A bed of pallets - a modern solution!

A bed of pallets - a modern solution!

How to make beds of metal with their own hands

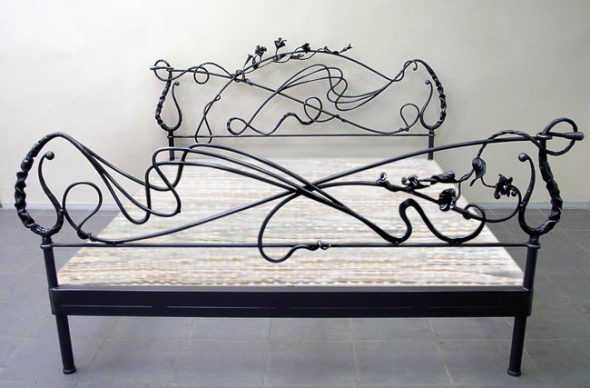

An iron bed is an object that can give the interior a special luxury and chic. Smooth metal bends add aesthetics to the bedroom.

An iron bed is an object that can give the interior a special luxury and chic.

One third of his life a person spends in a dream. Full night rest is a pledge of activity in the daytime, the quality of which only a comfortable bed can provide.

Smooth metal bends add aesthetics to the bedroom.

Furniture stores represent a wide range of choices of such a necessary piece of furniture. But not always and not in all respects it is possible to choose exactly what you need. In this case, the question arises of self-production of such an important piece of furniture.

Full night rest is a pledge of activity in the daytime, the quality of which only a comfortable bed can provide.

Content

Difficulties at work

Making an iron bed is a responsible, time-consuming and complex process. Is it easy to do it yourself? Each defines itself because of its capabilities and skills. Some knowledge is required. Replenishment of this knowledge. Creative attitude. It is necessary to start small - to get the lessons of an experienced blacksmith, or to ask for help from a knowledgeable person in this matter. Because it is likely to do something wrong. Trying to create yourself is a simpler option. In addition, you must have at least the simplest necessary equipment. The main difficulty lies in the preparation of components and their processing. All the necessary schemes can be taken from the Internet. The main thing is a little patience and self-reliance.

But not always and not in all respects it is possible to choose exactly what you need.

Sizing

Before you begin, you need to decide on future dimensions. This requires a clear understanding of where the bed will be placed and who will sleep on it. In the case of modernization of the apartment or room, you can move away from the usual stereotypes and choose a new place for it.

Making an iron bed is a responsible, time-consuming and complex process.

There are standard types of beds: single, double, one and a half. It should be remembered that a place to sleep should be 30 cm longer than the person who is going to sleep on it. Usually the length is 2 m, but can vary in the range from 191 cm to 213 cm.

Some knowledge is required.

With the width is also worth deciding. So, depending on the type, the width will have the following value:

- single - 91 cm;

- double - 137 cm;

- one and a half - 99 cm.

It is necessary to start small - to get the lessons of an experienced blacksmith, or to ask for help from a knowledgeable person in this matter.

Big options are for two people. However, they occupy a lot of space in the room. Therefore, before starting work, it is necessary to measure the space in the room under the bed.And also take into account parameters such as a place for a bedside table and just a place for free movement.

The main difficulty lies in the preparation of components and their processing.

Another important factor is the choice of mattress. When working, departing from the established standards, it should be noted that it will have to be made to order.

The main thing is a little patience and self-reliance.

Types of construction

The birthplace of the appearance of metal beds can rightly be considered Egypt. They were only affordable for prosperous people. They were a sign of wealth and luxury. In the Soviet Union, iron beds were made according to a pattern and did not differ in elegance. Currently, the situation has changed dramatically. Metal items appeared on the furniture market, differing in the way they were made. These include the following types.

- Forged structures - have a solid base of metal pipes. Pipes with a cross section of different diameter, which allows you to recreate a variety of scenes in the design. Weight is no more than 50 kg. Forging is of two kinds: cold and hot. In the first embodiment, all manipulations with metal are performed by a special apparatus. The process is more like stamping. In the second case, the master works with his own hands. Metal heats up to +600 C. With the help of forging, you can recreate an object in any interior style: classical, modern, rococo, baroque, ethno, high-tech.

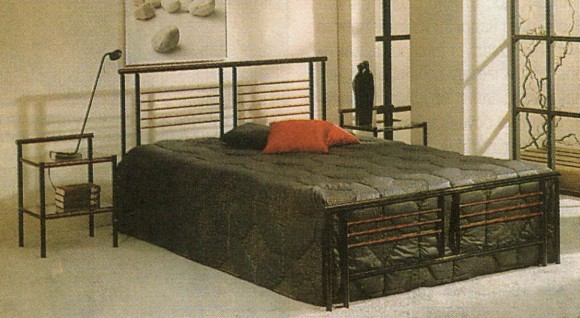

- Welded structures - differ from forged ones, by way of interconnecting the finished parts of a future product, by means of welding. Products made in such a way less original: classic or modern.

Before you begin, you need to decide on future dimensions.

Any bed consists of a frame, frame, back, legs and fasteners. The main elements that form the basis of any bed are the frame and frame. The frame serves as a support. Consists of backs and side panels. The frame is the part where the mattress is located. Particular attention in the manufacture, should be paid headboard. It carries a decorative role and completely sets the tone for the entire product. Forged elements are used as decor. They can be purchased already in finished form.

In the case of modernization of the apartment or room, you can move away from the usual stereotypes and choose a new place for it.

Preparation for the process

Before you start making an iron bed with your own hands, you should carefully familiarize yourself with the existing models and designs. Rate the complexity of production and its capabilities. Most of the options are quite simple in their performance and can be implemented even by a beginner.

There are standard types of beds: single, double, one and a half.

Further, it is recommended to make a plan. Describe all the steps, materials and tools. So money and time will be saved.

Decide on the size and model based on your wishes.

Metal items appeared on the furniture market, differing in the way they were made.

To make a bed with your own hands of metal, It is necessary to perform a series of preparatory actions aimed directly at production.

- Draw a drawing of the product.

- Purchase materials.

- Measure the size of the mattress, which is more appropriate to purchase before the production of the bed. So it will be possible to compare it with the product during the production process.

Forged structures - have a solid base of metal pipes.

Tools for work

To make a welded iron bed with your own hands, you will need, of course, a welding machine. As well as other tools:

- LBM (Bulgarian);

- drill with a set of drills for metal;

- roulette;

- gon;

- square file;

- metal brush;

- sandpaper;

- paint brushes;

- primer for metal surfaces;

- paintwork.

Welded structures - differ from forged ones, by way of interconnecting the finished parts of a future product, by means of welding.

For the wrought product, in addition to the main list, you will need to add the presence of blacksmith equipment. Depending on the type of forging, the set will be different. So, forging for cold type includes:

- snail - allows you to create spiral patterns;

- gnutik - designed to bend metal rods at different angles;

- flashlight - to create parts under the same name "flashlight";

- Twister - twists the twigs along the longitudinal axis;

- volumetric - allows you to make volumetric patterns;

- wave - equipment for creation of wavy patterns.

Any bed consists of a frame, frame, back, legs and fasteners.

For the hot type of forging, a horn, an anvil, shperki, handbrake, sledge hammer, tongs, hammers will be needed.

May not require all the equipment. The choice will depend on the final goal.

Step by step technology to create a metal bed

Creating an iron bed includes the preparatory work, installation and processing of the finished product.

The process begins with the backs. For this, blanks are prepared from the profile pipes according to the drawing. They are laid out on a flat surface, fixed and fixed by welding. It is necessary to monitor the degree of angles to obtain a flat design.

Next on the backs are installed steps and plugs on the open parts of the pipes.

At the next stage, the use of grinders and channels will be needed. Brackets are made for fixing the frame - 2 central and 4 side, with a slope of 5 degrees. The fasteners connect the back with the frame with a continuous welding seam. The optimal distance from the floor is 0.35 m.

To make the bed more sophisticated, all seams and protruding elements are cut by a grinder, processed with a special brush and grinder to the base of the metal.

- Preparation of material for frames.

Steel channels are cut into blanks. The size is determined from the calculation: the length of the frame plus 5-6 cm. Channels are connected by corners. For a better quality of docking in the horizontal shelf of the corner, protruding sections are cut off. The joints, as in the previous version, are welded with a solid seam.

When working, departing from the established standards, it should be noted that it will have to be made to order.

- Mounting frame.

The backs are set in a strictly vertical position, the frames are adjusted and the grooves are marked on the lower channel bar. Holes are drilled no more than 9 mm in diameter. The drilled holes are adjusted to the spike shape with a file.

Another important factor is the choice of mattress.

The main assembly is complete. The next step is to weld the grid under the mattress. It is welded to the finished frame.

Next on the backs are installed steps and plugs on the open parts of the pipes. They are usually covered with steel cups.

Therefore, before starting work, it is necessary to measure the space in the room under the bed.

To make the bed more sophisticated, all seams and protruding elements are cut by a grinder, processed with a special brush and grinder to the base of the metal.

Finishing is done on a well-prepared surface: primer is applied, then varnish and paint.

The advantages of beds made of metal

Despite the difficult process, metal beds have several advantages. Here is a list of some of them:

- environmental friendliness;

- wear resistance;

- hygiene;

- reliability: resistance to mechanical damage and weight loads;

- variety of design and style;

- light weight, which is convenient when rearranging furniture;

- not exposed to fire.

Big options are for two people.

The metal bed is attractive in its appearance and perfectly "fit" in any interior.And with certain skills and a set of tools, the process will not be difficult. In addition, this type of activity is an excellent option for the development of creative abilities and, as a result, obtaining an individual piece of furniture. Made an iron bed with his own hands will serve for a long time and reliably.

With the width is also worth deciding.

VIDEO: Metal bed do it yourself

50 photo ideas: how to make a metal bed with your own hands

A bed of pallets - a modern solution!

A bed of pallets - a modern solution!

Choosing a bed for a girl

Choosing a bed for a girl

Bed review by IKEA

Bed review by IKEA

Choosing a comfortable bed for a teenager

Choosing a comfortable bed for a teenager

Features retractable beds for two children and their use in the interior.

Features retractable beds for two children and their use in the interior.

How to put a bed in the bedroom.

How to put a bed in the bedroom.

Hello. I did not understand what kind of metal beds are made of?