Baby cot with a pendulum and a box.

Baby cot with a pendulum and a box.

How to make a headboard with your hands

The bed occupies a central place in the bedroom. On it you can sleep, relax, read, watch TV.

The most important element of the interior design of the bed is its headboard.

Let's talk about how the bed headboard can be and how it can be done with your own hands at home.

Content

Types of backs

The first option is classic, made of wood. The way the wood is processed depends on how the bed fits into the style of the bedroom. Strictly made headboards do not decorate, they are made rectangular or slightly rounded. Such furniture elements are lacquered or painted.

Aristocratic products decorate with a wave-like ornament, and elegant, made in the Baroque style, Empire or classicism, are true masterpieces.

The metal version is an ancient type of headboard. This option is used in many styles of bedroom interior.

This design headboard fit to the Romanesque and Scandinavian style.

A variant that uses mosaic or natural stone is another popular type of backrest.

It often involves sea pebbles, glass, ceramics and other materials.

Constructions in which textiles are applied are a frequent frequent occurrence.

Their wide distribution can be explained by the coziness and comfort brought by the fabric into the bedroom interior.

Certain types of textiles are suitable for different styles of bedroom decoration.

For baroque or rococo, velvet is used, and empire is suitable for atlas.

Looks stylishly bedroom furniture, decoration which is made partly of leather.

An element upholstered in leather gives it chic and sophistication.

The design in the form of shelves makes it possible to use the space of the bedroom, to free up extra space in it.

It is only necessary to make so that the objects standing on the shelves do not accidentally fall on sleeping people.

Mirror headboard is suitable for those who are not committed to Feng Shui.

This teaching does not use a mirror in the bedroom.

Materials and tools

Sheathing the furniture for the bedroom itself is quite difficult. But if you try hard, do not rush, you can get a good result. It is better when the construction is made by the master. But it is never too late to learn something new.

Before you get to work, you need to prepare everything you need.

You will need:

- A sheet of plywood with a thickness of 8 to 12 millimeters.

- Foam sheet from 50 mm and above.

- A piece of fabric of a decorative or technical look. It should cover the area of the head of the bed.

- Decor details for decoration.

Materials for the manufacture of the headboard.

Thought not to do without the following tools and materials:

- Electric drill;

- Jigsaw;

- Drill set;

- Furniture stapler;

- A set of staples for a furniture stapler;

- Construction knife and scissors;

- Twine;

- Screwdrivers and hammer;

- Glue;

- Two sets of buttons;

- Sewing kit.

Set of tools.

Cooking backrest frame

First of all, free the frame from the old plating. From the rear we nail or fasten a pair of boards or plywood with screws along the length.If you wish, lengthen the base with 5x5 cm bars. They may not be attached to the frame. They will hold the brackets that secure the cushioning.

Behind the frame will look ugly. You can cover it with plywood.

Marking holes

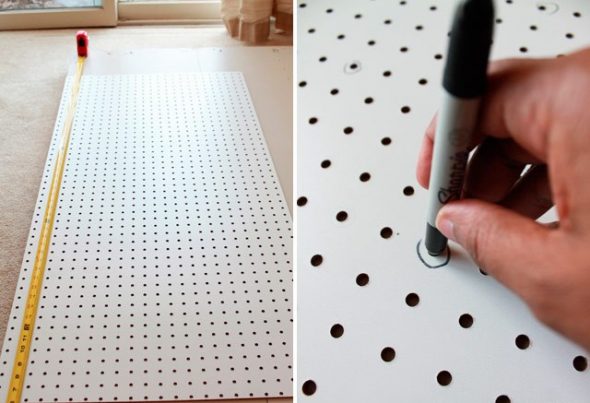

Mark up the holes that will be drilled to fix the material. A template for it will serve as a perforated plate Pegboard, which stores tools and other attributes.

You can trace already transferred holes on the perforated plate, so as not to forget what has already been done.

All work consists of the following steps.

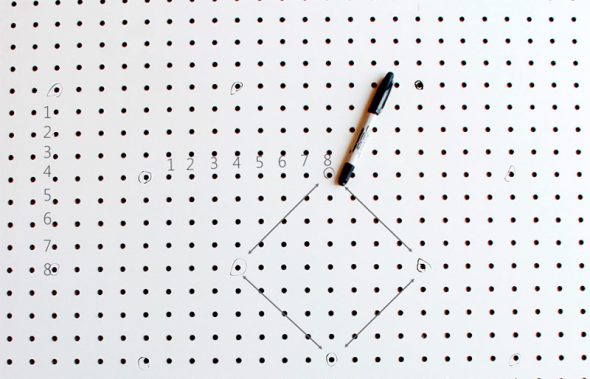

- We measure the skeleton and mark its center.

- "Center" the plate relative to the center.

- We start at 3 holes below the center that we marked.

- With the help of the marker we transfer the points of the future grooves to the core.

- We note on the tile already made holes, so as not to get confused. Mark the point, and after 7 holes set a new one.

- We continue to move in the same direction. The first point of the second row will be against 4 holes. The result will be a diamond shape.

It is not necessary to put points to the very edges of the headboard, leave several centimeters intact.

- Reaching the edge of the panel, move it, combining the marked points with the desired holes. So we continue until the half of the design at the top will not be marked out. We drill holes in the marked points for a needle to freely enter them. Shake off sawdust.

If on the back of the base something interferes with the free entry of the needle, the holes should be made through for a solid skin.

We fix foam rubber and fabric

We take foam rubber, dividing it into two pieces by size, and place it along the front of the back notch to the bottom. Align the sides and top of the foam. Excess cropped.

We fasten foam rubber on the sides and bottom with a stapler.

We drape textiles. We reserve margin on the edge from 25 to 30 cm. We put the structure vertically draped with the help of matter and abut it against the wall. It should be noted that when it is sheathed, we need free access to it.

Not bad to find a partner who would hold her.

We cover buttons

Now we are waiting for the most time-consuming work - weave buttons with a cloth. The set of buttons has instructions for use, carefully read it and get down to work. But first some work tips.

Remember to use good glue if you do not want the button covers to fall off over time.

- We cut out the fabric with a margin, a little more than the template that is in the kit. Excess can be cut off after we pound the cover buttons in the form.

- We get fabric and a cover in a form sideways, then accurately we insert.

- Before inserting the legs of the buttons, grease its edges with a drop of glue. Excess solution is removed with a napkin. It must dry at least the night, in order for the prepared buttons to be used.

We sheathe the design

For this procedure, you need to stock up on a long needle with a large eye, simple buttons and twine. You need to firmly tie knots on the rope. There should be several.

The knots on this smooth twine are easily decoupled, but then it freely passes through foam rubber and fabric.

We insert a long piece of rope in a needle and put on a button through all the holes, as if it were sewn. Tie it into several knots.

Make sure that you have tied a knot with quality (and more than once) so that it will not be untied over time.

We skip the needle through the upper central hole, which we drilled, and move from the back of the head to the front. Needle keep strictly straight. We pierce foam rubber with a needle, carefully pushing it from the outside. Take out the needle.

Be sure to keep the needle straight.

Fasten a dried button from the front of the headboard. For this:

- We skip the needle through the eyelet of the covered button;

- Turn the thread around the button and pass it through the eye again;

- We drown the button in foam rubber, at the same time pulling the thread (the loop keeps the button in this position);

- Cut the twine, leaving small tails;

- We tie the ends of the twine at the bottom of the buttons by analogy with the laces;

- We tie a knot on its reverse side, we do it repeatedly.

- Cut off the excess rope, hide the tips;

- “We pinch” the matter, forming it with folds.

Make sure all the folds are in the same direction.

After fixing the buttons, we form a fold that goes up. Then fasten the next one and form the fold again. Sew four buttons, stretch the material and fix the folds with staples.

Folds should look the same.

In a similar way we fasten the next buttons and form new folds of the 1st row. At the end of it, we continue to flash the remaining surface.

Following all the rules, every diamond on your back will be perfect.

Now small folds are formed and fastened after each button to get beautiful diamonds.

You need to microscin with your fingers after adding each new button to get perfect diamonds.

Fasten fabric

- After complete flashing of the base, you must fasten the fabric around the perimeter.

- We put the structure on the floor facing down. You can also drive a couple of brackets into the fabric attached to the top.

- For a neat decoration of the corners, we make bends, pulling the upper part to the bottom. Close it with a stretched sidewall and fasten the fold with staples.

The front side should look perfect, and the rear view is not that important.

- We continue further work in the same way. We try to achieve a perfect design of the external side of the structure.

- Before fixing the bottom edge of the fabric, we again put the backrest in a vertical position and cut off the extra pieces of fabric near the legs.

There is no point in fastening the fabric in front of the leg, because it is so well stretched behind.

Interior beds and backrest decor

The interior of the bed depends on the preferences of the owner. Usually the bed is bought finished or ordered by craftsmen. But now it became popular to decorate the soft headboard itself.

This method makes bedroom furniture unique.

The decor of the soft headboard can be very different. It all depends on your imagination and financial capabilities.

The original headboard will help highlight your style and taste.

VIDEO: Soft bed headboard with your own hands.

DIY headboard - 50 photo ideas:

Baby cot with a pendulum and a box.

Baby cot with a pendulum and a box.

Big problems of small apartments. Choosing furniture for a small room

Big problems of small apartments. Choosing furniture for a small room

Bed sizes matter

Bed sizes matter

Hanging bed do it yourself - a heavenly place to relax in your apartment!

Hanging bed do it yourself - a heavenly place to relax in your apartment!

Bed head to the window: a fashionable trick or stupidity?

Bed head to the window: a fashionable trick or stupidity?

How nice to make a bed

How nice to make a bed