How to attach the canopy to the crib

How to attach the canopy to the crib

What is chipboard in furniture?

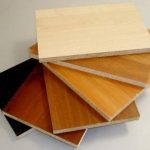

The usual first chipboard plates appeared in 1918. Thanks to progress over many years, materials have become better, more reliable, and today moisture-resistant laminated boards are available for the production of various products. There are many types of plates made of wood. These include MDF and laminated chipboard with different characteristics and their own characteristics.

In order for the choice of material for your own cabinet or chest of drawers to be meaningful, you need to know the advantages and disadvantages of furniture materials.

Laminated particle boards based on thermosetting polymers are the main and often used material for the production of mass elements of the situation in the industry, it is also widely used in construction. Such plates are sufficiently resistant to mechanical and chemical influences (gasoline, acetone, water, solvents, alcohol, acid, coffee and other substances). From this we can conclude that chipboard is an excellent raw material for the production of medical, laboratory, educational, household and office furniture.

Due to its low cost and excellent building properties, chipboard is the most widely used material for the manufacture of furniture of economy class.

Laminated chipboard is a representative of the old well-known chipboard (chipboard) in a more polished form.

LDSP - material which is made on the basis of natural wood. This is the same chipboard, but whiter polished, on the surface of which resistant melamine film. That is the main difference between them - coverage. When it is pressed into the very structure of the board - it makes it more waterproof and much stronger. This “friable” raw material, its cost is low-cost, according to the design, due to the film and the coating, various color solutions can be achieved, including with the pattern of natural wood. It is widely used in the manufacture of housing products for the kitchen, office, home, and other home furnishings as the main material. From it make stands for exhibitions, furniture for the interior of shops, pharmacies and supermarkets. With MDF is the same, but at the same time such boards are more expensive.

Most of the office furniture is made from chipboard.

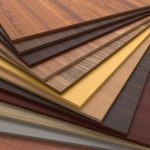

Chipboard lamination is made in different colors and different textures:

fantasy vector decors;

- geometry;

- ornaments;

- plain paper;

- drawings and wood imitation.

However, this material has its drawbacks - these are harmful formaldehyde emissions.

Decorative lining film is impregnated with resin, it is made of special decorative paper with a density of 60-90 g / m2.

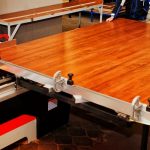

Lamination - the process of applying a decorative coating under the action of pressure and temperature.

Lamination occurs in the press. In the process of pressing the paper becomes denser, according to its properties, it is on a par with plastic. A thick glossy film is formed on top, the bottom is the same, but of a different structure - glue. The coating of laminated boards is quite strong, it is formed due to the spreading of the resin over the entire surface of a chipboard with a pressure of 25-28 MPa and a temperature of 140-210 ° C. For production, their width cannot be less than 10 mm, but not more than 22 mm. When laminating from chipboard, aldehyde vapors are not released, which are harmful to the environment.

Lamination is considered a more reliable and expensive way to manufacture chipboard.

It is pressed into the structure of the plate, making it more durable and moisture resistant.

Content

Types of chipboard in furniture

Manufacturers mark the structure of chipboard differently, but usually like this:

- BS is office;

- SE - tree with surface pores;

- SM - smooth surface;

- MAT - matte smooth surface;

- PR is a porous structure;

- PE - “orange peel”.

Regardless of the method of application, such a chipboard is called a melamine coated chipboard.

For the production most often used are the first two: BS and SE. PR is also popular, but is used less frequently, SM is used in the production of internal partitions. Other markings may occur.

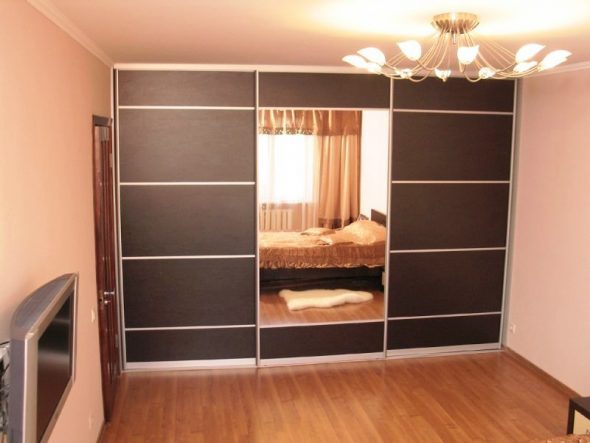

It is widely used for the manufacture of furniture, door filling of the coupe type and other elements of interior decor.

Advantages and disadvantages of chipboard in furniture

To choose a good raw material for a particular furniture you need to know its features, including pros and cons. Any material from particle board is made from sawdust and wood chips impregnated with formaldehyde resin as a binder. Chipboard emit formaldehyde, which is bad for the environment and human health, but there is a protective film in the laminated chipboard - a laminated layer that does not allow the substance to evaporate from the boards.

The variety of colors and textures, imitation of the texture of natural wood.

This is not plastic, not iron, but all the same familiar to all wood.

To make a laminated film used paper of a certain texture and ornament. It is impregnated with melamine resin, as a result of which it becomes a certain level of stiffness and more friable. Then, under the press, the surface of the board is joined to the film - this is how a laminated sheet of standard thickness is formed.

Resistance to mechanical damage.

LDSP is a fairly resistant material to mechanical and thermal effects with a large assortment of textures and colors. It can be developed in the form of valuable wood. Due to the resistance to high temperatures on the countertops of this raw material you can put hot dishes.

Resistance to thermal effects (to hot coffee pots and pans).

LDSP is the materials made on the basis of a natural tree.

The disadvantages include the lack of fine processing and the presence of formaldehyde resins in the composition of the chipboard, and the advantages in high mechanical and chemical resistance.

Laminated chipboard is a representative of the old well-known chipboard (chipboard) in a more polished form.

Furniture from MDF - what is it?

MDF - an improved technology for the production of chipboard materials. The board consists of small pressed fractions of sawdust. Thanks to this method of bonding material is obtained high strength, uniform and harmless to health. Thanks to these indicators, it can be used for the production of any furniture, including for the children's room. Its cost is slightly higher.

The main difference between chipboard and chipboard is that the coating is pressed into the structure of the slab, making it more durable and moisture resistant.

The main advantages are the high strength of plates, uniformity, ease of processing, moisture resistance, anti-deformation abilities, a wide range and beautiful design.

MDF is a rather dense material - this makes it indispensable in the production of furniture that requires turning fine lines, roundings, etc.

Cons: high price, boards are afraid of mechanical damage and shocks, easily ignite.

MDF is an environmentally friendly material and has no restrictions on the use.

How to choose the chipboard?

To date, there is a considerable amount of particle board for various purposes. Their differences are in thickness, composition, wear resistance, density. Such features are associated with the use in various areas of plate production. There is a stereotype about the density of the plate.It is believed that the denser it is, the better. But it is not so. The advantage of these boards is in low-cost raw materials (low-grade wood). It includes "tonkomery", slab, slats. The main thing is that these materials meet the following standards.

- Fractions of chips should not be small.

- The cross section of the chips should be square, and the shape of the petal. If these requirements are violated, the physicochemical properties of the finished plate will deteriorate (bending and resistance will suffer).

Often consumers ask questions: what kind of material is this for a bed - MDF? What is the difference between MDF and chipboard for furniture? Consider these details in more detail.

The film is a paper impregnated with melamine resins, therefore such a term as “melamine plate” can often be found.

Advantages of chipboard:

- low price;

- does not crack, does not stratify, does not grow moldy;

- due to chemical additives in the slab, bugs do not live;

- service life of more than 10 years.

Pros MDF:

- reasonable price for consumers with average incomes;

- strength;

- moisture resistance;

- includes all of the above advantages chipboard.

LDSP can be washed and cleaned - it is moisture resistant.

The choice of material depends on what is planned to produce. Chipboard can be used in the manufacture of furniture designed for the office, home, shop, supermarket. MDF is better to choose for children's furniture.

Heats are also not afraid of it.

The production of fibreboard allows you to manufacture products at affordable prices for various interiors. Thanks to furniture MDF and chipboard every home will be filled with coziness, warmth and comfort.

His advantage, in addition to all of the above, is his great opportunity to imitate various textures, most often - imitation of wood texture.

Pay attention to the norms of formaldehyde in cabinet furniture.

VIDEO: Furniture made of wood or furniture from chipboard.

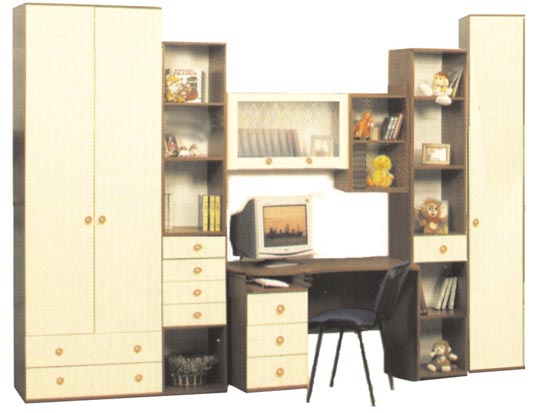

Chipboard furniture: 50 photo ideas

How to attach the canopy to the crib

How to attach the canopy to the crib

How to remove white spots on furniture

How to remove white spots on furniture

Paint for children's furniture

Paint for children's furniture

Pantographs for cabinets coupe: what is it?

Pantographs for cabinets coupe: what is it?