How to get rid of cat urine smell on the couch

How to get rid of cat urine smell on the couch

Plaster partitions - what is it?

Structures made from plaster are designed to divide the space into several rooms.

In the market of materials for construction and repair, new types of building material systematically appear, the names of which sound to ordinary citizens incomprehensible from the point of view of their technical characteristics and possibilities for practical use.

Interroom partition of modern gypsum plasterboard slabs

Content

What is plaster and where is it used?

The relevance and convenience of erecting plaster partitions when there is a need to divide a large interior space of an apartment, especially in new buildings, do not raise issues for professionals, but apartment owners, who often do not repair or redevelop their apartments, have a question: “Plaster partitions - what is it and where are they used? ”

Plaster is often used to create internal partitions.

Plaster plates (in fact - plates cast from gypsum in a certain form) should not be identified with gypsum and alabaster plates, although natural gypsum is used as the main component in all these types of blocks. These materials of the plates differ in the percentage composition of the components, and accordingly - the technical characteristics.

Plaster blocks for interior partitions

In the composition of the plaster:

- gypsum - the main and binding component, natural, non-flammable material, does not emit odor, is not allergenic, does not conduct electricity, does not mold, and is not destroyed by fungi and insects;

- mineral additives that increase the density and strength of the structure, the workability of the finished product, since natural gypsum easily turns into a powder when working with it;

- hydrophobic additives, the purpose of which is to keep the internal structure of the product from prolonged exposure to moisture and destruction.

Plaster tongue-and-groove slabs are manufactured using injection molding technology from gypsum grades G-4 or G-5

Production and design features of plaster

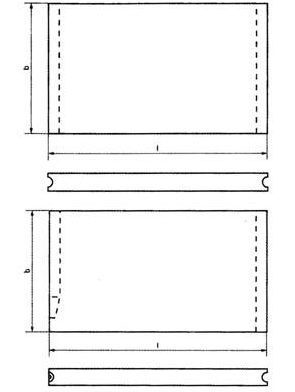

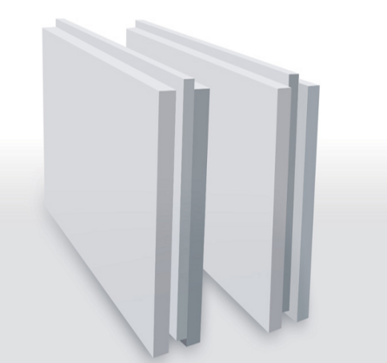

Single and double partition wall structures made of gypsum plasterboard slabs

Manufacturing technology, composition, dimensions, characteristics, methods of control and acceptance of plaster products are governed by GOST 6428-83. Products obtained according to the standard technological documentation, allow you to quickly, easily, inexpensively, constructively reliably produce high-quality, eco-friendly repair of the wall of the room or its redevelopment with the construction of durable, lightweight, fire-resistant partitions. This standard was adopted in 1983. Currently, manufacturers of plaster blocks and slabs, along with GOST, are developing specifications that allow us to manufacture products with more advanced consumer sizes and characteristics.

The state standard establishes 2 versions of plasterboard:

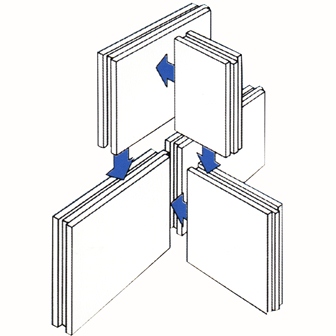

- With grooves on the edges for joining two blocks, filled after connecting with a solution.

Drawing of mortise plasterboards that have already been discontinued

- With grooves and ridges of rectangular or trapezoidal shape. Such a docking connection is determined by the state standard specification as a product of the highest quality. The shape of the comb does not affect the quality and strength of the compound solution.

Plaster blocks with a rectangular and trapezoidal groove / ridge shape

The standard establishes the maximum deviations from the accuracy of the dimensions of the grooves and ridges, and for the connection of the 2nd variant they are more strict than for the 1st variant. The price for products of the first category is less than the price of blocks of the highest category.

If the width of the doorway does not exceed 80 cm and only one row of tongue-and-groove slabs is installed above it, then the norms allow not to use a jumper

When the width of the opening is greater than 85, it is necessary to install a steel or wooden beam jumper

The current standard provides the following dimensions of plates, respectively, in length and height:

- 600 x 300 mm;

- 667 x 500 mm;

- 800 x 400 mm;

- 900 x 300 mm.

Partition diagrams of 667 x 500 (h) plates

Plasterboard plates are different:

- According to the structure:

- hollow with a thickness of 80-100 mm, which, compared to hollow blocks, has lower weight and better sound and heat insulation qualities;

Hollow moisture resistant tongue-and-groove plates

- Hollow 35-40 mm thick, have greater strength and reliability.

Pazogrebnevy monolithic hollow gypsum boards

Hollow and corpulent plaster blocks in comparison

- According to the degree of moisture absorption:

- ordinary (25-33%) - for rooms dry and with a normal level of humidity;

Conventional plasterboards are used for the construction of partitions in rooms with normal humidity.

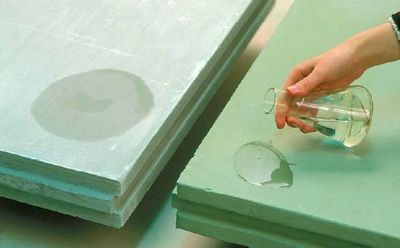

- moisture resistant (less than 5%) - for rooms with a humidity of more than 60% (portland cement is added to their composition, and is colored green to distinguish it).

Moisture-resistant plasterboards are used for the construction of partitions in rooms with high humidity

The choice of plaster partitions - what should I look for

Beautiful partition of plasterboards

The practice of using plaster blocks has shown that you should choose:

- for the wall in the kitchen and bathroom - moisture-proof (hydrophobic) blocks;

- in the presence of a wooden floor - hollow blocks, any kind is suitable for a monolithic floor;

- for interior partitions - both types: hollow and hollow, given that at high ceilings at the bottom it is better to have stronger hollow blocks.

Connection of rectangular monolithic plates with tongue-and-groove joint

Preparation for installation

The process of installing plaster blocks

As mentioned above, plaster partitions are easy and simple to install because of the convenient size, the presence of strong joints. An electric cable can be conducted inside and outside the partitions, through them - thin pipelines.

The system of grooves and ridges allows you to quickly and tightly strengthen the panel

It should also be noted the perfect geometry of the plates, a smooth surface that does not require subsequent plastering of the wall (only the putty of the seams).

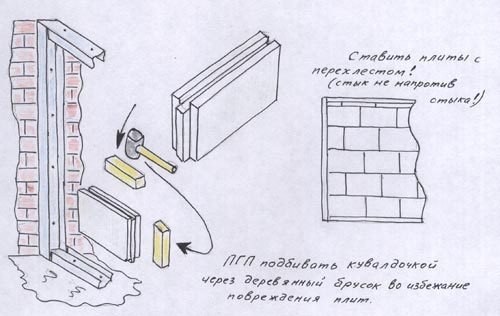

Installation of plasterboards is carried out with bandaging docking seams using staples

Plaster is easily sawn with a hand or electric hacksaw.

Cut the blocks with a hacksaw

What you need to do before installation

The installation scheme of gypsum plasterboard slabs

- Charting the partition and determining its dimensions (professionals do not advise installing a partition wall with a length of more than 6 m and a height of more than 3.5 m), take into account that a rounded or curvilinear structure will not work.

- Select the type of blocks, their desired number, mounting glue for fastening blocks.

- Prepare the necessary tools for cutting, chroming, stripping seams, measuring the level of the floor, as it is necessary to install the blocks on a perfectly flat base, to prepare other measuring devices.

- If necessary, prepare such materials as a dry cement mixture for leveling the floor, the substrate.

- Mark the floor for the door opening, if it is planned in the partition.

- Bring the blocks into the room before installing for several hours to equalize the temperature inside and outside the block.

Plasterboard wall

Repair damaged plate

Do-it-yourself damaged plasterboard repair

- Remove dirt and dust from the damaged area.

- Treat the cleaned area and the area next to it (several cm) with a deep penetration primer to stabilize the structure of the plaster.

- Prepare a mixture of gypsum and PVA.

- Moisten the damaged area with water, seal the damage with a solution of gypsum, for strengthening - attach a nylon mesh to the dry area and press it into the repair mixture so that it does not stand out after drying.

- After drying, clean the surface.

- Restore the decorative coating.

Video: Interior partitions from KNAUF-gypsum panels

How to get rid of cat urine smell on the couch

How to get rid of cat urine smell on the couch

Furniture thrust bearing: what it is and how it works

Furniture thrust bearing: what it is and how it works

How to choose a mattress for a double bed?

How to choose a mattress for a double bed?

To help the hostess - ironing board, built-in wardrobe.

To help the hostess - ironing board, built-in wardrobe.

Choosing screws to assemble furniture wisely

Choosing screws to assemble furniture wisely