The idea of placing and using the bed in the living room

The idea of placing and using the bed in the living room

Making a wooden bed with your own hands.

In the season of gardens and vacations I want to spend more time in the fresh air near my favorite fields, spruce and small river. But you have to spend time on returning to the apartment under the roof of the city high-rise building, because there is no comfortable garden house the bedsand your living room without a bedroom and a night bed is right next to a dining table. Do not despair!

Skilled hands and recommendations on how to make a bed with your own hands will save you.

Content

How to comfortably place a bed in the interior

It all depends on how and where you want to use it. A single bed is enough for your teenage child. the beds. If you are of large build, then a comfortable sleep will come only on the “lorry”.

Are you married? So you need a double one from solid wood.

If there is enough space, equip a pull-out bed under the podium, and on top place a cozy seating area with a coffee table, to which stairs lead. In a small room, where every square meter is expensive, build bed on the podium.

Embed drawers for storing bed linen, clothes and other things.

For bedding, place a tall, narrow drawer in the headboard with a top flap. It is convenient to keep pillows and blankets in it during the day, and at night - a cape.Assemble a beautiful decorative back and nail to the wall above the headboard. Place night lights on it.

This will give your bed aristocratic chic and comfort.

Choose a material and decide on the price.

The metal is too expensive, it requires a specially equipped workshop, a welding machine, it has a high specific mass and it retains heat poorly. Good furniture can be collected at home from quite affordable lumber, not overpaying for a well-known brand.

The construction of a wooden bed with their own hands will be cheaper than buying a finished store.

How to make a bed of wood with their own hands

Best for the beds medium wood (from 550 to 760 kg / m³) and high density - over 760 kg / m³. It wears less, but is harder to handle.

Optimum on durability and ease of processing is the pine.

IMPORTANT! Spruce is not suitable for bearing elements and bed legs. It quickly collapses from loads.

For the carrier frame pick up the boards or timber from solid wood - larch, birch. The legs can be made of bars, and the slats under the mattress are made of cheap pine boards 2 cm thick. Thin the boards from spruce 0.5 cm.Carefully check the material for knots, irregularities and roughness.

The fewer such defects, the easier it is to handle a grinding-machine.

Check the curvature of the blanks in a simple and effective way.

- Lift it at one of the ends to eye level.

- The ribs running from the near to the far end, in the future, should represent a straight line - their curvature will be immediately noticeable.

ATTENTION! Be sure to make a drawing. Consider the size of your mattress. They may not be as shown below. Internal frame space the beds should be a little more. Allowed allowance within 30 mm.

Immediately determine the presence and height of the legs.

Bed can be made of solid wood without them, gluing the fabric lining at the corners to protect the floor from scratches. For lightweight single beds and “half-corners”, the optimum height will be 35-40 cm - you can vacuum and wash the floor or build a drawer for storing things and clothes.

TIP! Try to strengthen the joints with a furniture corner where possible.

Making a wooden bed with your own hands may not be the easiest solution, but the most profitable.

Entry level bed

Under the mattress dimensions 80x190 or 90x200 cm, build a simple single bed made of wood. It will suit an adult or teenager. For the manufacture will need:

- Brus for four legs 50x50mm section;

- DOscar 25x245 mm for lateral sides and foot, 25x100 mm - for the manufacture of overlapping rails, 25x200 mm — for the headboard wall;

- Brus section 50x25mm for the manufacture of support beams under the slats;

Materials for the manufacture of beds.

In addition to good lumber, purchase:

- Furniture corners or bed ties.

- TO60 mm self-tapping screws;

- Shedges long 80 and a diameter of 8 mm;

- WITHtolyarny glue;

- Morilka or impregnation for wood;

- BUTkrilovy water varnish.

Required materials for work.

During the assembly of this and other options the beds use tools:

- DRel and screwdriver;

- Hsmall hand plane;

- RCircular saw or furniture saw;

- Shbodice machine or grinding machine;

- Ha few clamps;

- TOsources for applying glue, varnish and stain;

- Rmovable joinery square;

- WITHternary level;

- MAlka - a device for quickly marking the corners being cut;

- WITHTuslo - a tool for fast and accurate sawing blanks at an angle of 45 and 90 °;

- ANDmeasuring tape.

Tools that are useful in the work.

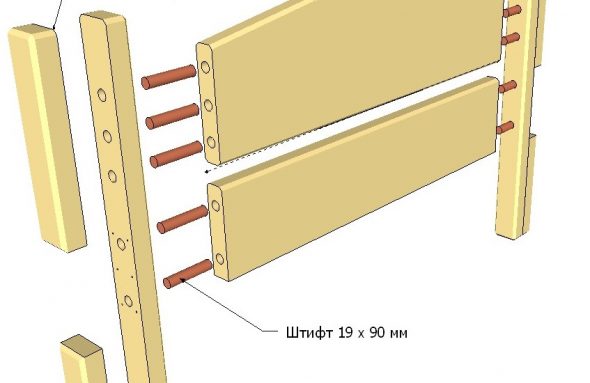

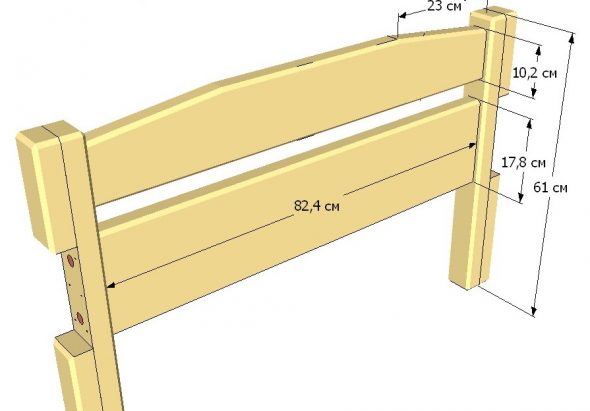

First assemble the headboard. Cut two legs up to 80 cm high from a 50x50 mm section bar. Drill 4-6 holes with a diameter of 8 mm and a depth of 30 mm in their upper part on the inside. From boards 25x200 mm cut two blanks 950 mm wide. From the ends, make holes up to a depth of 50 mm, coinciding with those that you made on the legs.

Lubricate the parts with wood glue at the joints and fasten them with dowels, carefully scoring with a mallet.

Footboard made from the boards 25x240x950 mm and two pieces of timber with a height of 400 mm.

Bind them the same way.

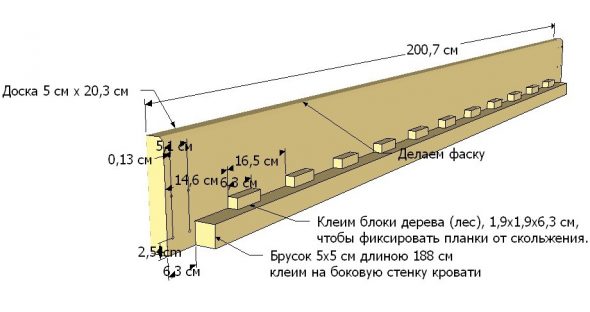

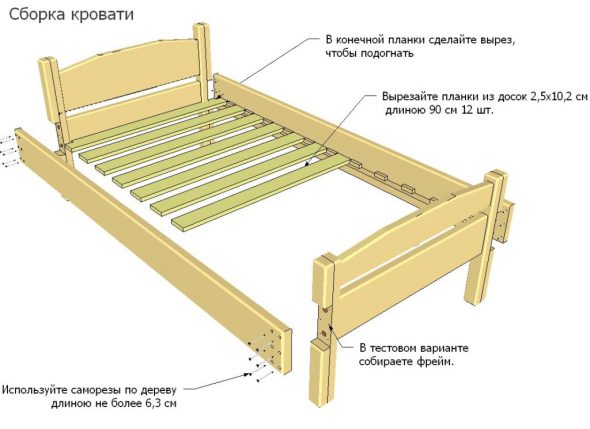

The backs are fastened to the side walls of 25x250x1900 mm with furniture corners or ties, aligned on the outer edge legs.

NOTE! Screeds make it easy to disassemble furniture when moving.

Along the lower edge of the right and left walls with the help of wood glue and clamps set the support beams 25x50 mm and long 190-200 cm. After drying, before removing the clamps, beams are additionally screwed with screws.

Assembling the side wall of the bed.

From boards 25x100 mm make 12-14 transverse rails long 95 cm. From the left and right ends of the drilled through-through holes with a diameter of 3 mm at a distance of 12 mm from the edge. Lay them across the supporting beams at a distance of 35-50 mm and tighten the screws.

The final assembly of the bed.

IMPORTANT! All parts must be sanded before assembly. With a sliding square, check the "straightness" of the angles between the side walls and the backs. the beds. Construction level control the horizontal arrangement of the frame elements.

Process a rough surface with a grinding machine. You can remove the chamfer from the outer edges of the backs and other parts to prevent chipping of the wood and improve the appearance. Treat for longer life. tree stain and dry. Cover with acrylic lacquer.

As you can see, making a wooden single bed is not at all difficult.

NOTE! To the ends legs When moving, they did not scratch the floor, you can glue felt pads to them.

Bed lorry

There are differences in the design of the backs, and its longitudinal axis is reinforced with a jumper with a leg that prevents the mattress from sagging.

It is made under the mattress with dimensions of 140x200 cm.

The headboard of the lorry consists of a wall and two legs. Wall make of 2-3 boards long 1400 mm and 25 mm thick, getting to the desired height (30-40 cm). The legs are made of timber 50x50x800 mm. The bond elements of the walls and legs it is made with 8x80 mm dowels, with wood glue and is reinforced with long screws from 65 mm.

The foot is assembled in the same way.

Side rails the beds-kolorkorki must be located on the same level with the lower boards of the backs and have the same height.For a change, change the design of the backs the beds. The middle wall board can be replaced with short vertical inserts from the same boards fastened with dowels.

At the outer edge of the top board, you can cut corners.

To do this, with the help of a special tool - beads - make the markup with a pencil. Malka consists of a handle pressed to the edge the boards, a narrow metal plate with a longitudinal cut, and a mounting bolt that allows you to fix the plate, setting the desired angle and length of the cut. In such a simple way, you quickly draw symmetrical cutting lines on the left and right ends. To prevent the hacksaw from moving away from the line, press the wooden guide bar along the marking with clamps.

To give an interesting look to the bed before varnishing, you can limit the application of stain to the surface of the legs and backs.

How to make a double bed of wood

Two adults are a serious weight., which requires a more thorough approach in the choice of material and method of assembly. Make a sleeping bed from wood.

It is based on a standard double mattress with dimensions of 200 by 160 cm.

You will need the following materials:

- BRussian 50х50 mm for legs and frames beds, 3x3 cm - for support beams under mattress slats;

- DOsca 20x100 mm for transverse flooring under the mattress;

- Mmetal furniture corner with a shelf width of 50 mm;

- WITHamoreza long 40 and 65 mm.

From the tools you need an electric jigsaw, equipped with a file with large and widely divorced teeth.

First we assemble the frame for the beds with internal dimensions of 210x170 cm and a height of at least 15-20 cm. To do this, we glue together three or four pieces of timber, we clamp them with clamps. After drying, we cut it in such a way as to obtain two blanks for the side edges. long 220 cm and two for the backs - 180 cm each.

In the same way, we assemble a longitudinal jumper with a height of 10 cm and a length of 210 cm.

When assembling, apply a lock connection. To do this, on short blanks with a jigsaw, cut out a recess, removing a segment from the middle long 5 cm. On long sidewall blanks the beds, leave the "spike", sawed off at the top and bottom of 5 cm.

Spread glue and spikes and connect them at a right angle, checking the sliding "square".

Attach a longitudinal jumper with additional support in the middle using a metal angle with a shelf width of 50 mm, aligning it with the bottom edge of the frame. Attach the legs of the timber up to 40 cm in the corners. Fasten using glue and screws.

For strength, fasten the connections with clamps.

For greater reliability, make legs the beds from a thicker bar. To give them an elegant look, chamfer from the inside at an angle of 45 ° using the miter box. Do not overdo it - the footprint should be large enough to support a lot of weight. When mounting the legs, use long bolts with heads in secret with washers and wood glue.

At the bottom of each corner, place triangular inserts that serve to prevent deformation of the structure.

Along the long side walls, glue beams from a 3x3x210 cm bar.

Their upper edge must be in the same plane with the upper edge of the lintel.

Do boards of 20x100 mm rails long 170 cm. They are laid and fastened across lintels and longitudinal support beams with an interval of 3 cm.

The first and last slats should be adjacent to the front and rear walls of the frame, the rest - evenly distributed between them.

IMPORTANT! So that the slats do not creak, make them 1 cm shorter than the inner width of the frame.

After completing the assembly, thoroughly clean the surface with a grinder or a drill with a special nozzle using medium and fine-grained emery paper.Cover with wood stain and, after drying, with water-based acrylic varnish in several layers.

For a double the beds You can make a wall headboard of 2-3 boards long 25x100x1800 mm and 10-12 boards 25x100x450 mm. The first row to be in contact with the back will go short the boards. On the seamy side must be equipped with hidden fasteners. At the appropriate places of the headboard, screw metal plates with screws, the free bottom edge of which will be inserted when hanging into the tire grooves.

The most reliable solution will be to fix the dowels on the wall of the tire for wall-mounted cabinets - by the number of short boards.

If you don't like a hard headboard, assemble it upholstered in the following layers:

- DSP or plywood 1 cm;

- Porolon from 3 cm;

- ATatin;

- ABOUTwadding fabric with an interesting pattern;

Saw a base of 45x180 cm from a piece of plywood or chipboard.

Remove the chamfer from the ribs and carefully handle the sandpaper so as not to tear the upholstery and batting.

From polystyrene foam or foam rubber cut the same in size and shape of the workpiece. Attach it to the chipboard and make several symmetrical holes for the decorative buttons. Measure and cut the wadding and upholstery fabric according to the shape of the blank with an allowance equal to the sum of the thicknesses of all the blanks multiplied by two.

Make sure the holes are symmetrical.

Using glue or a special spray glue the foam rubber to the base. Spread the batting gently on the floor. Place on it a blank of chipboard.

Bend the pooped edges, starting from the bottom, and nail the stapler to the chipboard.

Repeat this operation with upholstery. To prevent the fabric from wrinkling, iron it with an iron and tighten it properly using clamps screwed to the middle of the workpiece.

IMPORTANT! Do not skimp on staple staples. Nobody will see them anyway.

In conclusion, "sew" sofa buttons. From the seamy side of the headboard, pierce the upholstery with a large “shoe” needle and pull the thick coarse thread, pass it into the eyelet of the button and bring it back through the same hole.

Fix the ends of the thread with a stapler on the seamy side of the backrest.

Mount the upholstered headboard to the wall using tires for wall-mounted cabinets.

A wooden bed with your own hands, made according to a personal project, will be cheaper than a purchased one.

Remember, the lack of extra money and the lack of living space are not an obstacle to the realization of the desire to sleep comfortably.

VIDEO: Double bed made of wood with their own hands.

Wooden beds in the interior - 50 photo ideas:

The idea of placing and using the bed in the living room

The idea of placing and using the bed in the living room

Bed of solid oak: the pros and cons

Bed of solid oak: the pros and cons

Forged beds in a modern interior

Forged beds in a modern interior

Children's bed made of wood

Children's bed made of wood

Features, pros and cons of bunk beds for children

Features, pros and cons of bunk beds for children

Lifting bed with sofa: advantages and disadvantages

Lifting bed with sofa: advantages and disadvantages