How to use evrovint in everyday life

Euro-screw is a fastener, it is also called confirmat, known since the early 1990s. This screw is also called evroshurupom or simply - "evrikom." The name comes from the brand Confirmat, under which it is produced by the German company Hafele. In the USSR, they confirmed the confirmatics only in 1973.

Euro-screw is a fastener, it is also called confirmatum.

Another option is to drill parts together.

Confirmat looks like a screw with a flat end, but with a countersunk head on six or four faces. It has turns of thread at the bottom with notches. In the upper part of the screw, near the head, there is no thread because of its uselessness, since the confirmat is much thicker than the screw and the upper part of the thread does not play any role in fastening reliability. Euro-screws for furniture are made of high-strength carbon steel, which allows, if used improperly, easily removed from the material.

Confirmat looks like a screw with a flat end, but with a countersunk head on six or four faces.

After connecting (tightening) the two parts, they can be corrected with a rubber mallet.

The advantages of the confirmat over an ordinary self-tapping screw are great, because it not only tightens the parts to each other, but also firmly keeps them from lateral displacements. Connected parts on the screw will not sit hard enough. Due to the fragility of chipboard, the use of screws does not meet expectations. Chipboard is quite soft material and the reliability of the screw depends on the place where it will be screwed. Confirmat will also hold securely and firmly even if there are pores in the chipboard.

It has turns of thread at the bottom with notches.

With the help of it, a small notch in the face and face is made.

Using the euro screws, you get high reliability of sections tightened by this fastener. The cost in relation to any product is a cheap one. Confirmat is easy to install and withstands heavy loads. The disadvantage is the unclosed fasteners, visible hat. It should be closed with a plug or sticker in the color of chipboard. Another disadvantage is a certain number of furniture assemblies, often no more than three times, because with frequent disassembly of furniture, the carving may break.

Euro-screws for furniture are made of high-strength carbon steel, which allows, if used improperly, easily removed from the material.

In order to avoid chipping from the back side, a chipboard or plywood sheet is enclosed.

How to connect?

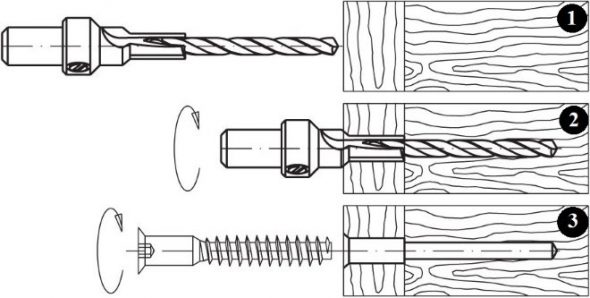

To connect two pieces of chipboard (thickness of one sheet of 16 mm) is used evrovint. One of the most affordable and affordable ways to date. To install it you will need:

- drill;

- 4.5 mm and 7 mm drills or “confirmatous” drill;

- handle, square, allen key.

The advantages of the confirmat over an ordinary self-tapping screw are great, because it not only tightens the parts to each other, but also firmly keeps them from lateral displacements.

Otherwise the confirmation will fall out, or vice versa, the chipboard will break, and you will ruin the furniture.

Need to pull two parts with a thickness of 16 mm. Vertically, the details recede 8 mm and draw the centerline, put a point. Making a hole with a drill with a diameter of 7 mm. On the second part we do the same, just take a drill with a diameter of 4.5 mm. If you have an “confirmatory” drill, the work is reduced significantly, but such a drill is not easy to find.All you need is to make a hole and connect the two parts together. The use of such a drill is rational in the case of a large amount of work and repeated use. To buy such a drill for "one-time" use is impractical.

Confirmat will also hold securely and firmly even if there are pores in the chipboard.

Here the main thing - to withstand all sizes.

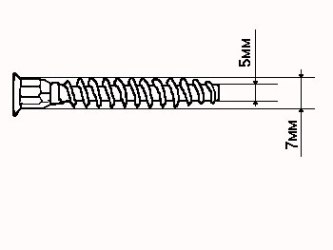

When assembling furniture is used confirmat 6.4 * 50. To connect the parts qualitatively, the hole diameter should be 4.5-5 mm. and a depth of 50mm.

Using the euro screws, you get high reliability of sections tightened by this fastener.

To connect the parts qualitatively, the hole diameter should be 4.5-5 mm. and a depth of 50mm.

Confirmats size

The required parameters are considered to be external threads.

The disadvantage is the unclosed fasteners, visible hat.

When assembling furniture is used confirmat 6.4 * 50.

The most popular sizes of euro screws:

- length: 40 (millimeters), thread diameter: 5 (millimeter);

- length: 50 (millimeters), thread diameter: 5 (millimeter);

- length: 40 (millimeters), thread diameter: 6.3 (millimeter);

- length: 40 (millimeters), thread diameter: 6.3 (millimeter);

- length: 40 (millimeters), thread diameter: 7 (millimeters);

- length: 50 (millimeters), thread diameter: 7 (millimeters);

- length: 60 (millimeters), thread diameter: 7 (millimeters);

- length: 70 (millimeters), thread diameter: 7 (millimeters).

The cost in relation to any product is a cheap one.

To buy such a drill for "one-time" use is impractical.

Here the main thing - to withstand all sizes. Otherwise the confirmation will fall out, or vice versa, the chipboard will break, and you will ruin the furniture. Confirmation drill also makes a notch under the cap. Holes are made strictly according to the marking and the drill must be kept parallel with the surface. In order to avoid chipping from the back side, a chipboard or plywood sheet is enclosed. The important point: when drilling the butt of the part, the drill should stand strictly perpendicular to its end, otherwise if you deflect the drill goes to the side and the part will be damaged. In drilling in the details of the part is important perpendicularity of the drill to the details. To avoid a drill coming off, use a regular awl. With the help of it, a small notch in the face and face is made. After connecting (tightening) the two parts, they can be corrected with a rubber mallet.

Connected parts on the screw will not sit hard enough. Due to the fragility of chipboard, the use of screws does not meet expectations.

The use of such a drill is rational in the case of a large amount of work and repeated use.

Another option is to drill parts together. This method is not only fast, but also accurate. Only for this it is necessary to secure the parts with clips. Thereby you save your time and speed up the assembly process.

To connect two pieces of chipboard (thickness of one sheet of 16 mm) is used evrovint.

If you have an “confirmatory” drill, the work is reduced significantly, but such a drill is not easy to find.

As a result, the use of confirmatum is fully justified. To install it do not need special tools. All you need is to order the required number of confirmats. From the first time, it is unlikely that you will have a quality screed, but if you make a couple of screeds, everything will work out. As they say, the eyes are afraid, and the hands do.

Need to pull two parts with a thickness of 16 mm.

On the second part we do the same, just take a drill with a diameter of 4.5 mm.

From the first time, it is unlikely that you will have a quality screed, but if you make a couple of screeds, everything will work out.

VIDEO: Confirmat

How to paint furniture from MDF at home

How to paint furniture from MDF at home

Making ottoman from plastic bottles with their own hands. Instructions step by step

Making ottoman from plastic bottles with their own hands. Instructions step by step

Pantographs for cabinets coupe: what is it?

Pantographs for cabinets coupe: what is it?

How to tie a crochet bedspread

How to tie a crochet bedspread