A computer chair in the house is not a luxury, but a necessity.

A computer chair in the house is not a luxury, but a necessity.

A drill for furniture hinges: what is it and how does it work?

When installing furniture connecting elements, it is convenient to use a drill, where a special drill is used, with which you can evenly select waste material and make a hole to the required depth.

Furniture hinges, attached after processing the base with such a tool, “sit down” smoothly and securely.

To equip the drill with a drill that is suitable for the hinges selected is the main task when working with cabinet furniture doors.

Furniture hinges, attached after processing the base with such a tool, “sit down” smoothly and securely. It is important to choose the correct diameter of the drill, depending on the parameters of the hinge bowls.

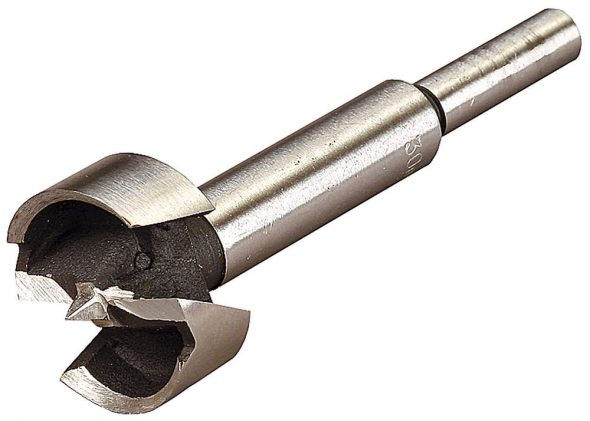

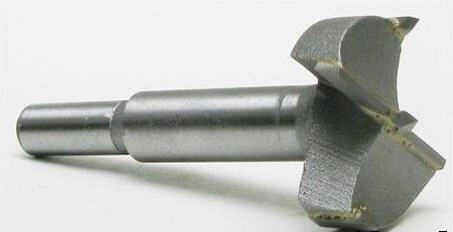

The drill for furniture hinges is a special milling nozzle that allows you to work with wooden and plastic bases of sufficient width.

Milling elements should be selected in specialized stores.

Content

What is it and how does it work?

The drill for furniture hinges is a special milling nozzle that allows you to work with wooden and plastic bases of sufficient width. With it, you can make the right hole in a solid panel, canvas MDF, chipboard or chipboard.

With it, you can make the right hole in a solid panel, canvas MDF, chipboard or chipboard.

You can find both standard and non-standard drill with a quality certificate and warranty from reputable manufacturers.

The nozzle is a base with a jumper and three teeth. The middle spike is placed in the center of the future circle, which is delineated with the help of the prepared caliber, and the others are made with a round hole of the required diameter. Typically, the depth of the final notch is about 9 mm.

The nozzle is a base with a jumper and three teeth.

Too cheap items - an indicator of poor-quality product, so you should consider options with the price of the average market.

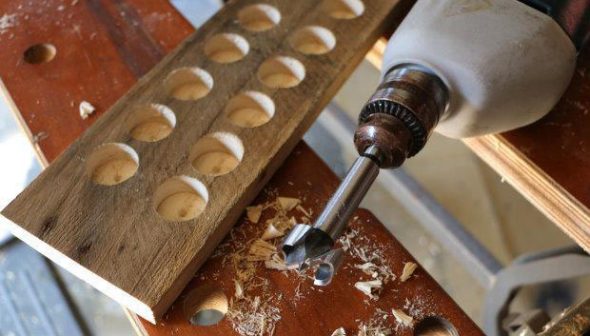

Furniture hinges for which the drill is used, mainly four-hinged. The hole for each is done almost instantly. The drill is held at work a little obliquely, not directly, so that the waste material is chosen to the desired depth and evenly.

Typically, the depth of the final notch is about 9 mm.

Such mill is reliable and will serve long.

Kinds

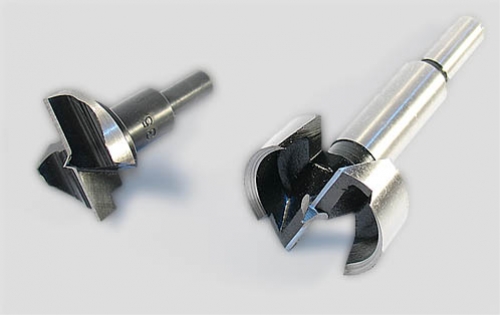

When installing hinges on cabinet furniture, two types of drills are used, differing in size:

- 35 mm;

- 26 mm.

The hole for each is done almost instantly.

It is important to choose the correct diameter of the drill, depending on the parameters of the hinge bowls.

The diameter is chosen according to standard hinges or with a reduced bowl. Each type of attachment is chosen its own drill.

With it, you can make the right hole in a solid panel, canvas MDF, chipboard or chipboard.

The nozzle is a base with a jumper and three teeth.

The drill for installation of furniture hinges is suitable universal, with interchangeable mode nozzles.

The drill is held at work a little obliquely, not directly, so that the waste material is chosen to the desired depth and evenly.

The middle spike is set to the center of the future circle, which is delineated using a stocked caliber.

On milling machines used automatic calibration and nozzles, in the same home conditions without special hand tools can not do.

The diameter is chosen according to standard hinges or with a reduced bowl.

Each type of attachment is chosen its own drill.

Advantages and disadvantages

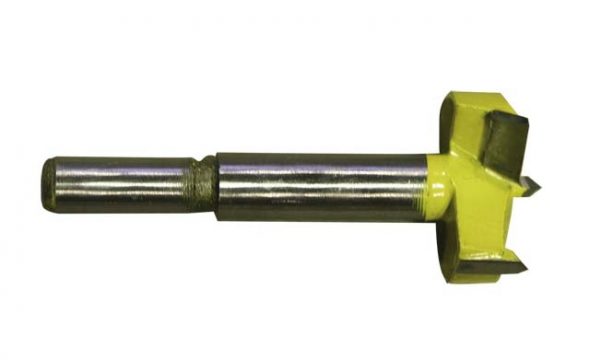

Furniture hinges require installation accuracy, so the ability to make exactly the deepening that is needed is the main plus Forstner drills. This provides a special stop, preventing the penetration into the hole beyond a fixed length. The drill is limited to the teeth, which do not allow to deviate from a given place. The hole is perfectly clean, so that the cup of the loop fits very tightly.

The drill for installation of furniture hinges is suitable universal, with interchangeable mode nozzles.

At home, without a special hand tools can not do.

The disadvantage of the Forstner drill when working with solid wood can only be its low quality, typical of non-factory production. Therefore, it is necessary to choose a product from an official supplier and get a guarantee.

Furniture hinges require precision when installing, so the ability to make such a recess is possible.

Depending on the type of panel, the cutter can be very hot, cauterize the edges and material chosen from the dimple. Therefore, when working with such a foundation, it is recommended to take breaks to cool the drill, making 3-4 approaches. This usually happens with MDF panels. In working with chipboard and chipboard elements of hard alloys allow you to make holes for loops quickly and without great effort.

The drill is limited to the teeth, which do not allow to deviate from a given place.

How to choose?

To equip the drill with a drill that is suitable for the hinges selected is the main task when working with cabinet furniture doors. To make the hole fit exactly along the radius and depth, you need to take the cutter of the required diameter.

| Four-hinge hinges with a 35 mm bowl | With such parameters, the drill should be appropriate. |

| Non standard mounts | Requires a suitable nozzle diameter.

|

| Forstner drills | Suitable for wooden and plastic panels with a thickness of 16 mm. |

The hole is perfectly clean, so that the cup of the loop fits very tightly.

The product is necessary from the official supplier and to secure a guarantee.

Milling elements should be selected in specialized stores. There you can find both standard and non-standard drill with a quality certificate and warranty from reputable manufacturers. Too cheap items - an indicator of poor-quality product, so you should consider options with the price of the average market. Such mill is reliable and will serve long.

Depending on the type of panel, the cutter can be very hot, cauterize the edges and material chosen from the dimple.

VIDEO: forstner drill

A computer chair in the house is not a luxury, but a necessity.

A computer chair in the house is not a luxury, but a necessity.

To pick up a baby bedspread for a boy's bed

To pick up a baby bedspread for a boy's bed

How to drag a computer chair with their own hands.

How to drag a computer chair with their own hands.

We use sofa cushions as interior accents

We use sofa cushions as interior accents

Guides for drawers. Types and features.

Guides for drawers. Types and features.