a few design ideas:

- Make the thread an electric jigsaw, give an unusual shape;

- apply artistic painting;

- headboard-lattice;

- wrapped in leather with a foam rubber insert, beautifully pulled;

- sew small pads, or several large;

- use decorative items.

Sometimes the size of the bed determines the available mattress.

If the plans to make a children's bed with your own hands, it is better to coordinate the drawings from the LSP with the child himself. This will help to take into account its features, besides children's imagination can qualitatively improve the project. In order for the assembly process to bring positive emotions, you can involve the whole family in it.

If you want to make a bed with storage places, it is better to stop the choice on the boxes.

For stability, it is better to add an additional leg in the middle.

Necessary materials

The second step involves determining the material used. The main part of the furniture will be made mainly of chipboard. It is an inexpensive and durable wooden-shaving plate. To find out how thick the material will be, we will make calculations based on the total weight acting on the bed. But it is better to immediately make the strongest foundation.

Special attention should be paid to the headboard, it is the face of the entire product.

To save time, the material on the furniture is better to buy laminated. Data on the amount of material is given in the table below.

| Name | amount |

| Solid sheet ldsp (headboard) | 1 |

| Side dresser | 2 |

| Bar equal to the length of the side bar | 2 |

| Beam or board to stiffen | 1-2 |

| Front wall of the box (footboard) | 1 |

| Equal slats equal to the width of the bed | 10-15 |

| Legs | 4 |

| Leg plugs | 4 |

In order for the assembly process to bring positive emotions, you can involve the whole family in it.

Put the mattress and make the bed.

To understand how to make a bed of ldsp with your own hands, you must have certain skills in sawing out of chipboard. And you can provide a drawing of beds made of laminated plastic, dimensions of the part and the material itself to specialists, they will make a cut quickly and efficiently. It is not free, but still cheaper than the store.

The second step involves determining the material used.

If necessary, the mattress is also possible to make yourself. To do this, it is enough to buy a pair of foam rubber or polyurethane blocks, and connect them. As a cover for a mattress, weaving is perfect for bed linen.

Required Tools

Most of the required tools are usually present in every man’s house. Of these, you will need:

- Screwdriver

- Tape measure and pencil

- Screwdriver (bit) for confirmats

- Iron for gluing veneer

To save time, the material on the furniture is better to buy laminated.

That's all, the bed of chipboard with their own hands is ready, without any difficulties.

You also can not do without additional fasteners and some accessories:

- Metal corners

- Confirmats and Plugs

- Screws

- Veneer for decorating the ends.

Most of the required tools are usually present in every man’s house.

Now, when all necessary is bought and sawn, it is possible to begin assembly.

To understand how to make a bed of ldsp own hands, you must have certain skills in sawing out of chipboard.

Manufacturing process: step by step instructions

Before we get to work, it is necessary to make holes for confirmats. For this there are special drills, but you can get by with the usual ones. For confirmability 7x70 take a drill at 7x5. Where the head and fastener head will go, we will use 7 drill, the rest of the length is 5 size of the drill.

If necessary, the mattress is also possible to make yourself.

Step by step assembly instructions

- To fasten the material of the head of the head and side pillars with metal corners;

- add footboard;

- strengthen the joints with confirmatories. It should be a rectangular box;

- install the support bar in the middle along the sides.For stability, it is better to add an additional leg in the middle;

- from the inside of the sidewalls attach the bars using confirmatics;

- in each inner corner, under the bar, we will attach the legs;

- lay the entire length of the rails on the bars and the support beam, keeping the same spacing. The quantity depends on the width of the rails and the gaps;

- fasten the slats to the bars and the support. If desired, the planks can be replaced with a solid shield under the mattress;

- attach decorative items, if any;

- put the mattress and make the bed.

When all the necessary purchased and sawn, you can start the assembly.

That's all, the bed of chipboard with their own hands is ready, without any difficulties.

Before we get to work, it is necessary to make holes for confirmats.

VIDEO:Bed with your own hands from chipboard. Detailing

Bed "Dolphin" - a bright element of the nursery.

Bed "Dolphin" - a bright element of the nursery.

Bed of pallets - an unusual solution in the design of home interior

Bed of pallets - an unusual solution in the design of home interior

Bed attic do-it-yourself - a choice of designs, sizes, diagrams and drawings

Bed attic do-it-yourself - a choice of designs, sizes, diagrams and drawings

Bunk beds for teens. Advantages and disadvantages

Bunk beds for teens. Advantages and disadvantages

How to put the bed in the bedroom, and how not to put?

How to put the bed in the bedroom, and how not to put?

Double bed - dimensions and technical features

Double bed - dimensions and technical features