Overview of the most popular materials used to make furniture

Comfort, order tightly entered our lives. We used to sleep in comfortable beds, dine at the table, store clothes in a spacious closet. For the manufacture of all these items using special materials. They make them not only durable, functional, but also aesthetically appealing. Each type of material has its own characteristics, performance, price. In this publication, we take a closer look at the basic materials for the manufacture of furniture, their brief description.

Content

List of most popular materials

Functional cabinet furniture, other products are made from such raw materials:

- different types of wood

- different alloys of metals

- plastic,

- organic, real glass,

- wood waste,

- rattan,

- leatherette,

- textile.

The first five types of raw materials are used for the production of ordinary, cabinet furniture. Rattan is used in the process of creating woven objects. Usually they are used by designers in the interiors of private houses, cottages. Leather, textiles - the main elements of frameless products.

Metal

Office furniture made of metal will add originality to the interior.

Durable, stylish, elegant metal furniture products can be found anywhere. They are often decorated with interiors of offices, hospitals, banks, restaurants, apartments. Modern manufacturers have learned to make quite compact, lightweight objects out of metal. Previously, they were cumbersome. This was the main cause of unpopularity.

Unique strong bed with the forged elements

Forged, metal tables, benches, chairs, beds have a number of undeniable advantages.

- Damage resistance. In order to break, damage the metal, you need to try hard. For this reason, such furniture is preferred by many owners of cafes, restaurants, where there is always a large flow of people.

- Durability. Products are able to serve for decades, many are experiencing several generations of their owners.

- Ease of care. For cleaning it is enough to use simple soapy water, a soft cloth. Fear corrosion is not worth it. Modern alloys are fairly resistant to moisture.

The main disadvantage of metal furniture items is a rather high price. These are stylish, compact products.

Set of country furniture from metal with openwork legs and backs

Glass

Glass furniture is becoming very popular among buyers and interior designers.

Relatively recently, glass was used only as separate elements in the furniture industry. From it did shelves, doors, mirrors, doors. Today, the scope of glass has expanded significantly. From it make high-grade products for the house. Glass tables, shelves, cabinets have taken a worthy place in home, office and work interiors.

Glass is usually combined with various materials.

They have many positive characteristics.

One of them is a visual increase in space.This feature is especially important when designing small rooms of irregular shape. Another plus is airiness, lightness of products. They create the effect of weightlessness. Products do not overload the space, pass through a pleasant sunlight. The glass is strong enough, absolutely safe for health.

Glass furniture is a convenient item of stylish decor.

Of course, glass tables, chairs, other items have weaknesses. Their main problem is the instability to mechanical damage. A large load, a sharp blow, a fall from a great height are capable of completely destroying a beautiful structure.

Original designer furniture made from impact resistant matte glass

A rock

Elegant office table for negotiations from a natural stone

This is the brightest, most original of all materials for furniture. By production apply various artificial types of a stone. They make excellent benches for summer cottages, stunning worktops, practical bar counters, and reliable window sills.

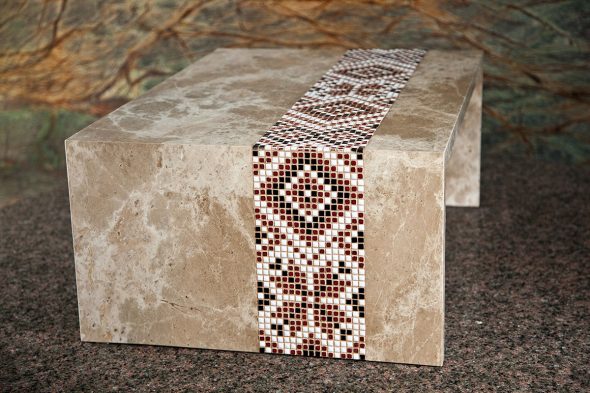

Marble table in folk style with handmade ceramic mosaic

Stone has several advantages.

- Health safety. This is a very important criterion when choosing any household items for the home. The stone is non-toxic, does not emit harmful substances into the air.

- High hygiene. The surface of products is always monolithic. It will not absorb dirt, grease, odors. For this reason, stone countertops, bar counters are often purchased for the kitchen, dining room.

- High resistance to mechanical damage. Stone construction is difficult to cause significant damage. For this you need to seriously try. If there is a scratch, it is easy to remove.

Chic garden stone furniture

The most significant drawback of the stone is the high price. Private family stone countertops, garden benches will not afford.

A unique stone coffee table will add zest to any interior.

Plastic

Multicolored plastic chairs in a modern style.

This is an artificial material, widely used in the production of various household items. From it comes practical, cheap, light furniture. Usually it is purchased for use in bathrooms, toilets. You can often meet in a cafe, on the dacha plots. Everywhere she looks organically.

Plastic garden furniture available and comfortable.

Plastic chairs, tables are not afraid of harsh weather. They do not lose their original appearance even after frequent exposure to moisture, water. From plastic it is easy to build a design of any shape. The production process does not require large investments, is technologically simple.

Light plastic furniture

Such material has few drawbacks: it is very fragile, has an unattractive appearance, and serves for a relatively short time. However, today more advanced types of plastic have been developed. They are deprived of these shortcomings, they are more expensive.

Original plastic chairs for the street or at home

Forest industry waste

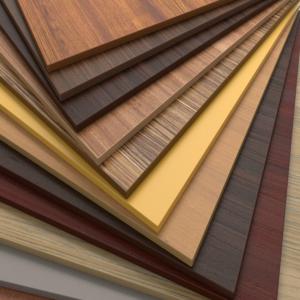

Types of materials used for the manufacture of furniture

Everyone knows that for the manufacture of cabinet furniture the best material is wood. Solid wood has a number of advantages. It looks amazing, serves for a long time, has a beneficial effect on people's health. Such products are in great demand, despite the high price. However, time is rapidly moving, the forest area is inexorably becoming less. For this reason, steel production was actively used in the manufacture of furniture structures. From sawdust, shavings, other raw materials make practical, reliable material of different qualities. Consider the common advantages, disadvantages of the plates in the table.

| Wood Waste Slabs | |

| Benefits | disadvantages |

| · Conservation of natural resources | · Restrictions in creating unusual shapes, bends, |

| · Affordable cost, unlike solid wood, | · Difficulty in holding fasteners, |

| · Ease of manufacturing process | · Some species are not subject to restoration. |

| · Attractive appearance of the finished furniture. |

Features of chipboard

Chipboards for the production of inexpensive furniture

These plates are often used for the production of cabinet furniture of the budget category. Thanks to their appearance, the furniture industry has become accessible to a wide range of consumers. Tables, cabinets of chipboard are inexpensive, have a fairly attractive design. Another advantage of the plates - the presence of a wide variety of models. This allows you to arrange the premises in different styles, provides freedom in design, even for small means. Chipboard boards can serve for a long time, provided proper operation.

Among the weaknesses of particleboard experts point out their toxicity. It is particularly acute in the moments of heating. Constructions of chipboard should not be installed near batteries, any heating devices. Such a mistake would be too expensive. When heated, chipboard will release formaldehyde, phenols. They adversely affect human health. Another significant disadvantage is the impossibility of creating extraordinary, curved parts. This adversely affects the interior, making it standard.

Furniture set from a chipboard for a drawing room

Chipboard

LDSP boards have a wide range of colors and a longer service life.

Chipboard plates have shown low resistance to mechanical damage, have not enough stylish appearance. To improve these parameters, the plates were coated with a special coating. The covering allows to imitate various breeds of wood. This makes finished slabs much more attractive. Also, a special coating has improved the resistance to damage. The similar cabinet furniture serves longer, keeps the initial appearance throughout all term of operation.

Another advantage of chipboard - resistance to temperature extremes. Due to this, the plates are used for the manufacture of kitchen sets, cabinets, accessories. Headsets are lightweight, beautiful, relatively inexpensive. Disadvantages of chipboard are not many, but they are quite significant.

- The impossibility of the implementation of fine processing. Furniture designs sometimes come out of the same type, have clear boundaries, straight lines (like chipboard). To make something unusual of such raw materials is impossible. This limits the possibilities in design.

- The presence of harmful resins. It is not recommended to purchase products from laminated chipboard for a child’s room, they should not be installed near active heat.

Corner children's wardrobe of chipboard

Fiberboard: pros, cons

Fibreboard plates are suitable for the back walls of furniture made of chipboard or MDF

Fiberboard is made of wood waste that is subjected to heavy grinding. The manufacturing process is quite simple, does not require complex equipment, investing huge amounts. There are two production methods.

- Dry. In the process, resins are added, pressing is carried out when exposed to high temperatures.

- Wet. The process takes place without adding additional substances.

Fiberboard is difficult to call a high-grade raw material for furniture production. It is quite difficult to seal. For this reason, fiberboard is used when creating the rear walls, bottoms. Usually raw materials are used in combination with chipboard. Then it turns out quite reliable, inexpensive, functional design. Many people call fiberboard pressed cardboard. It really resembles cardboard appearance. It is also cheap.

MDF

MDF panels are used for the manufacture of furniture, and for interior work.

The most practical, good material for furniture production is MDF. It is created from very small chips, sawdust. Its main difference is absolute safety for the person. In the composition of the raw materials there are no harmful resins, substances. Lignin acts as a binder.It is a natural substance that is safe for human health. It is part of the intercellular substance of natural wood. That security has become the main reason for the high popularity of MDF.

Another important advantage of MDF - unlimited possibilities in creating design. It is easy to make various forms of it, form attractive curves. It is important to create an individual, unique interior of the living space. Water resistance, high strength - one more essential advantages of MDF. It will last a long time, can be used in rooms with high humidity. The main drawbacks are the high price, fire risk, the prohibition of partial restoration. Replace the damaged part of the MDF is impossible. Instead, you will have to purchase a new product. It is expensive for a family with a small income.

Beautiful bedroom set of MDF

Plywood

Plywood - safe inexpensive material for home-made furniture

For the manufacture of furniture used basic materials (wood, chipboard, etc.), auxiliary. Plywood belongs to the second group. They make the back surfaces of cabinets, side parts of drawers, cheap household shelves. The process of producing plywood is simple: craftsmen glue together several sheets of veneer. The material is durable, easy to handle, clean, safe for others. But the properties of plywood is not enough to use it as the main raw material in the furniture industry.

Original budget plywood kitchen

Video: Materials for the production of furniture. Plywood. Dsp. Furniture shield.

How to sew a beautiful and comfortable bedspread with your own hands

How to sew a beautiful and comfortable bedspread with your own hands

Sides in a bed for newborns with their own hands. Patterns and Tips

Sides in a bed for newborns with their own hands. Patterns and Tips

Decorative film for furniture: scope

Decorative film for furniture: scope

How to tie a crochet bedspread

How to tie a crochet bedspread