How to make a bed-car for a child with your own hands?

How to make a bed-car for a child with your own hands?

What to choose: the orthopedic basis for a bed or flat continuous?

Many face this choice when it comes time to buy a bed.The question is, why buy an orthopedic base when you can get along with an orthopedic mattress?

If you decide to improve your body, engage in the selection of a bed with an orthopedic base.

Buying a good orthopedic mattress is a profitable investment in your comfort and well-being.

In this article we will answer this question and tell you what are the advantages and disadvantages of the reasons for what to look for when buying.

Content

Types of grounds

For beds produce two categories: flat solid and orthopedic lattice.

1) A flat solid is a surface made of planed boards, plywood or chipboard (made of pressed wood shavings). It is processed by protective and decorative means, attached to the frame. The solid base is heavier than the orthopedic, less mobile. And most importantly, it does not allow the mattress to reveal all its orthopedic characteristics and capabilities. Thus, the dream worsens.

This base interacts worse with the mattress due to poor ventilation, therefore, its service life is reduced.

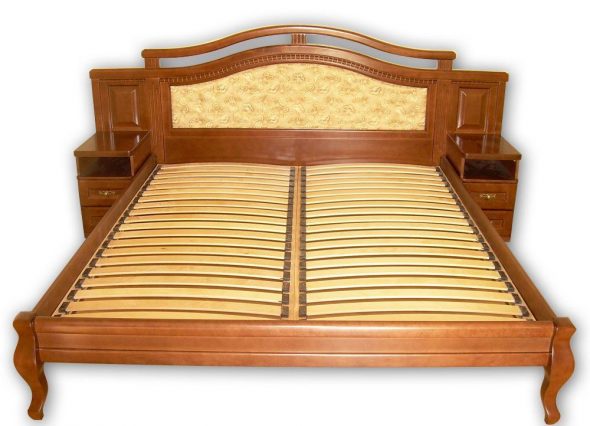

2) The orthopedic trellis base for the bed consists of a metal or wooden frame with a lifting mechanism and legs, wooden slats that are attached to it with latoderzhateli.

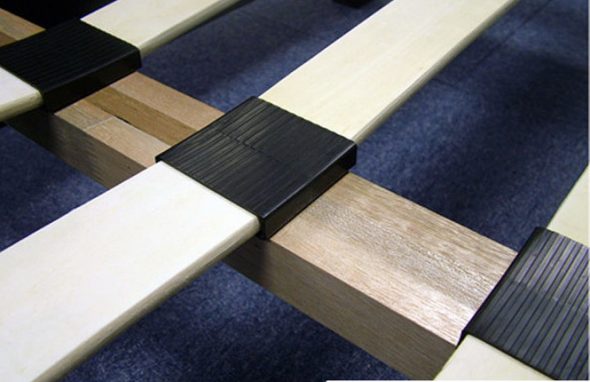

Lamels are wooden curved planks.

Lamella can be made of the following wood species:

- Birch tree;

- Beech;

- Nut.

Birch lamellae are the optimal material. They perform their functions with dignity and at the same time are cheaper than lamellae made of other wood species.

Walnut and beech slats are more expensive, but they are durable and withstand more weight.

Standard lamella sizes:

- Thickness is from 6 to 8 mm;

- Optimum width is 63 mm;

- Length according to the dimensions of the base;

- The distance between the lamellae is 70-80 mm; this distance allows to improve the orthopedic effect;

- The optimal number of lamellas from 11 to 13 pcs.

Lamellae provide a comfortable and anatomically correct positioning of the body.

Such sizes of lamels, allow to make a bed easier. They give it elasticity, harmonious interaction with an orthopedic mattress, which allows to achieve maximum comfort.

The lamellae grille withstands loads up to 150 kg.

All orthopedic bases pass all mandatory strength tests.

Features of the design of the bed with orthopedic base

In addition to these advantages, this design allows the bed to be more mobile, which will significantly save space in the car when moving, will facilitate unloading and loading.

This option is well suited for a rented apartment, motels, hotels.

Sleeping structures with such bases are disassembled and assembled with little effort, the following elements are separated from the frame:

- Sleeping place;

- Legs;

- Top base with lamellae;

- The bottom part, with drawers for linen.

Disassembled design, can be transported by car.

Such designs are equipped with a lifting mechanism, have the ability to compactly store things and bedding.The legs are detached, the slats are pulled out of latoderzhateli, remains a metal frame with a mattress.

All other parts of the design, compactly folded in the box.

Designs are issued 2 types:

1) Without stiffness adjustment;

The base of the bed without the ability to change the stiffness of the slats.

2) With stiffness adjustment (very important, at the same time convenient function for double structures).

This feature is convenient for a bed on which people with different weights sleep.

Using the adjustment, you can adjust the rigidity of the orthopedic base, individually for each person lying on it. There are 7 hardness zone points:

- Head,

- Shoulders

- Back,

- Pelvis

- Hips

- Knees,

- Feet.

Bed with adjustable stiffness of the slats throughout their length.

To bed base, it is important to choose the right mattress. Orthopedic mattresses are made with different fillings. These are mainly springs, horsehair, coconut coir, natural latex.

All these fillers do not cause an allergic reaction, well ventilated and moderately elastic, which creates the maximum effect for a comfortable sleep.

Dimensions

The length of the base should be 20 cm more than a person’s height, the width of a single base should be at least 80 cm. Such dimensions allow you to comfortably sit on the bed.

A bed with such dimensions does not take up extra space in the room.

The legs are made of high-strength metal, the most convenient length of the legs is 24-25 cm. The height of the base depends on them. The stability of the structure provides the number of legs (there are up to 7 pieces on the frame).

To enhance the design in the middle is the central frame.

The total height is 27-28 cm., It all depends on the manufacturer. The lamella grille serves to properly distribute the weight on the mattress and prolong the life of the mattress.

Choose an orthopedic base

When choosing, you need to pay attention to the following factors:

- The quality of the lamellae (they should not be large knots and cracks);

- The base should not creak, the creaking causes discomfort;

- The metal frame should not have rust, chips and scratches;

- Wooden bases should not have loosened holes for fastening, sharp untreated edges;

- Completeness of accessories;

- Slats should not be chipped;

An important criterion is the brand of the product, since the comfort of sleep and the period of operation of the orthopedic foundation depend on the quality of the product.

The fastening details of the slats affect the price and quality of the bed. Slats are attached to the base - lats.

Lato-holders are fasteners designed to hold the lamellae in a sleeping construction.

Lamels fasten with a convex side up. They are rubber and plastic. Rubber more elastic and expensive.

Plastic plastic holders are cheaper, but more rigid and durable than rubber ones.

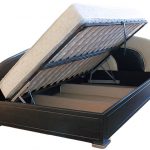

The orthopedic bases, make with the lifting mechanism. Mechanisms are divided into several types.

- The manual mechanism is reliable and has a longer service life than all the others, but is inconvenient, because when opening it is necessary to hold the base and the mattress at the same time.

- Spring, it is difficult to rise, but copes well with its task, over time it has to be changed due to the fact that the springs are stretched.

- Gas shock absorbers open smoothly and silently, mainly used to lift heavy bed structures.

- Lifting mechanism with an electric drive - it is convenient to use, it is driven by a remote control.

Beds with a lifting mechanism can be equipped with boxes for linen, thereby saving space in the bedroom.

The legs are made of high-strength metal, have a comfortable height, are easily detached and join the bed frame, ensure the stability of the whole structure and additional mobility of the bed.

The orthopedic basis with adjustment

Adjustment is of two kinds.

1. Regulation of lamella stiffness.

This adjustment allows you to customize the bed to your weight.

2. Adjust the top and bottom of the base.

This type of adjustment will allow you to comfortably enjoy breakfast, ensure the blood flow to tired legs, putting them on a slope.

Reliability and durability are not lost from such functions, since the manufacturers take into account all the necessary moments during testing.

Summing up

The advantages of classic beds that have a solid foundation are thatThey are designed for more weight than with an orthopedic grille and are more stable due to their weight.

The disadvantages of the bases of such beds are that they are more bulky, less mobile, they have a shorter mattress life, they are more difficult to repair than beds with an orthopedic base.

Orthopedic beds also have a number of advantages and disadvantages.

The advantages of such beds are much more than disadvantages. They pcalculated on weight up to 150 kg, lLightweight, mabundant, bQuickly understand and assemble. There is inThe ability to adjust the stiffness of the bed individually. There is a big pa variety of designs, wwide price range.The frame can be used independently of the bed. Beds, equipped with a lifting mechanism, easy to use.

At production of such beds modern technologies are applied that expands their opportunities and gives additional comfort.

Disadvantages only that such bedsdesigned for less weight.

Useful recommendations

If a sleeping person weighs more than 90 kg, then you need to use narrow slats, wide ones are suitable for people with lower weight. Some manufacturers of bases and produce mattresses. It is recommended to choose mattresses and bases of one manufacturer.

Additionally, you can get a discount on products.

Pay attention to the completeness, from some manufacturers legs are ordered separately.To feel the full effect of the orthopedic mattress, the mattress is bought first, then under it. If you do not have enough money to buy a suitable option, in many outlets you can get a loan, thus you will make a long-term investment in your health.

An additional advantage of the orthopedic grille is a quick repair.

Instead of a broken lamella, you can always order a product of the right size, buy it in a store.Many sellers offer their customers free shipping grounds. — this is another nice bonus.Sellers and manufacturers who value their reputation always go to meet customers and exchange goods in the event of a manufacturing defect.

Remember: a quality, properly performed orthopedic foundation is the key to a healthy sleep.

VIDEO: Instructions for assembling a bed with an orthopedic base.

Beds with orthopedic base - 50 photo ideas:

How to make a bed-car for a child with your own hands?

How to make a bed-car for a child with your own hands?

Original double beautiful beds

Original double beautiful beds

Can I put the bed feet to the door?

Can I put the bed feet to the door?

What should be the height of the bed?

What should be the height of the bed?

Choosing beds for children: what is the first thing to look at?

Choosing beds for children: what is the first thing to look at?

Provence bed: the charm of the south of France

Provence bed: the charm of the south of France

Another paid article about the use of orthopedic bases and about the uselessness of a hard base. Just forgot to write that the supporting properties of a high-quality spring mattress and even many of its orthopedic qualities will completely disappear if it is placed on an orthopedic foundation. Ask yourself: “What will happen if the spring of one stiffness (mattress spring) is placed on the spring of another stiffness (on the lamella)?” - the softer spring will work. And how many people, abandoning orthopedic grounds, placed the mattress on a hard surface and discovered its true properties for themselves;

10-15 thousand is what? Bed of substandard materials? In the first half of the year 3 lamella cracked, weigh 70 kg I sleep alone. Now you need to buy a new base, the cost of 2-6 thousand. It is difficult to find in the sale of beds with a solid base, everywhere lattice. Received a serious back injury, the master asks for 4000 plus the cost of plywood for changing the grid base to solid (plywood). So, if you have back problems (50% of the population have them), you can only use a solid base, no bars. Do not believe in this explicit advertising. A grated base will ruin your back and requires constant repair.

I agree completely with Mitya !!!!

I agree completely with Andrey

I agree completely with Vitka!

I agree completely with Sanka

Agree completely with Paschke

Mityay straight from the language took off! All these lamellas fly to hell in a couple of years, an article to increase the sales of these disposable lamella beds! Only a solid foundation!

I agree completely with Galina

Lamella bases are different. There is debris from TU, discounted, rejected lamels, which remain after being sent for export (yes, in Russia there are three most modern plants that make lamellae and cover the need of 60% of the European lamella market, including the German market). Look for manufacturers that use lamellas according to GOST, export version - you will be happy.

With springs, the analogy is correct only if the spring is one with a rigidity of 100 and the other is 5, then a softer one will work - naturally. B is also true - there are some manufacturers of mattresses that recommend using only a flat bottom or straight slats from an array. BUT they are very expensive, these are premium mattresses, which in Russia buys from the strength of 5% of the population.

Ordinary population - lamellas will help significantly. An inexpensive mattress with weak orthopedic characteristics with the correct lamellae will work as a mattress of the middle segment. In turn, the mattress of the middle segment - will be felt as more expensive and so on. Slats work together with the mattress, allowing you to extend its life

In the design, where one spring or two such works - which one will last longer? Or, returning to the analogy to automobiles, in the design of a vehicle's suspension there is both a spring and a shock absorber strut — they have different goals and they complement each other. So the base with the slats and the mattress - work in pairs.

P.S. Mitya, the correct slats are harder than the springs of the mattress and work after the mattress has taken the load

P.S.S. A comment from the heart, not from money, I can not look calmly while on the Internet someone is wrong

Lamellae can not extend the life of the mattress! Why attract by the ears of all these nonsense marketing? The larger the support area of the mattress - the longer it will serve. This is an axiom. There is a decent distance between the lamellas, some independent springs generally hang in the air - there is no support! As a result, the mattress becomes wavy, no wonder manufacturers recommend every three months to turn it over. With the solid foundation of these problems, there is no default. At the same time, any orthopedic mattress on the monolith will work better, because all springs have a stable base. Lamels - just marketing.

Do not advise anyone lamellar base.

I myself worked in the field of selling beds and mattresses, and I know that it was created solely for the appreciation and appearance of a better bed. In fact, the mattress works much better without them. We were constantly asked to replace certain parts of these bases. After a while, they may start to creak. I advise you not to overpay for the foundation, but rather to throw this money on the mattress.

I worked like that in Moscow for the production of beds and mattresses at one time. The material that sheathed the mattress was really imported, but the mattress was our domestic. Three expensive on Lenin. So this was the story. So more closely when buying such things