Furniture edge - what is it and why is it needed?

Self-adhesive furniture edge - a narrow strip of melamine, polyvinyl chloride, ABS plastic or other material

Furniture edge - a useful element for both craftsmen, making furniture with their own hands, and for any owner. With it, you will be able to revive the old utensils and protect it from rapid destruction. Perhaps not everyone understands what useful invention we are talking about. Then we will analyze what the furniture edge is, what kinds of it are, and why it is used at all.

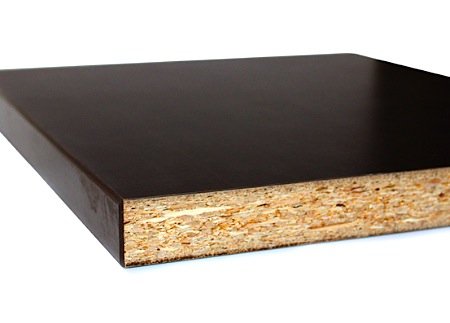

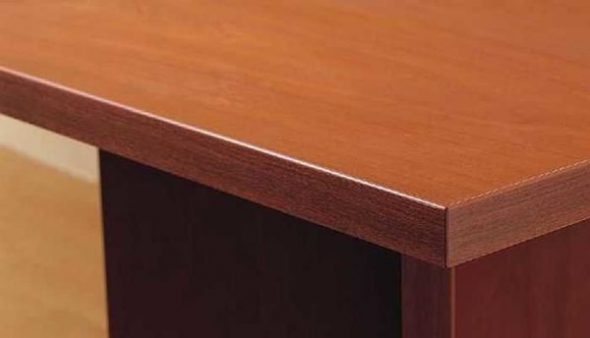

Thanks to the edge of the chipboard, it gains protection from chipping, swelling and other deformations,

If you make furniture with your own hands, you know the need to process the ends. After cutting the slab, this procedure is necessary. It will be especially useful for chipboard, as water and dirt can get into unprotected cuts.

The use of furniture edge is a mandatory step in the manufacture of furniture.

In this case, the product will deteriorate faster. It is for processing saw cuts used furniture edge.

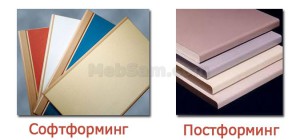

Postforming and Softforming are very high-quality ways of edging chipboard, which are made on special machines

This product is a finishing material, a narrow strip of melamine or other materials designed to be mounted on the ends of the furniture. Its main functions are protective and decorative. It hides the places where the chipboard layer is visible from the inside. It is known that this wood-shaving material, and it has a somewhat unaesthetic appearance. Furniture edge in this case is just salvation.

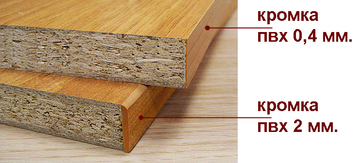

PVC edge for furniture is considered to be a better, durable protection of the butt of the part.

The second function is protective. In addition to protecting the furniture itself, it helps to avoid injuries and drags on clothes. Sawed edges of the chipboard are sharp and often spoil the clothes, you can also get hurt about them. They are especially unsafe for the kitchen and children's room. Therefore, it is necessary to process edges. A furniture edge is best suited for this purpose.

Difference of PVC of a covering of 0,4 and 2 mm

Content

Varieties

Popular types of furniture edge

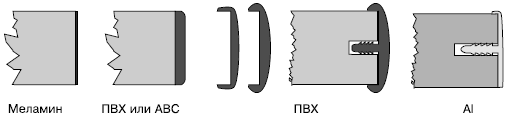

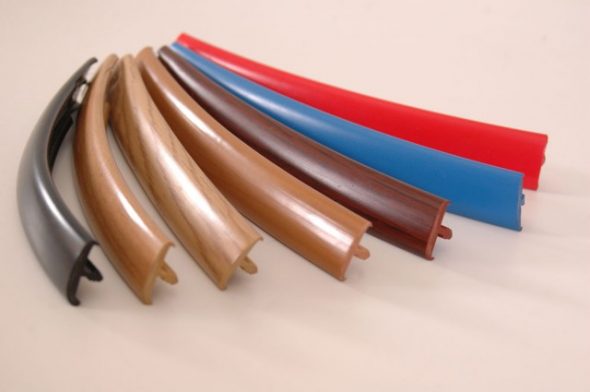

There are several types of edges. Basically they differ depending on the composition, thickness and appearance.

Melamine edge with glue - the most budget, but not the highest quality look

The edge of the ABS - durable and reliable thermal plastic, convenient to use

PVC edge is very popular for facing the chipboard ends

So, we present the most popular species.

| View | Description |

| Melamine | Most common for home use. This is a tape of melamine on the back side of which a layer of glue is applied, which is activated by heating. It is inexpensive, but the quality is no different; afraid of moisture, and its life is short, even with careful treatment. |

| PVC | The best option in terms of price and quality. Used in most modern products. Represents PVC tape in 2, or 0.4mm. The thicker one is used for processing the outer sides, and the thin one - for the cuts on the back side of the product. Processing of this type is carried out only in production, as this requires a special machine. |

| ABS plastic | Also a good option, similar to the previous one, only has a more environmentally friendly composition.On sale is extremely rare. Used in the manufacture of furniture in the factory. |

| Mortise T-profile | In modern production is rarely used, but is on sale. This is a more reliable option than the previous ones. The T-profile has a stronger basis and greater thickness. It is made mainly of laminated chipboard. Has spike connection. On the profile there are spikes that are inserted into the grooves on the furniture (pre-drilled). |

| Surface profile C 18 | Used for a long time. Still remains popular in the manufacture of furniture both at work and at home. It represents a non-flexible tape made of chipboard, which is put on the trimmed part of the plate and is attached with liquid nails. It is quite easy to use, so it is common in self-made furniture. The downside is its location. The edge protrudes several millimeters beyond the furniture, thereby increasing its size, and thus dirt is clogged under the ledge. |

Mortise T-profile - inserted into the milled groove in the end of the chipboard

The P18 profile P-profile is a good option, it can be used for chipboard at home

Veneer is not the most popular material for shredding, special skills are required to work with it

At home, melamine edge is most commonly used. It is easy to use and is available in a large assortment in the construction market.

Acrylic edge with three-dimensional image (PMMA-3D)

The most popular in Russia PVC edge Rehau has a wide selection of colors

Apply an edge with your own hands

Get this edge at home is quite realistic

It is possible to process cuts with the help of the PVC edge exclusively on the production. This procedure is not difficult to order with the purchase of plates, or as a separate service. But if you only need to repair old furniture, or simply do not want to apply to the production, you can process the cuts in this way at home.

We glue the edge with your own hands at home

To do this, you must purchase a melamine edge. Also cook:

- building hair dryer or old iron

- sandpaper;

- clerical or construction knife;

- a rag;

- stand with the function of fixing parts (suitable vise or help someone).

Edging tools and materials

We will stock up with more dexterity, and we can proceed to work.

- Fix the part with the machined side up.

We put edgeband on the part

- Measure the length of the edge being cut and cut the required amount of the edge with a margin of a few centimeters, since it will sit down a little from the heat.

Select the edge and cut to size

- Now attach the cladding material to the product and carefully heat it with an iron or hairdryer.

The detail is fixed and cut off the edge with a margin of several centimeters, heated by an iron

- Until it has cooled and the glue has not hardened, it is necessary to walk along the surface with a cloth, smoothing and pressing the material.

Until it is cooled down, it is necessary to press the edgeband well using a rag.

Tip!

Treat areas of 30-40 centimeters gradually. So there will be less damage and errors.

- Having worked in this way the entire surface, we proceed to the final stage. Now you need to trim the excess. To do this, take a construction or office knife, keeping it at an angle to the plate, cut off the excess material.

Cut off the excess, first cut off the end parts, and then those that go along

- We process cuts with sandpaper, eliminating their sharpness. Do the processing carefully so as not to damage the slab.

After the remnants are cut from the part, all edges along the edges of the part are rubbed over with a scraper.

- Wipe the product with a damp cloth to remove dust and dirt - work is finished.

Glued edge on the ends of the part

Thus it is possible to process small products, more volume is better to entrust a professional.

Advantages and disadvantages of home treatment

In self-processing there will always be both advantages and disadvantages. As a rule, there are more positive moments. In this case, the undoubted advantage is the speed and price of work. You do not have to wait until the product comes out of production, you will not need to place an order and pick it up. Naturally, doing the work yourself, you pay only for the edge.

The downside is the limited choice, as you can apply only the melamine edge, invoice or mortise profile (which are quite rare).

Handling a small surface with a melamine edge is quite simple, and it is better to do it at home. But a great product that requires the application of PVC edging is best left to professionals.

Video: Types of end edges of chipboard

How to make a stool from chipboard do it yourself

How to make a stool from chipboard do it yourself

Wardrobe room: types, location, arrangement of shelves

Wardrobe room: types, location, arrangement of shelves

How to paint furniture from MDF at home

How to paint furniture from MDF at home

Crochet a cape on the sofa

Crochet a cape on the sofa